Method for detecting T-shaped groove in rotor rim of steam turbine

A steam turbine rotor and slot detection technology, which is used in measuring devices, material analysis using sonic/ultrasonic/infrasonic waves, and solids analysis using sonic/ultrasonic/infrasonic waves, etc. , low detection efficiency and other problems, to achieve the effect of improving detection efficiency, large scanning range, and realizing positioning and quantification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

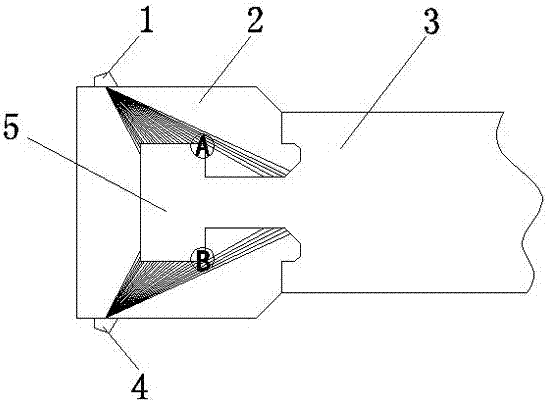

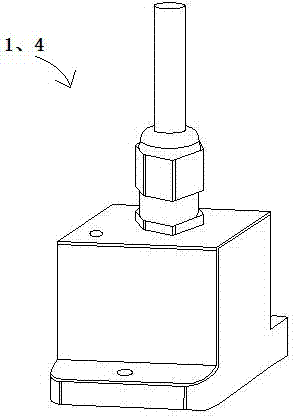

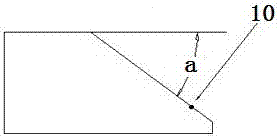

[0022] The specific embodiment of steam turbine rotor rim T-shaped groove detection method of the present invention is as follows: figure 1 As shown, when the steam turbine rotor is running at high speed, its blades are subjected to a large centrifugal force, and the centrifugal force is transferred to the T-shaped groove of the impeller flange through the T-shaped blade root, so that the T-shaped groove produces stress concentration in the sharp angle A and B areas , due to the harsh operating conditions of the steam turbine rotor, the stress concentration part is prone to stress corrosion cracks and fatigue cracks, so this part is the key detection area. Draw a two-dimensional model diagram of the T-groove of the impeller flange according to the structural size of the T-groove of the impeller flange to be inspected, and use the ultrasonic phased array ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com