A wheel profile multi-objective optimization method based on improved particle swarm optimization algorithm

A multi-objective optimization and particle swarm algorithm technology, applied in the field of train wheel design, can solve problems such as performance index decline, achieve the effects of reducing wheel and rail wear, prolonging normal service life, and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

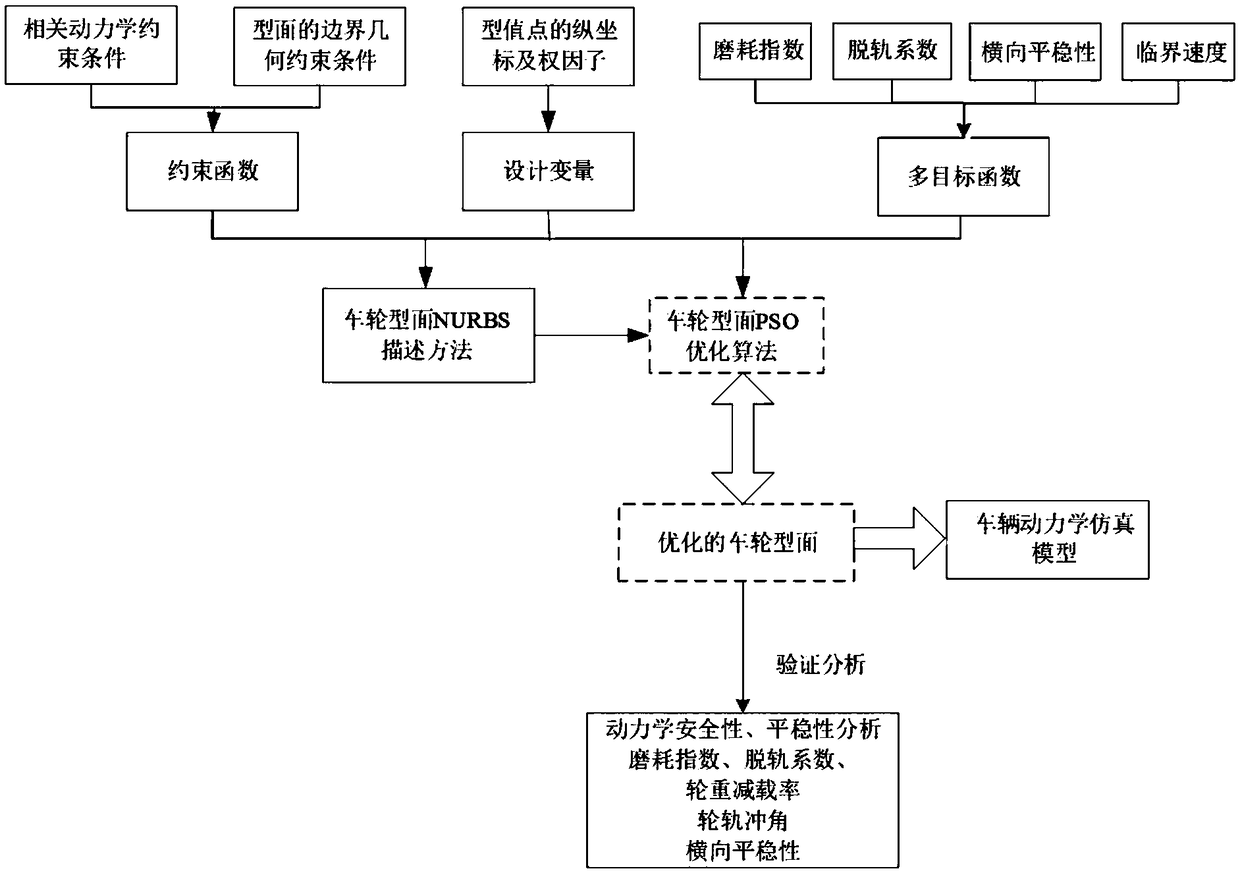

Method used

Image

Examples

Embodiment 1

[0113] Application of the present invention is based on the wheel profile multi-objective optimization method of improved particle swarm algorithm, and utilizes the simulation data that the computer simulation model gained by Simpack is set up to carry out experiment: select 3 kinds of line geometry models to set radius and be respectively 400m, 600m, 800m ideal For the curved line, the vehicle running speed is 60km / h, and the U.S. Class 5 track spectrum is selected as the track line excitation.

[0114] Select the RMS value of the wear index of the left wheel of the No. 1 wheel set as the research object, and compare and analyze the wear index of the two profiles under different curve radii. The simulation results are shown in Table 2:

[0115] Table 2 The wear index data of the first wheel pair and the left wheel when the two types of surfaces pass through with different curve radii

[0116]

[0117] Compare and analyze the statistical data in the table, draw the followin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com