Method for detecting coal-rock interface by phased-array ultrasonic imaging

An ultrasonic imaging detection and phased array technology, which is used in the analysis of solids using sonic/ultrasonic/infrasonic waves, can solve the problems of many interference signals and unreliable sensor vibration signals, and achieves high interference noise, high speed and high precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

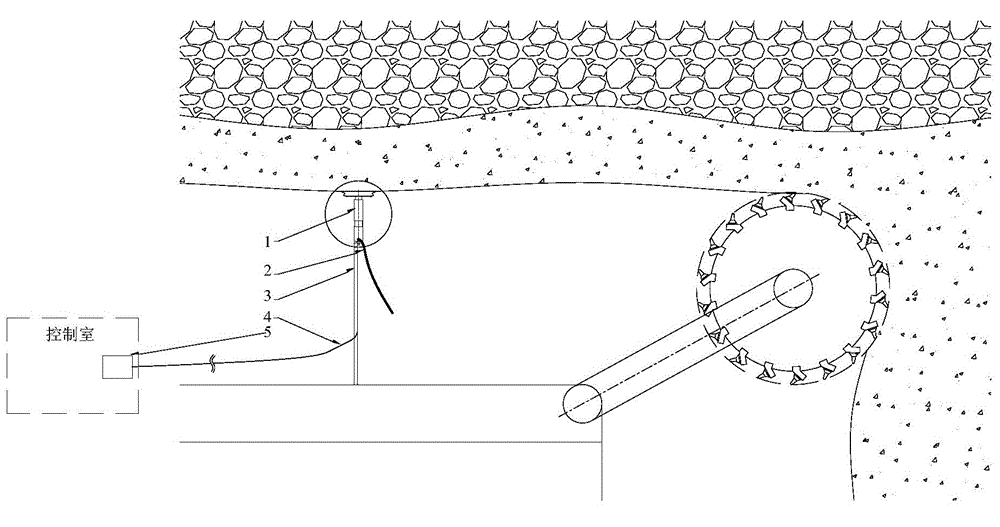

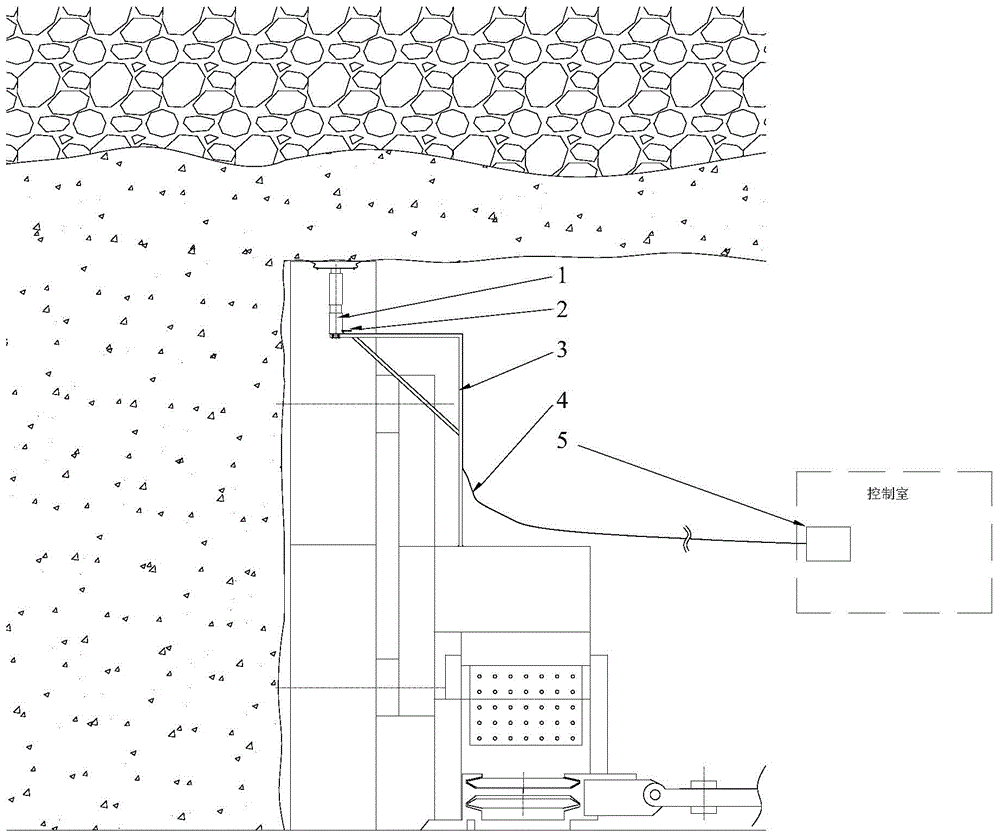

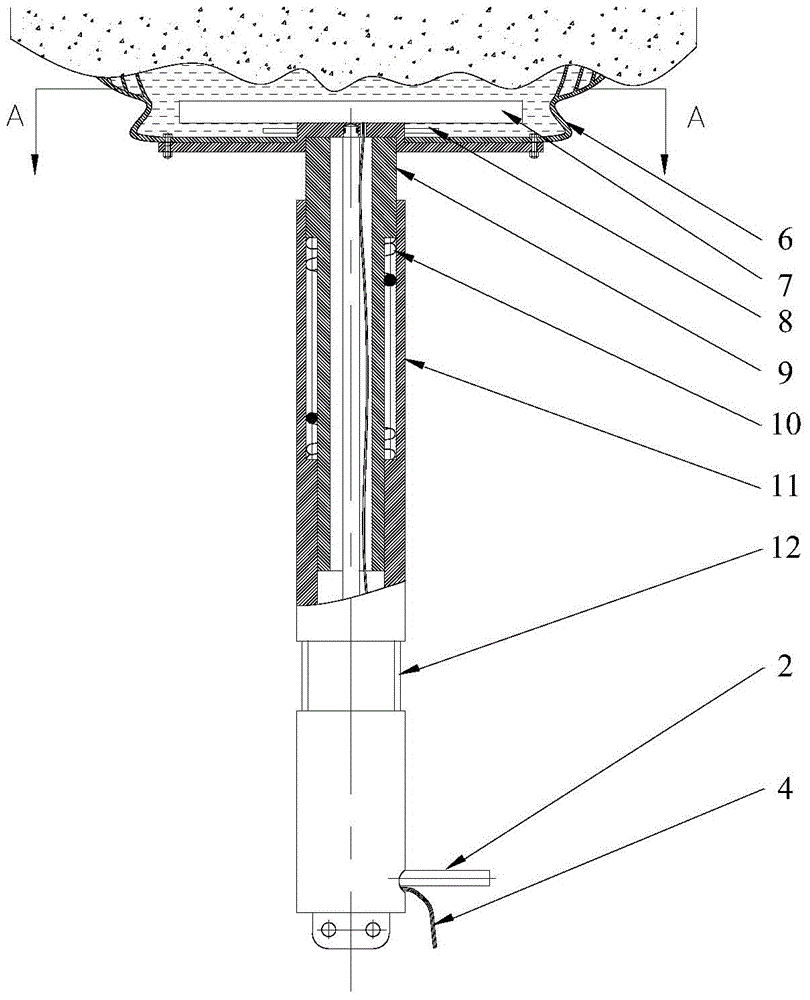

[0044] see figure 1 with figure 2 , the present invention provides a method for detecting coal-rock interface using phased array ultrasonic imaging for detecting coal seam thickness at coal mining sites, the method for detecting coal-rock interface using phased array ultrasonic imaging The coal-rock interface system is installed on the shearer, which is realized by driving it forward. The system for detecting the coal-rock interface is composed of an ultrasonic phased array transducer 7, a coupling device 1, a post-processing imaging device 5 and a supporting device 3. see image 3 with Figure 4 , the ultrasonic phased array transducer 7 is located in the coupling device 1 and connected to the post-processing imaging device 5 . The post-processing imaging device 5 is located in the control room, and is connected with the ultrasonic phased array transducer 7 through the wire 4 . The echo signal received by the ultrasonic phased array transducer 7 is transmitted to the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com