Method and apparatus for measuring thickness of intermediate layer of three-layer composite plate

A composite board and intermediate layer technology, applied in the direction of measuring devices, using ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems of poor accuracy, difficulty in detection, and difficulty in direct measurement, so as to improve measurement efficiency, facilitate detection and operation, and calculate high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

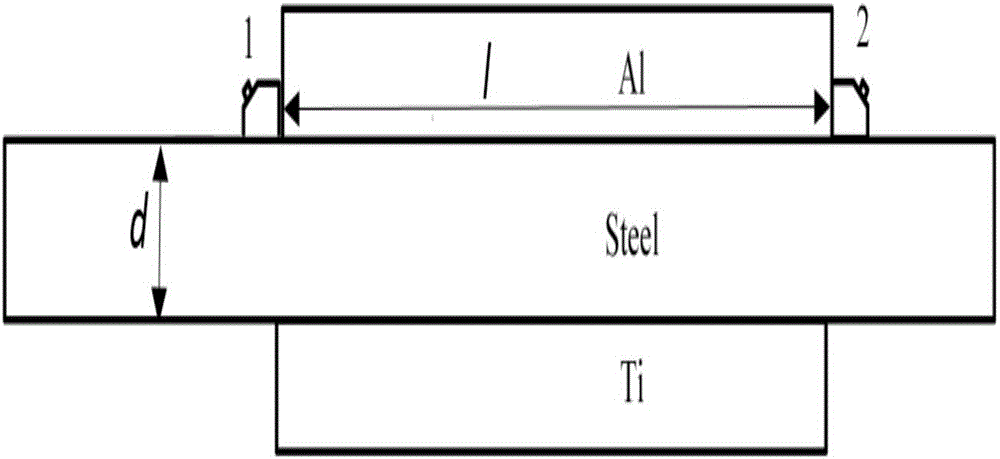

[0052] One of the purposes of the present disclosure is to provide a simple and accurate detection method for the thickness of the middle layer of a three-layer composite board. next Figure 1-5 Describe the content of the disclosed method.

[0053] Step (1), obtain the frequency-thickness product of the tested three-layer composite board

[0054] The frequency-thickness product of the three-layer composite board is only related to the material of the three-layer board. The frequency-thickness product of the tested three-layer composite board can be obtained through simulation. The following steps can be used specifically:

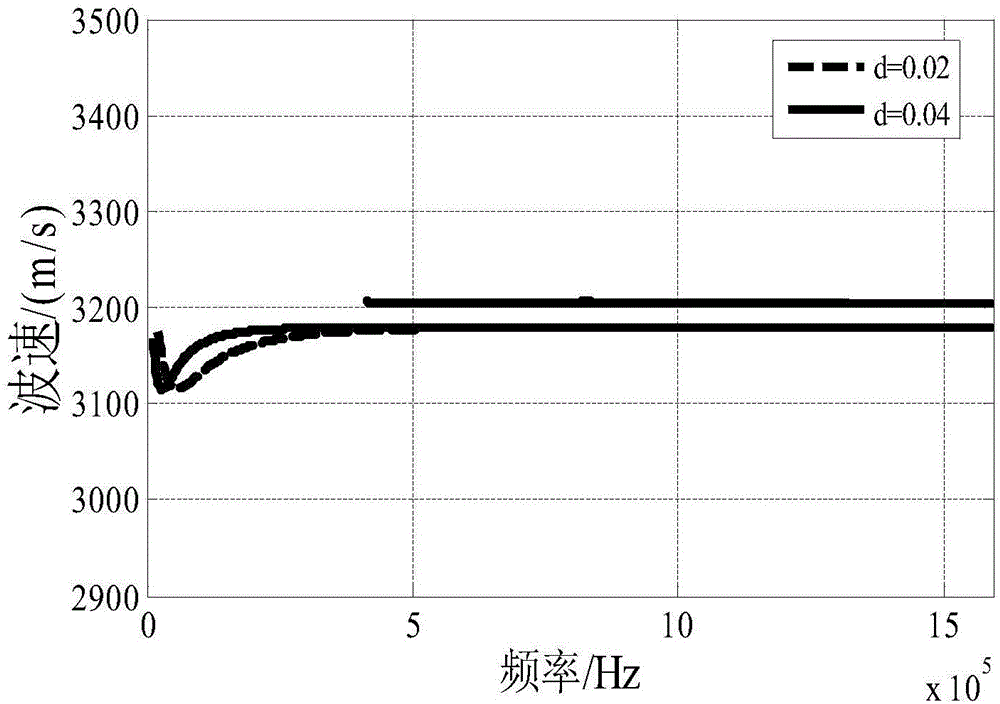

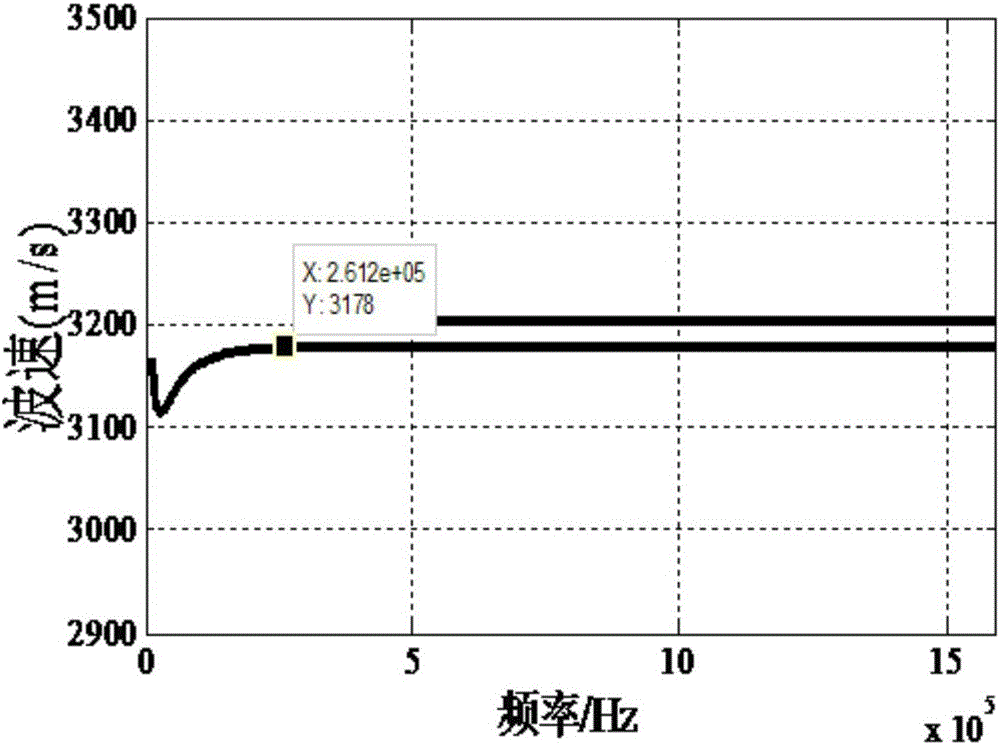

[0055] S101. Obtain the phase velocity dispersion curve by simulating the three-layer composite board having the same material as the three-layer composite board to be tested;

[0056] S102. Find the phase velocity stable corner frequency from the phase velocity dispersion curve, and obtain the frequency-thickness product of the tested three-layer composit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com