Safe and efficient operation active adhesion controlling method and system for motor train unit

A technology of adhesion control and efficient operation, which is applied in general control systems, control/regulation systems, adaptive control, etc., and can solve problems such as the difficulty of wheel-rail surface adhesion characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] A method and system for active adhesion control for safe and efficient operation of multiple trains according to the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0052] The following is the best example of an active adhesion control method and system for the safe and efficient operation of an EMU train according to the present invention, which does not limit the protection scope of the present invention.

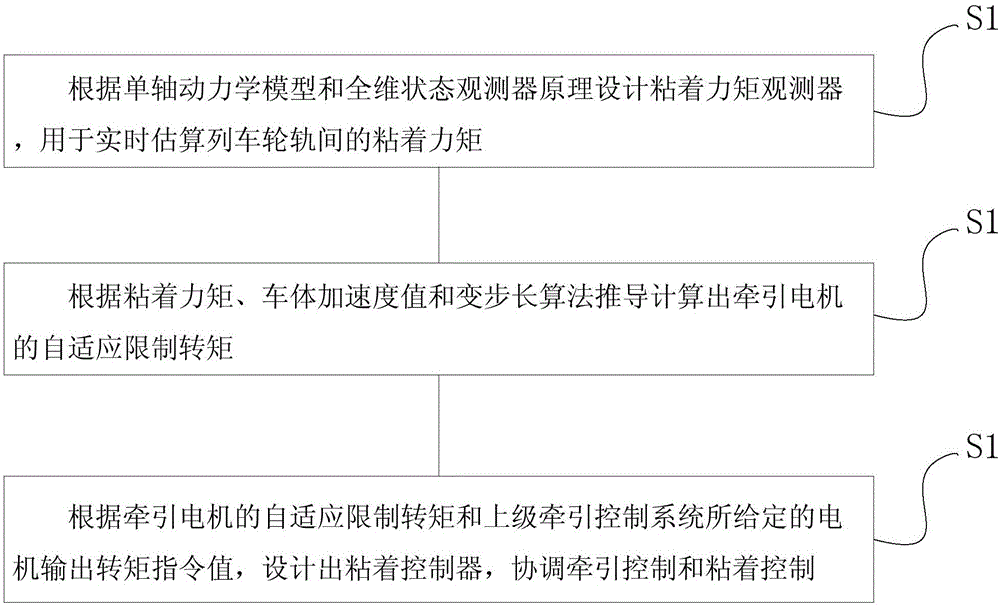

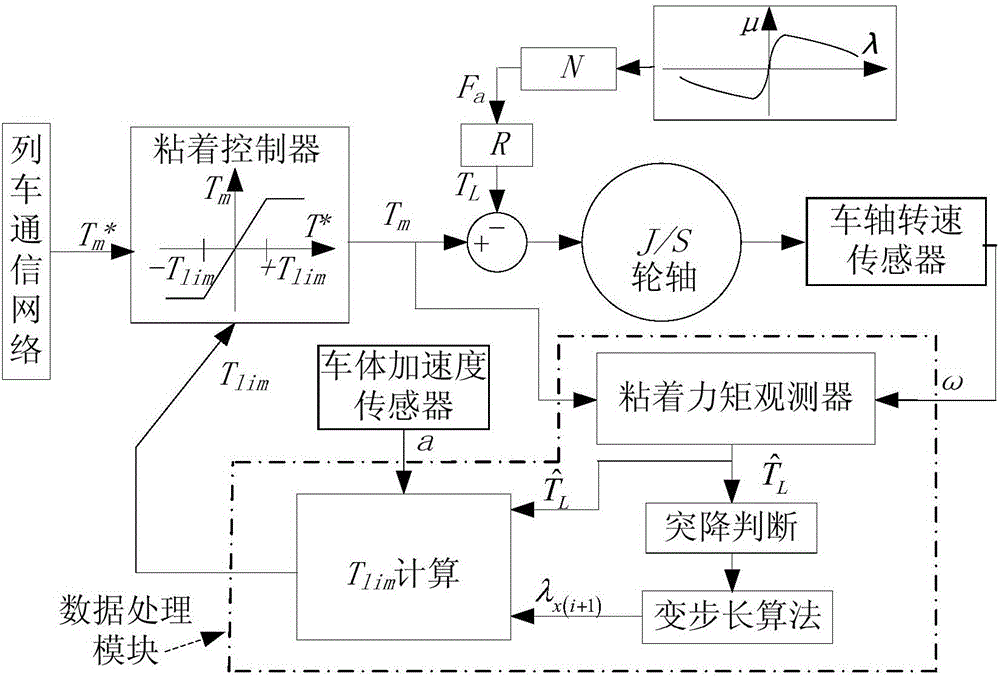

[0053] figure 1 A flow chart of an active adhesion control method for safe and efficient operation of an EMU train is shown, including the following steps:

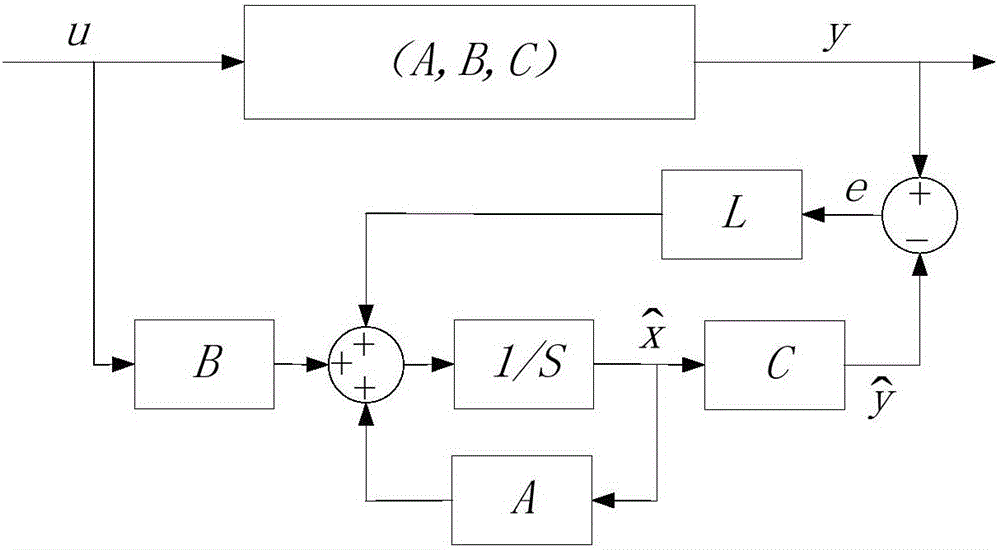

[0054] S1. Design the adhesion moment observer based on the uniaxial dynamic model and the principle of the full-dimensional state observer, which is used to estimate the adhesion moment between the train wheels and rails in real time

[0055] S2, according to the adhesion torque The adaptive limit torque T of the traction motor is calcula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com