Ultrasonic detection method of babbit metal bearing

A babbitt alloy and ultrasonic detection technology, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, etc., can solve problems such as low detection efficiency, environmental impact, and long time required to improve detection efficiency and avoid pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

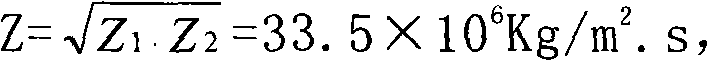

[0012] Babbitt bearings are a combination of different metals. Defects such as pores in the bonding layer and poor bonding cannot be detected by naked eyes or surface flaw detection methods. To detect defects inside the workpiece, only ultrasonic flaw detection methods can be selected. According to the principle of ultrasonic flaw detection, if the propagating ultrasonic wave encounters a defect, an echo signal will be generated and received by the probe, and displayed on the fluorescent screen of the flaw detector. According to the echo signal, information such as the location and equivalent size of the defect can be obtained.

[0013] In ultrasonic testing, the choice of probe and flaw detector is crucial. The flaw detector requires high precision, high sensitivity, low electrical noise, stable waveform signal, easy operation, and can store data such as testing waveforms to track and compare testing results, and understand the changes in the location, size and nature of defec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com