Defect two-dimensional morphology imaging detection method based on multi-mode acoustic beam synthetic aperture focusing

A synthetic aperture focusing and multi-mode technology, which can be used in measuring devices, analyzing solids using sound waves/ultrasonic waves/infrasonic waves, and material analysis using sound waves/ultrasonic waves/infrasonic waves. Quantitative result errors and other problems, to achieve high engineering application and promotion value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

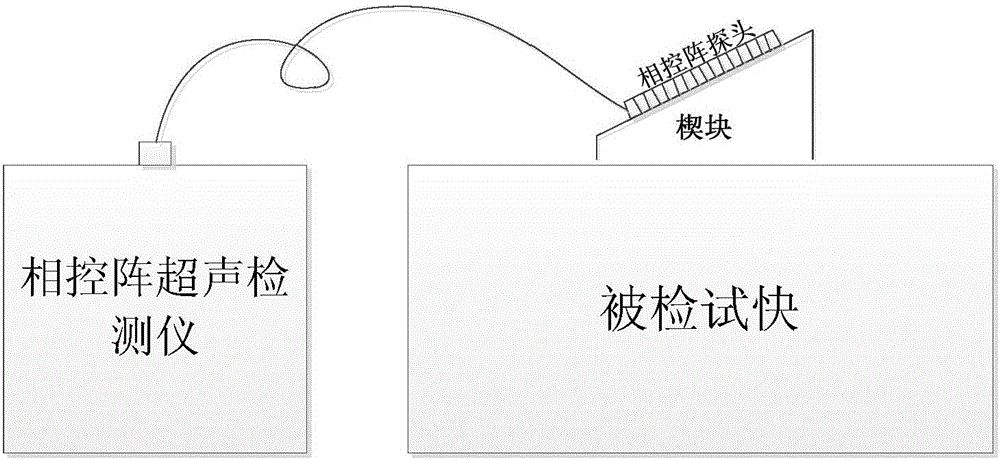

[0037] A defect two-dimensional shape imaging detection method based on multi-mode acoustic beam synthetic aperture focusing, the ultrasonic detection system used is such as figure 1 As shown, it includes a phased array ultrasonic detector, a phased array ultrasonic probe, and a tilted plexiglass wedge. The specific detection and processing steps are as follows:

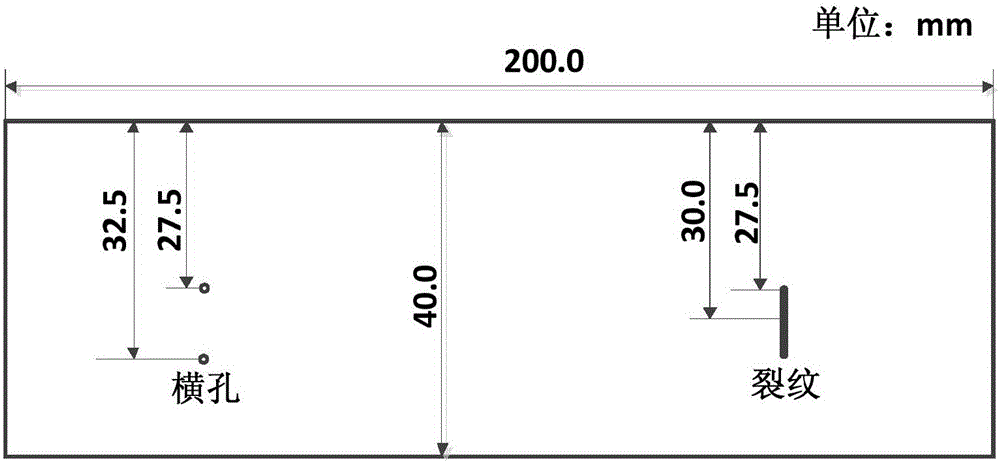

[0038] (a) The tested test block is a carbon steel test block with a thickness of 40mm. The size of the test block is 200mm×200mm×40mm. The test block has a center depth of 30mm and a length of 5mm crack and a depth of 27.5mm and 32.5mm respectively. Holes, such as figure 2 Shown.

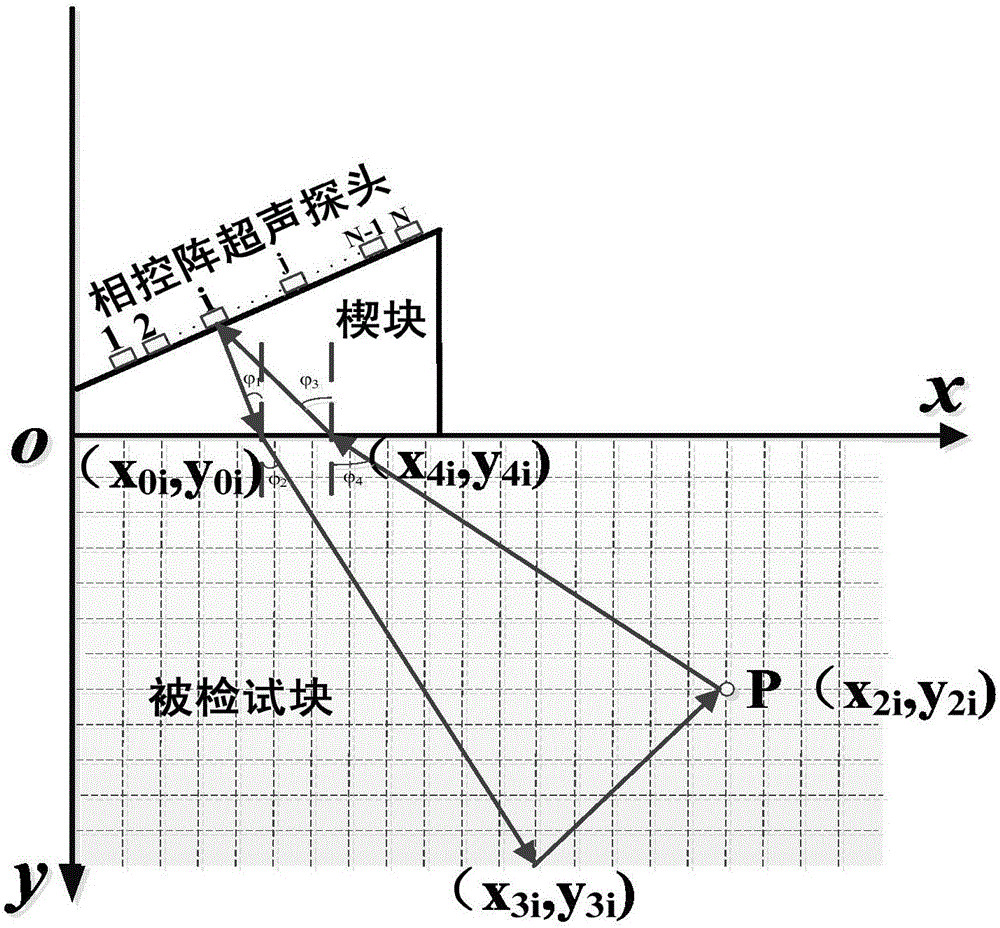

[0039] (b)Using the M2M phased array ultrasonic inspection system, the phased array ultrasonic probe is used with a wedge to test the test block. The number of phased array ultrasonic probes is 32, the center frequency is 5MHz, and 2 array elements are used as 1 excitation aperture, the aperture size is 10mm×1.2mm. The wedge tilt angle is 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com