A Ballastless Track Vibration Damping Structure with Uniform and Continuous Rigidity

A ballastless track and vibration-reducing structure technology, applied in the direction of tracks, roads, ballast layers, etc., can solve the problems of track surface waveform wear, increase wheel-rail noise and vibration, and surrounding environmental noise pollution, etc., to reduce waveform wear, The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in conjunction with accompanying drawing and specific embodiment:

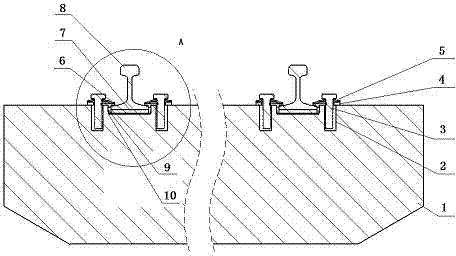

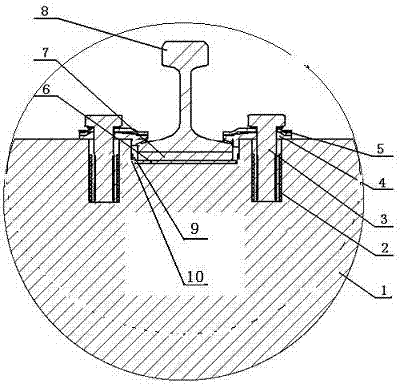

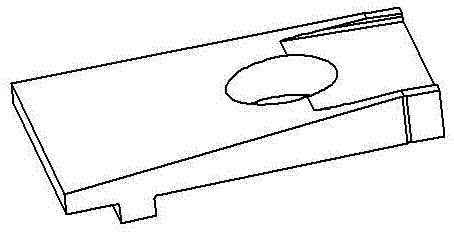

[0025] Such as figure 1 , figure 2 As shown, a ballastless track with uniform stiffness and continuous vibration damping structure mainly includes a rail 8, a ballast slab 1, and a gauge block 4 and an elastic bar 5 that limit the rail to move up and down and horizontally; on the ballast slab 4 There are two parallel grooves for laying steel rails, and a plurality of continuously laid steel rails 8 are located in the grooves; elastic under-rail pads 7 and under-rail pad boots 6 are arranged between the steel rails 8 and the bottom surface of the grooves; The above-mentioned under-rail cushion boots 6 are continuously laid in two longitudinally arranged grooves on the track bed, and the under-rail cushion boots 6 have a "U"-shaped structure; the elastic under-rail cushion 7 is laid along the rail The direction is continuously set and located in the under-rail shoe 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com