Ultrasonic phased array detecting and monitoring method

An ultrasonic phased array and ultrasonic technology, which is applied in the direction of analyzing solids using sound waves/ultrasonic waves/infrasonic waves, can solve problems such as the inability to detect the quality of friction stir welded thin plate joints, and achieve the effects of difficult detection, improved efficiency, and accurate quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

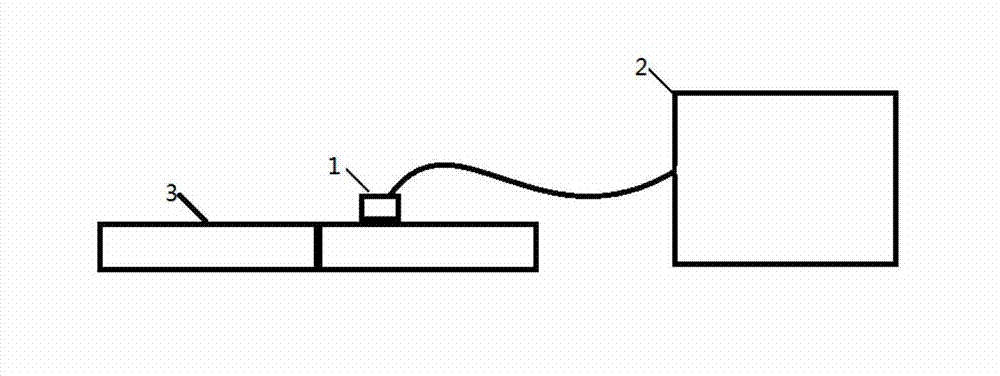

[0017] refer to figure 1 , the ultrasonic phased array probe 1 is connected to the ultrasonic phased array instrument 2 through a cable, the ultrasonic phased array probe 1 is placed on the friction stir welding test piece 3, and the ultrasonic phased array probe 1 and the friction stir welding test piece 3 are coated with The couplant ensures that the ultrasonic energy is transmitted into the friction stir welding test piece 3. In the actual detection process, the ultrasonic phased array instrument generates a discharge pulse signal with an amplitude of about 200KV, which excites the ultrasonic phased array probe 1 to emit ultrasonic waves. The ultrasonic wave enters the friction stir welding test piece 3, and at the same time, the ultrasonic phased array probe 1 receives the ultrasonic echo signal, and the image of the ultrasonic echo will appear on the display interface of the ultrasonic phased array instrument 2, and the ultrasonic phased array instrument 3 is set to The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com