Method for high precisely detecting geometric outline of rail

A detection method and high-precision technology, which is applied in the analysis of rail gauge and track wear, and the detection of rail geometric profile. It can solve the problems of numerous exchange relations, relatively high device requirements, poor robustness, error transmission, etc., and achieve detection The effect of high precision, simple and flexible installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

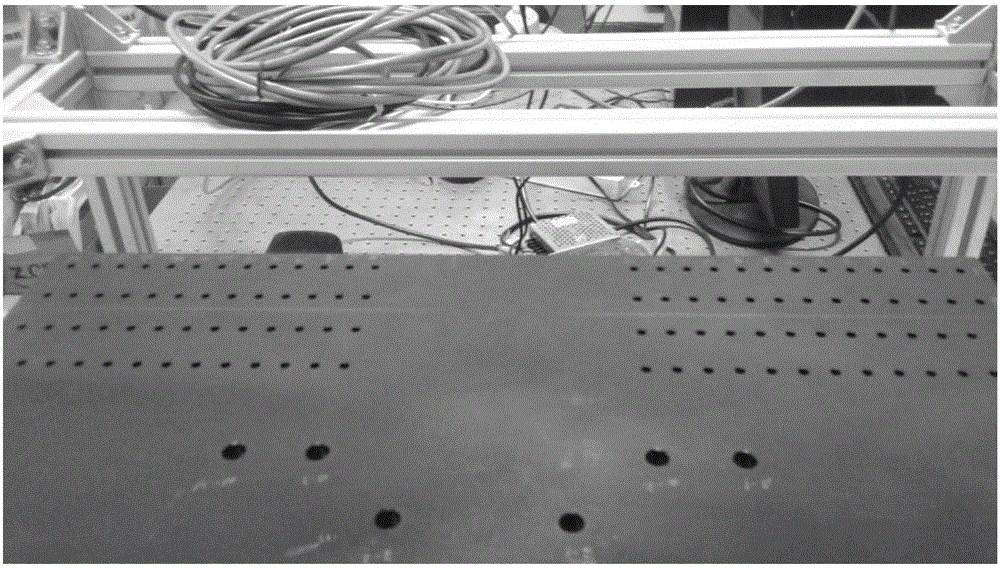

[0062] 1. Complete the parameter selection of the laser, camera and lifting platform according to the requirements of the rail geometry inspection, including the following sub-steps:

[0063] (1.1) According to the accuracy requirements of the rail geometry detection, the important index parameters of the camera are selected: the resolution is 1628×1236, and the image size is 1 / 1.8 inches. F number = 3.27, using f = 28mm fixed focus lens. The depth of field is at 106mm. See Figure 7 .

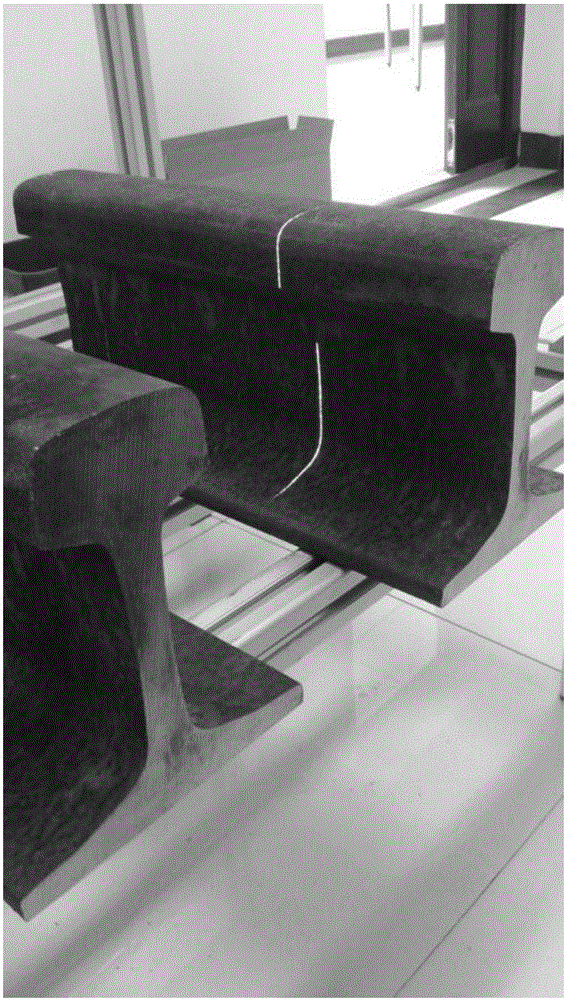

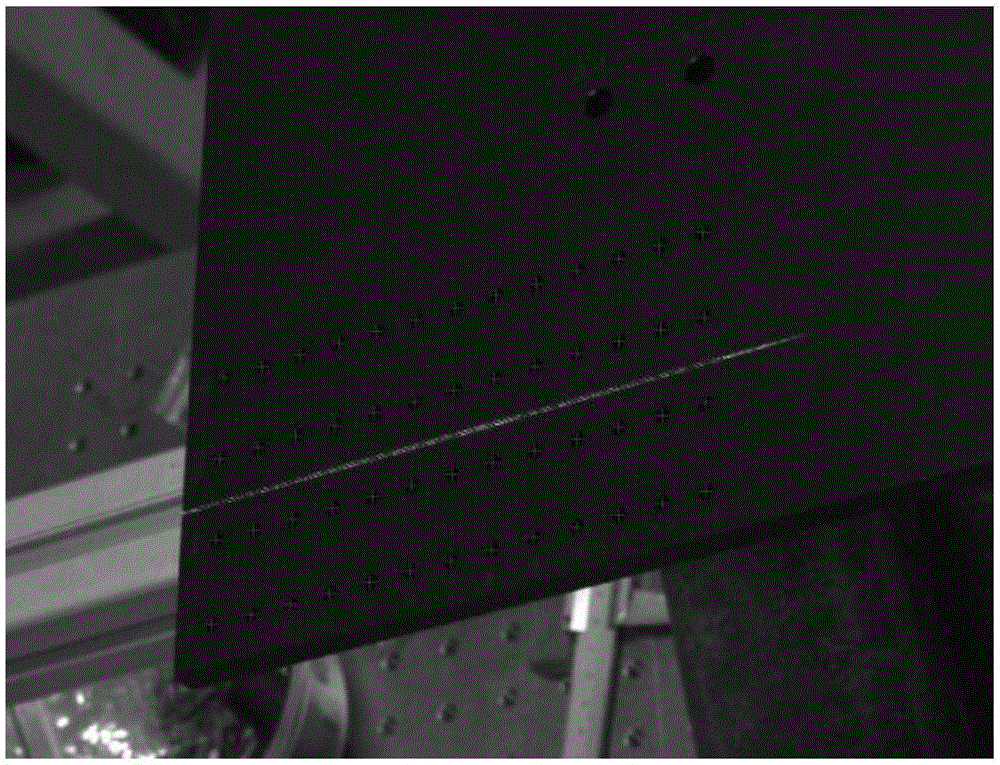

[0064] (1.2) According to the requirements of image quality and laser image coordinate extraction accuracy, the line width of the selected laser is less than 1mm, and the laser wavelength is 632nm, see Figure 8 .

[0065] (1.3) According to the detection height requirements of the rail, the stroke of the lifting table exceeds the height range of 176mm.

[0066] 2. Select 4 line lasers and 4 cameras, and realize the connection between the line laser and the camera through a rigid support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com