Railway axle phased array ultrasonic flaw detection self-adaptive scanning device

A technology of ultrasonic flaw detection and scanning device, which is applied in the direction of measuring device, material analysis using sound wave/ultrasonic wave/infrasonic wave, instrument, etc. It can solve the problems of economic loss of flaw detection, damage of probe and fixture, low detection efficiency, etc., and achieve guarantee Safety and stability, reducing friction, and protecting the safety of testing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order for those skilled in the art to better understand the technical solutions provided by the present invention, the following will be described in conjunction with specific embodiments.

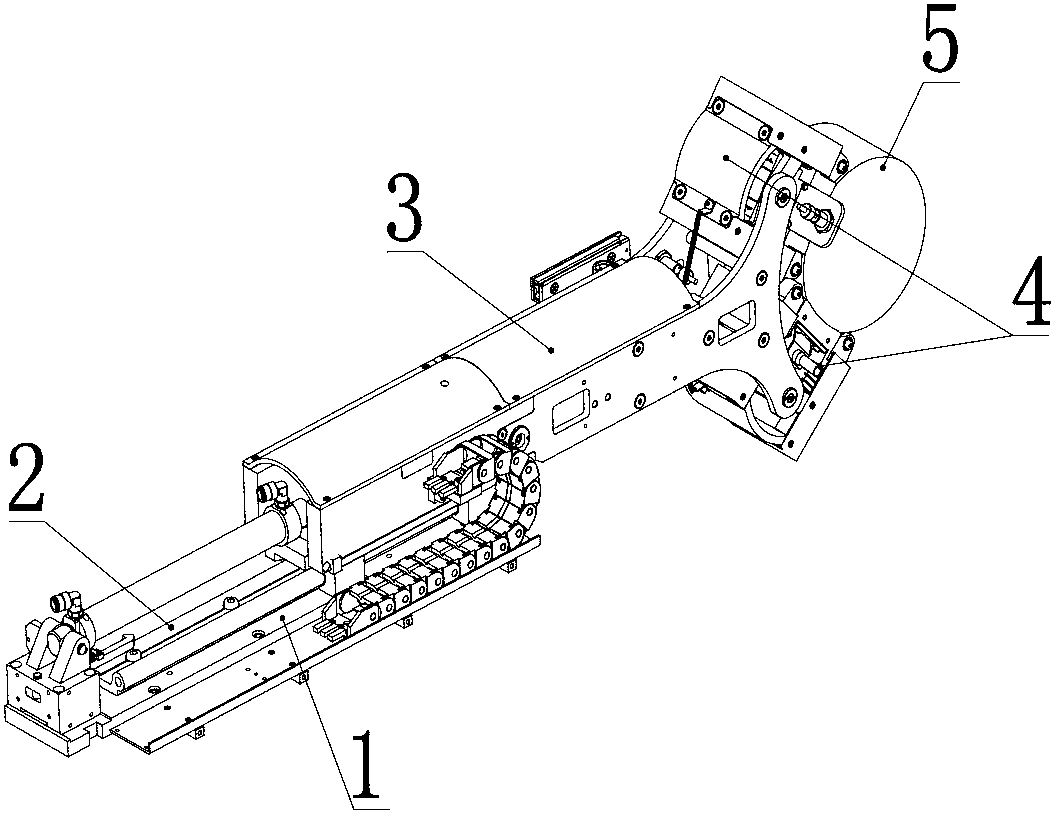

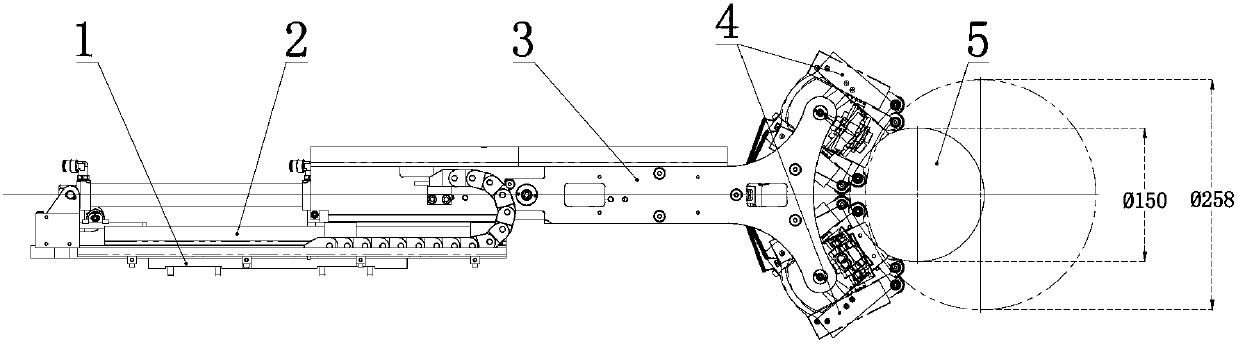

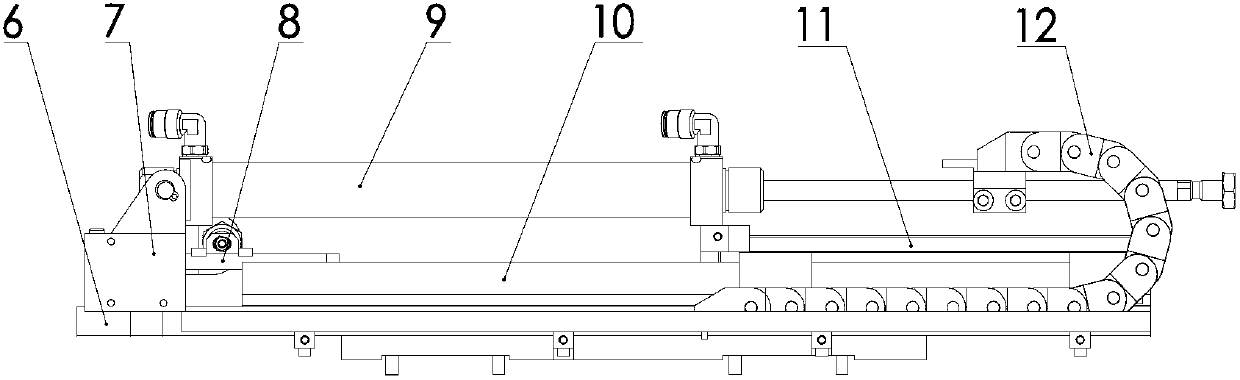

[0015] See Figure 1-Figure 4 , figure 1 It is a schematic diagram of the structure of the railway axle phased array ultrasonic flaw detection adaptive scanning device in the embodiment of the present invention when it is working, and the axle diameter of the axle in the figure is φ150mm; figure 2 It is a structural schematic diagram of the railway axle phased array ultrasonic flaw detection adaptive scanning device in the embodiment of the present invention when it is working, and the axle diameter of the dashed line axle in the figure is φ250mm; image 3 It is a structural schematic diagram of the telescopic drive device in the self-adaptive scanning device for phased array ultrasonic flaw detection of railway axles in the embodiment of the present invention; Figure 4 It is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com