Aluminum cyclostyle and concrete wall bottom rot protective structure

A protective structure and aluminum formwork technology, which is applied in the direction of formwork/formwork/work frame, connection parts of formwork/formwork/work frame, building construction, etc. Problems such as slurry leakage, to achieve the effect of good integrity, excellent effect, and improved applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

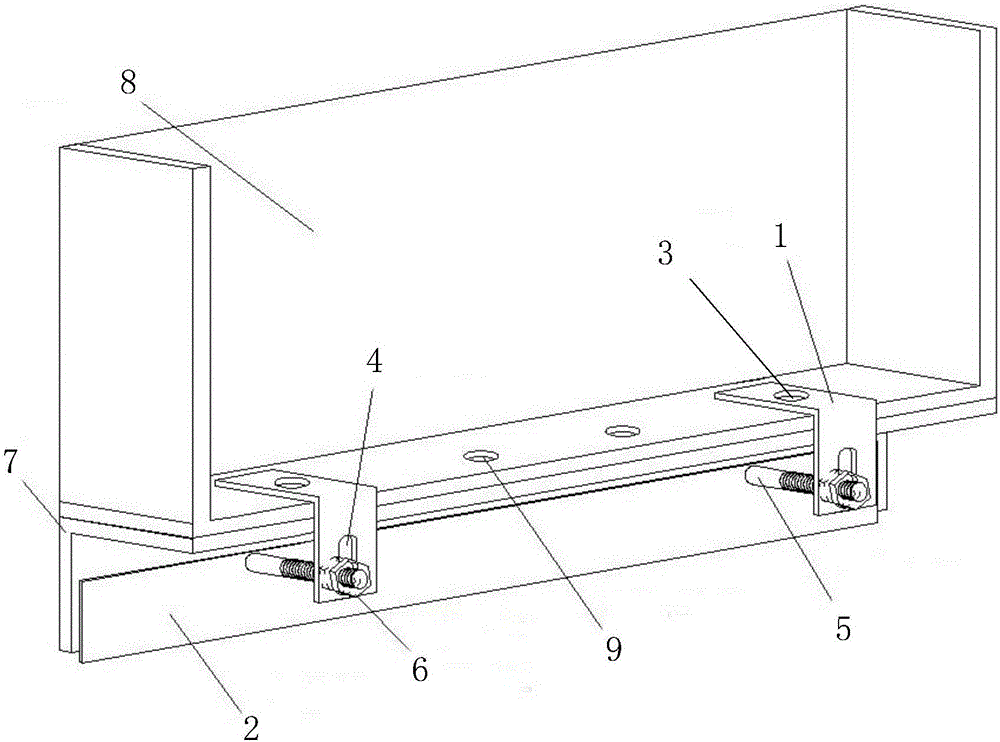

[0020] Such as figure 1 As shown, a protective structure for rotten roots at the bottom of an aluminum formwork concrete wall, including a buckle piece 1 fixed on the lower edge of the aluminum formwork (specifically at the joint between the aluminum formwork angle aluminum 7 and the aluminum formwork wall panel 8), and the fastening joint The mud baffle 2 that is movably connected; the fastening piece is "L" type, and a through hole 3 is provided at the end where the fastening piece is connected with the aluminum formwork, and a long strip hole 4 is provided at the other end; the mud The baffle is connected to the buckle piece through the connecting bolt 5; one end of the connecting bolt is connected to one side of the mud baffle, and the other end passes through the elongated hole and is threaded to the two nuts 6 on the connecting bolt and the buckle The tabs are connected, and the two nuts are respectively located on both sides of the elongated through hole.

[0021] By a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com