Deviation correction method for measurement of rail wear based on laser vision

A rail wear and laser technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of reducing the accuracy of rail wear measurement, it is difficult to ensure verticality, etc., to improve utilization, improve accuracy, and eliminate rail wear measurement effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

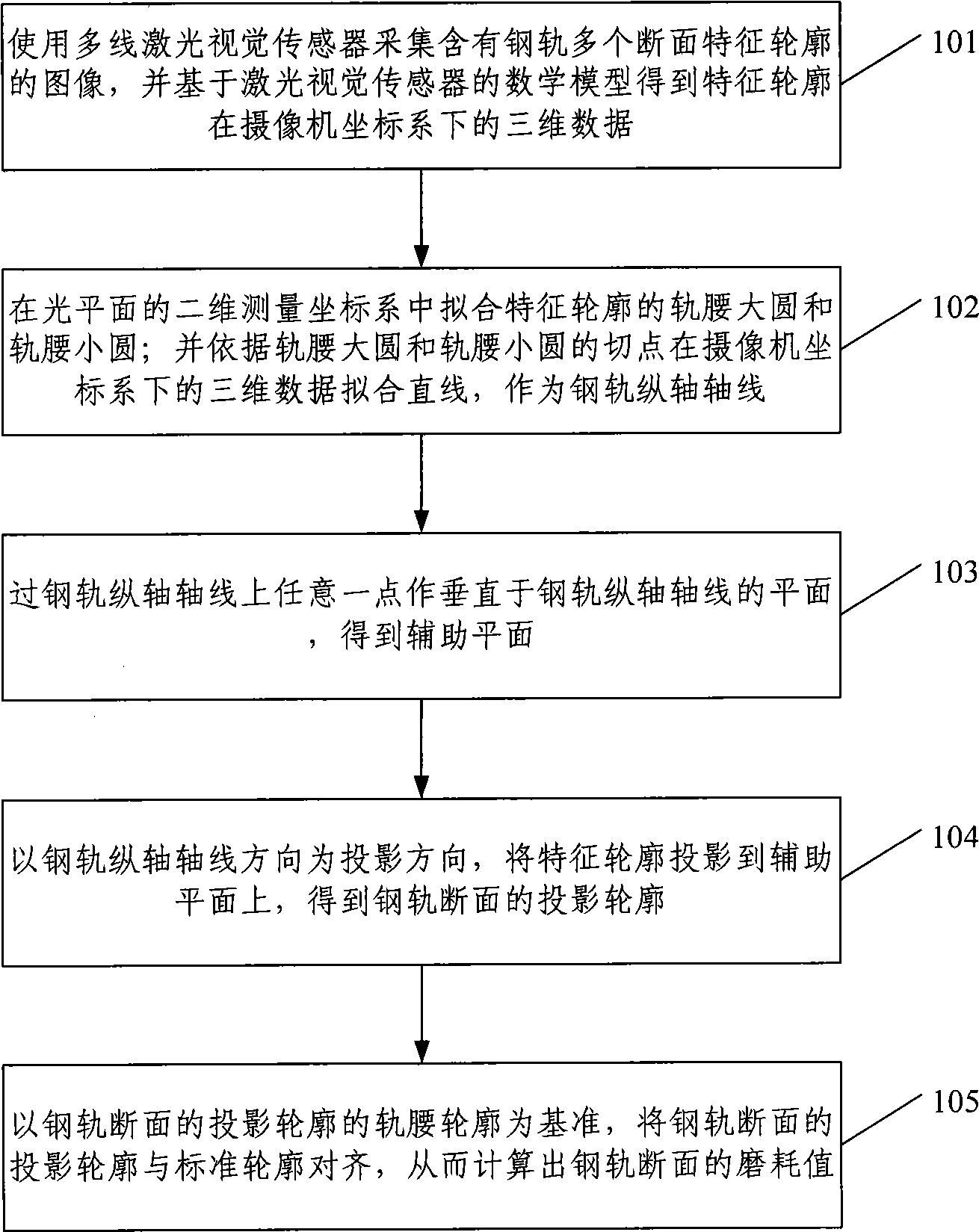

[0032] A deviation correction method for laser vision rail wear measurement provided by the present invention, such as figure 1 As shown, it mainly includes the following steps:

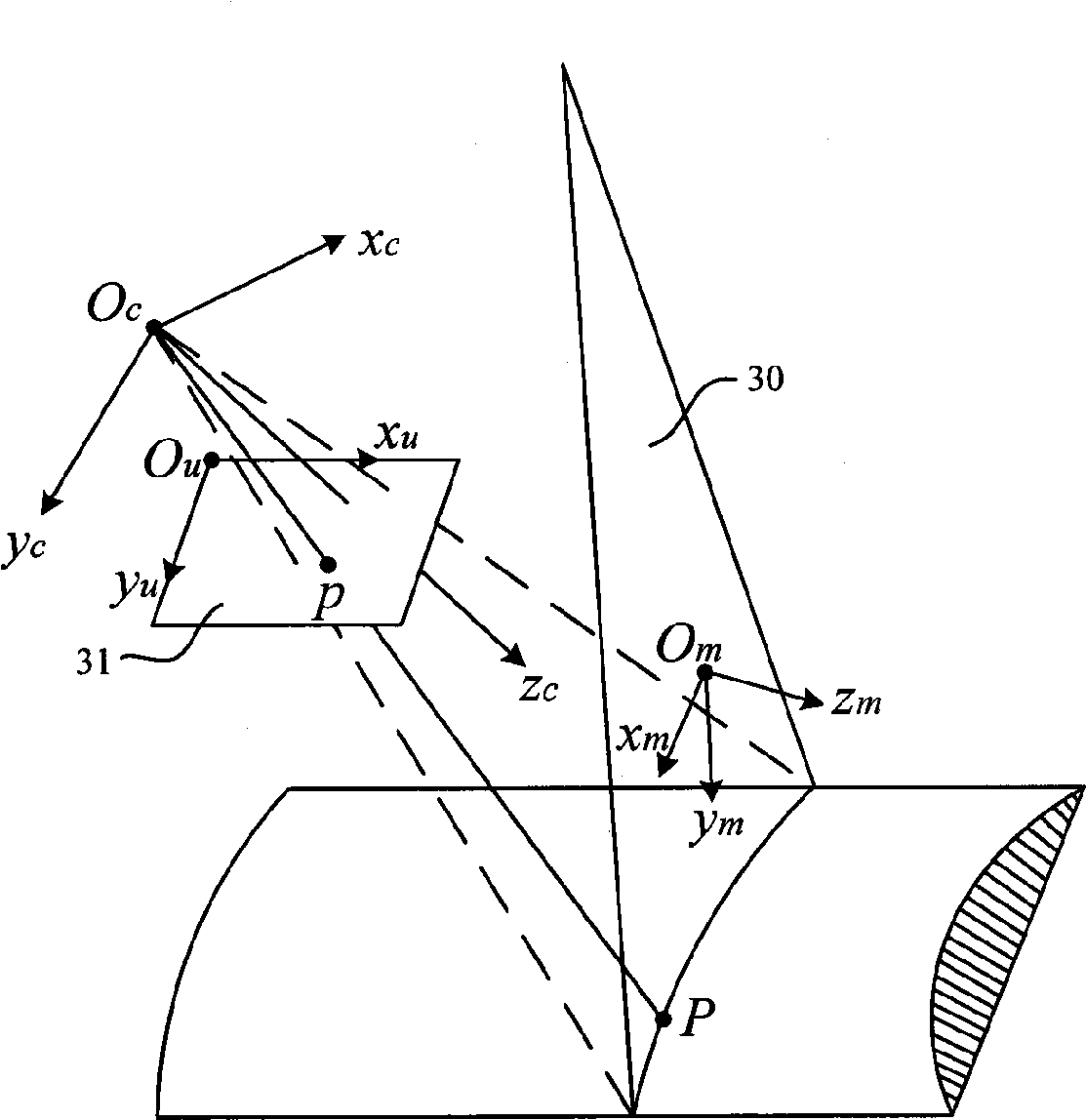

[0033] In step 101, the multi-line laser vision sensor is used to collect images containing feature contours of multiple cross-sections of the rail, and the three-dimensional data of the feature contours in the camera coordinate system is obtained based on the mathematical model of the laser vision sensor.

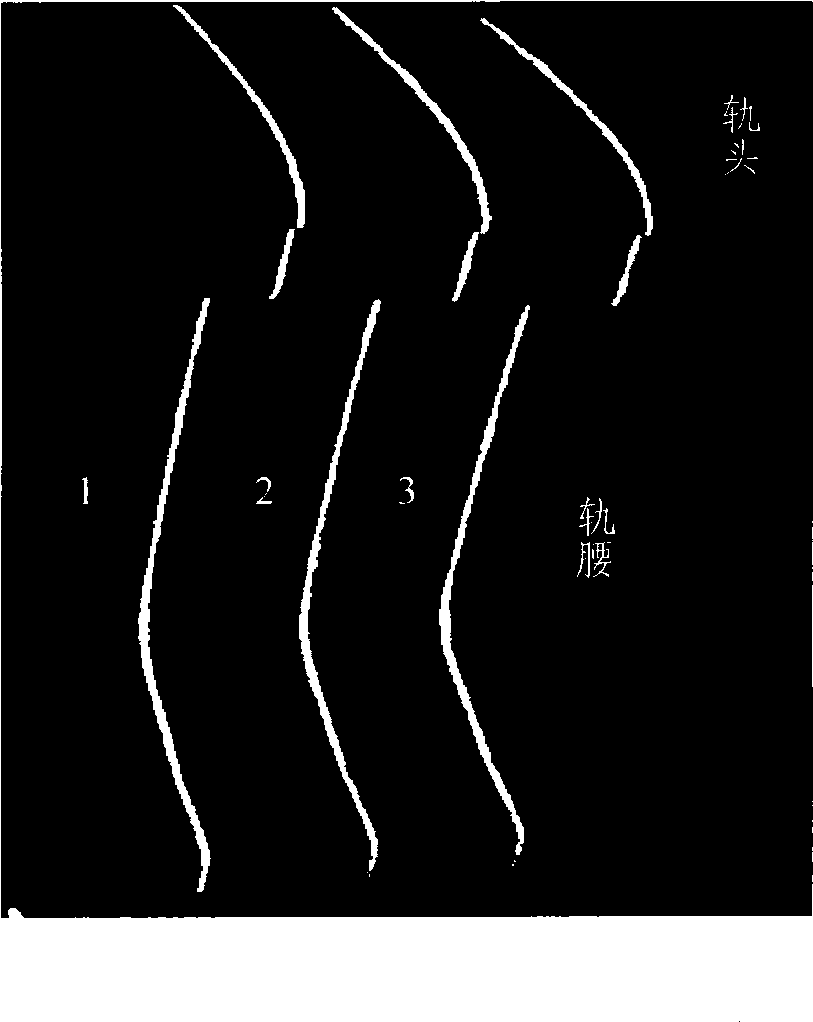

[0034] In the present invention, a multi-line laser vision sensor is used to measure multiple sections of the inner rail waist and rail head of the rail. The multi-line laser vision sensor contains two or more than two light plane projectors, which can project a plurality of parallel light plane. Preferably, a laser vision sensor capa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com