Electromagnetic ultrasonic thickness measurement method and device

An ultrasonic and thickness measurement technology, applied in the field of measurement, can solve problems such as the need to improve accuracy, and achieve the effect of highlighting substantive features, convenient implementation and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

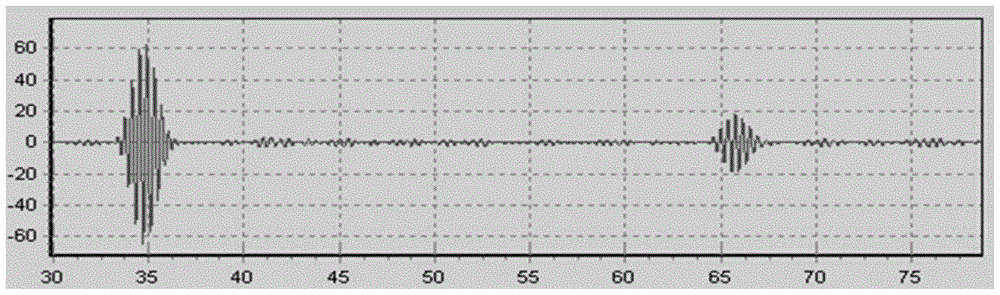

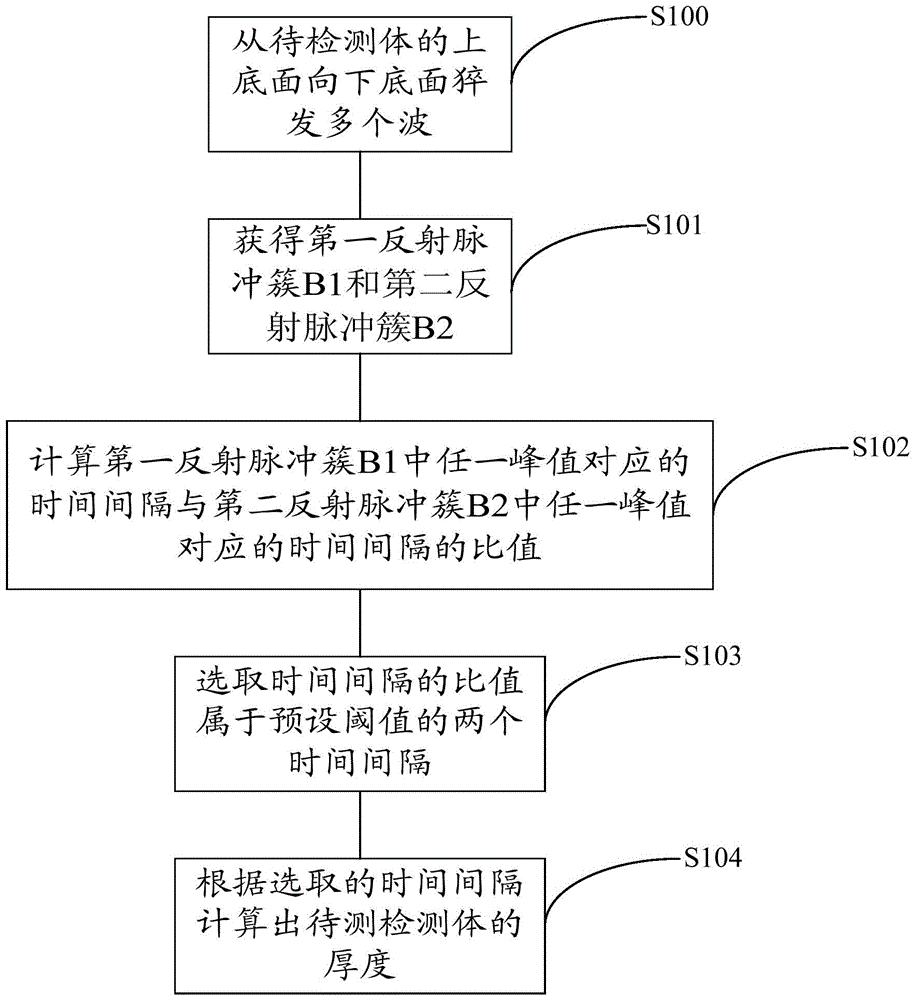

[0042] It is found through research that if the thickness H is calculated directly from the time t from the burst wave to the detection of the first lower bottom echo cluster, that is, H=Vt / 2, where V is the transmission speed of the electromagnetic ultrasonic wave in the object to be detected, It can be found by looking up the manual or calculating by measuring. Due to the different environmental conditions of the burst wave, the internal defects that may exist in the object to be tested, etc., the thickness measurement results have a large deviation from the actual thickness. Calculation, namely H=V(t 2 -t 1 ) / 2, where t 2 -t 1 is the time difference between adjacent bottom-surface echo clusters (within the same trigger period).

[0043] The inventor found through research that although the calculation of the thickness based on the time difference of the adjacent bottom surface echo clusters can improve the calculation accuracy of the thickness of the object to be detect...

Embodiment 2

[0062] It is found through research that if the thickness H is calculated directly from the time t from the burst wave to the detection of the first lower bottom echo cluster, that is, H=Vt / 2, where V is the transmission speed of the electromagnetic ultrasonic wave in the object to be detected, It can be obtained by looking up the manual or through measurement and calculation. Due to the different environmental conditions of the burst wave and the possible internal defects of the object to be tested, the thickness measurement result has a large deviation from the actual thickness. In order to improve the thickness measurement accuracy, it is mainly based on phase The time difference of the echo cluster adjacent to the bottom surface is used to calculate the thickness, that is, H=V(t 2 -t 1 ) / 2, where t 2 -t 1 is the time difference between adjacent bottom-surface echo clusters (within the same trigger period).

[0063] The inventor found through research that although the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com