Phased array ultrasonic testing method based on improved dynamic depth focusing

A technology of dynamic depth focusing and ultrasonic detection, which is applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids and process detection response signals, etc. It can solve the distortion of phased array ultrasonic synthesis signal and affect the spatial resolution and Problems such as contrast, sound beam focusing and sound beam synthesis are difficult to achieve the effects of reducing hardware system errors, improving phased array ultrasonic imaging quality, and improving detection resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] Example: This embodiment proposes a phased array ultrasonic detection method based on improved dynamic depth focusing, which includes the following steps:

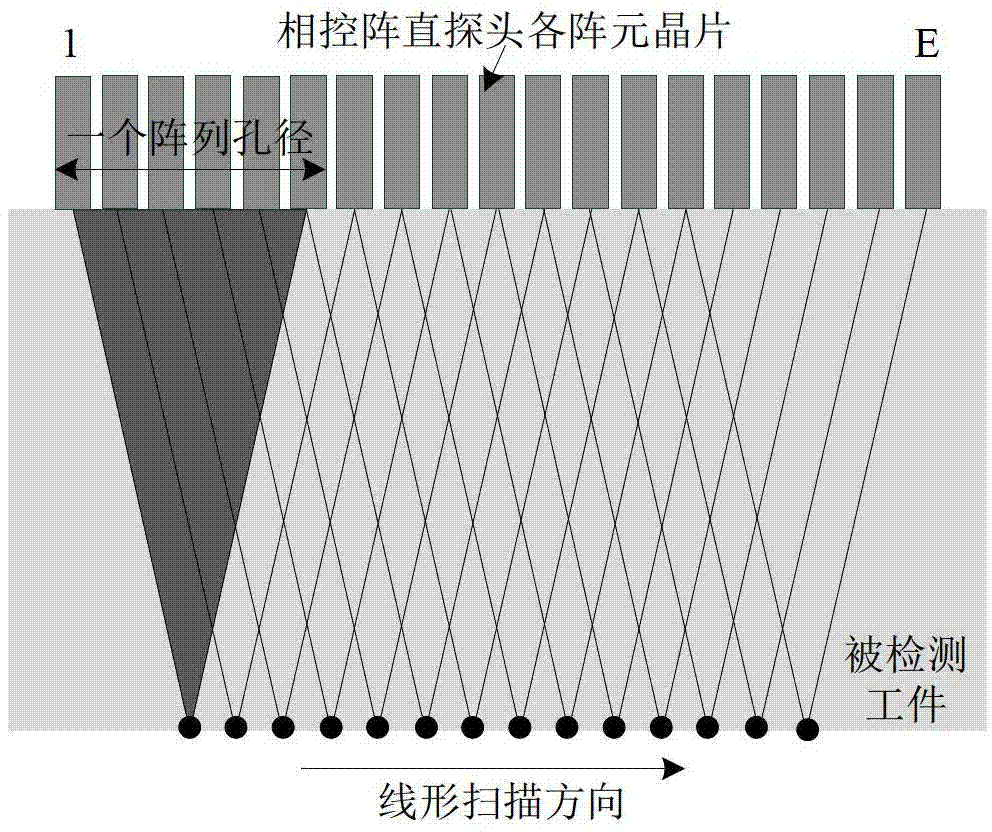

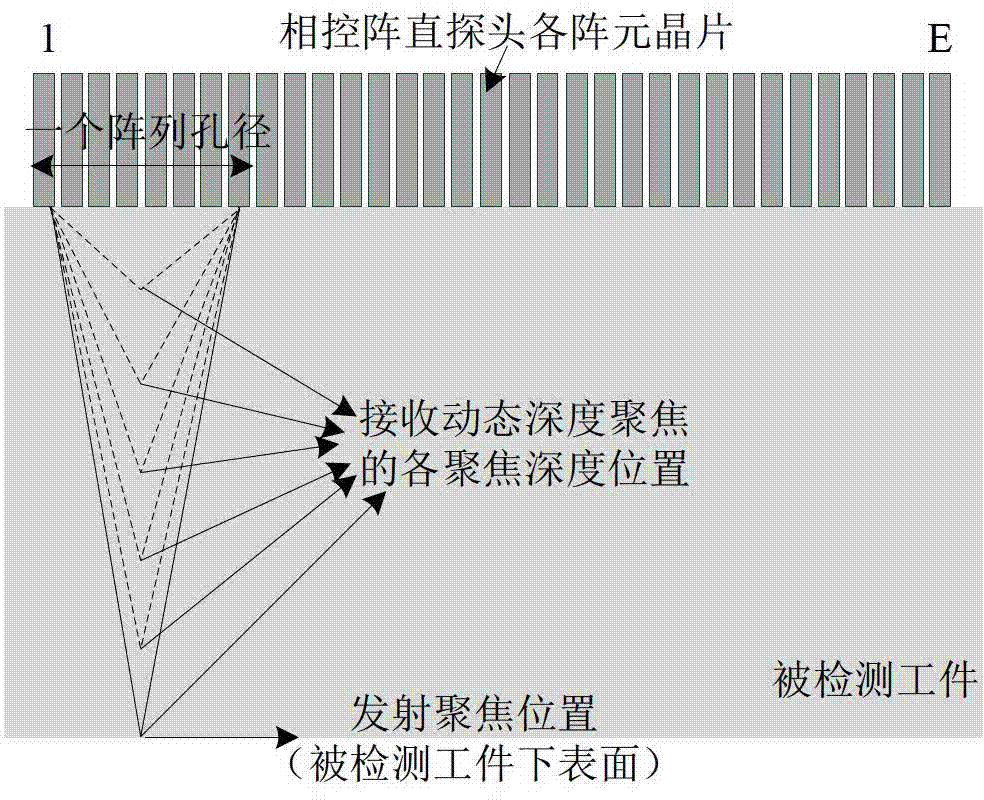

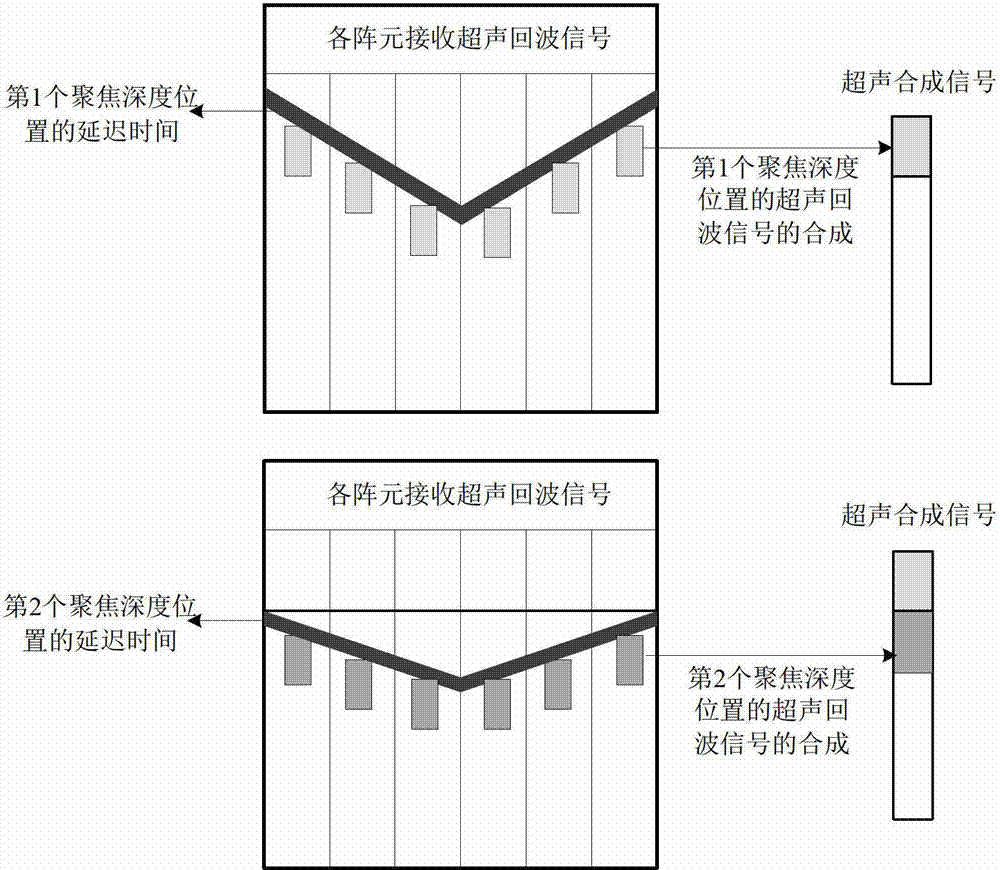

[0043] Step 1. Take a phased array one-dimensional linear straight probe containing E (32) array element chips as an example, and use the phased array linear electronic scanning method to transmit ultrasonic waves. First, take No. 1~E / 4 (1 ~No.8) array elements, these E / 4 array elements form the first array aperture, and calculate the delay time of each array element in the array aperture, so that the ultrasonic beam emitted by each array element is vertically focused and incident on the detected workpiece lower surface. Then, select No. 2~(E / 4+1) (No. 2~9), No. 3~(E / 4+2) (No. 3~10), No. 4~(E / 4+2) in the phased array straight probe respectively 4+3) (No. 4~11)...(3E / 4+1)~E (No. 25~32) array elements form different array apertures, then the probes of E array element chips contain a total of 3E / 4+ 1 (25) array ape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com