Calculation method of sound field distribution of phased array ultrasonic probe in flaw detection in multilayer medium

A technology of ultrasonic probe and multi-layer medium, applied in the direction of processing the response signal of detection, to achieve the effect of assisting process design, defect evaluation, and fast calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

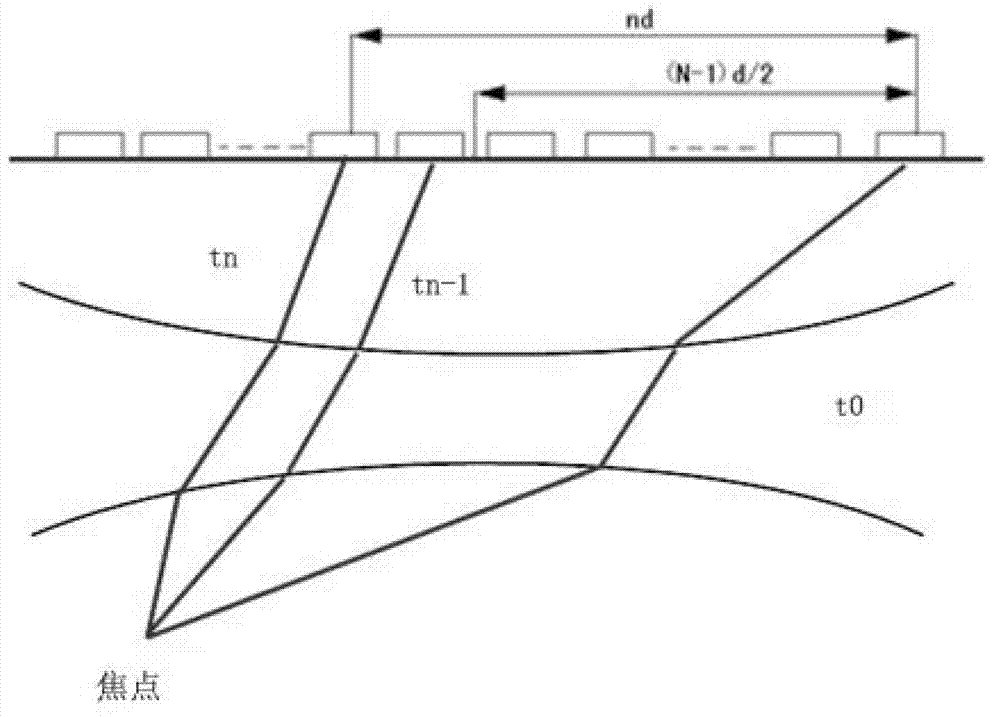

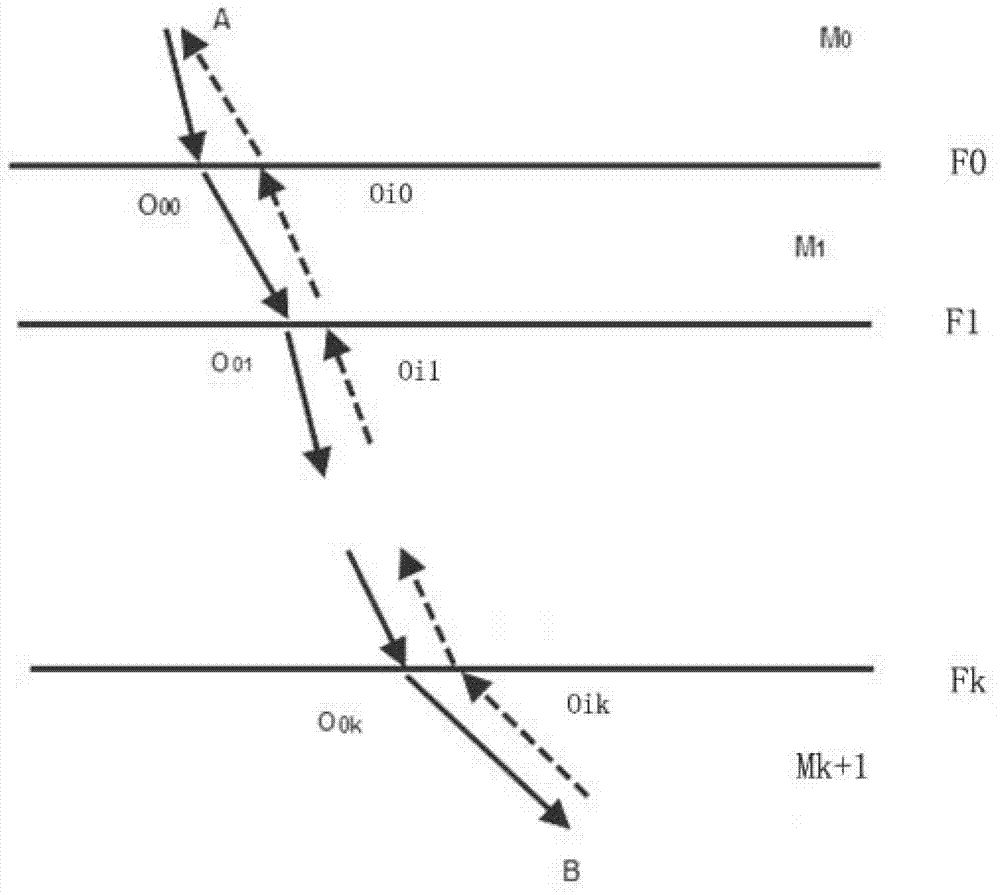

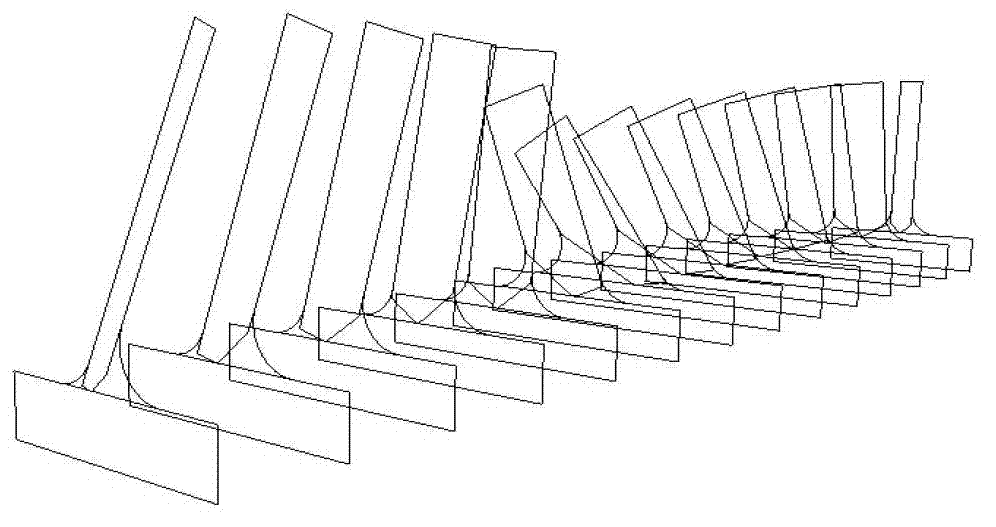

[0038] Implementation case: The welding seam connecting the turbine runner blade with the upper crown and lower ring is prone to fatigue cracks due to alternating stress during service. The thickness of the weld seam of the runner changes continuously from the water inlet side to the water outlet side. The phased array detection process design usually divides the weld seam into a series of detection areas with small thickness differences, and independently designs the parameters of each area, such as image 3 shown. The acoustic beam propagation medium composed of phased array probe wedges and runner welds can also be regarded as a multi-layer medium with large acoustic differences.

[0039]This algorithm is used to calculate the sound field distribution of the phased array probe in the wheel structure. The parameters of the phased array probe are frequency 2.25MHz, the size of a single chip is 0.5*10mm, and the gap between chips is 0.1mm. When the point source is discrete, ea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com