Measuring system for a medium flowing in a process line

A measurement system and pipeline technology, applied in the field of measurement systems, can solve problems such as limited application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

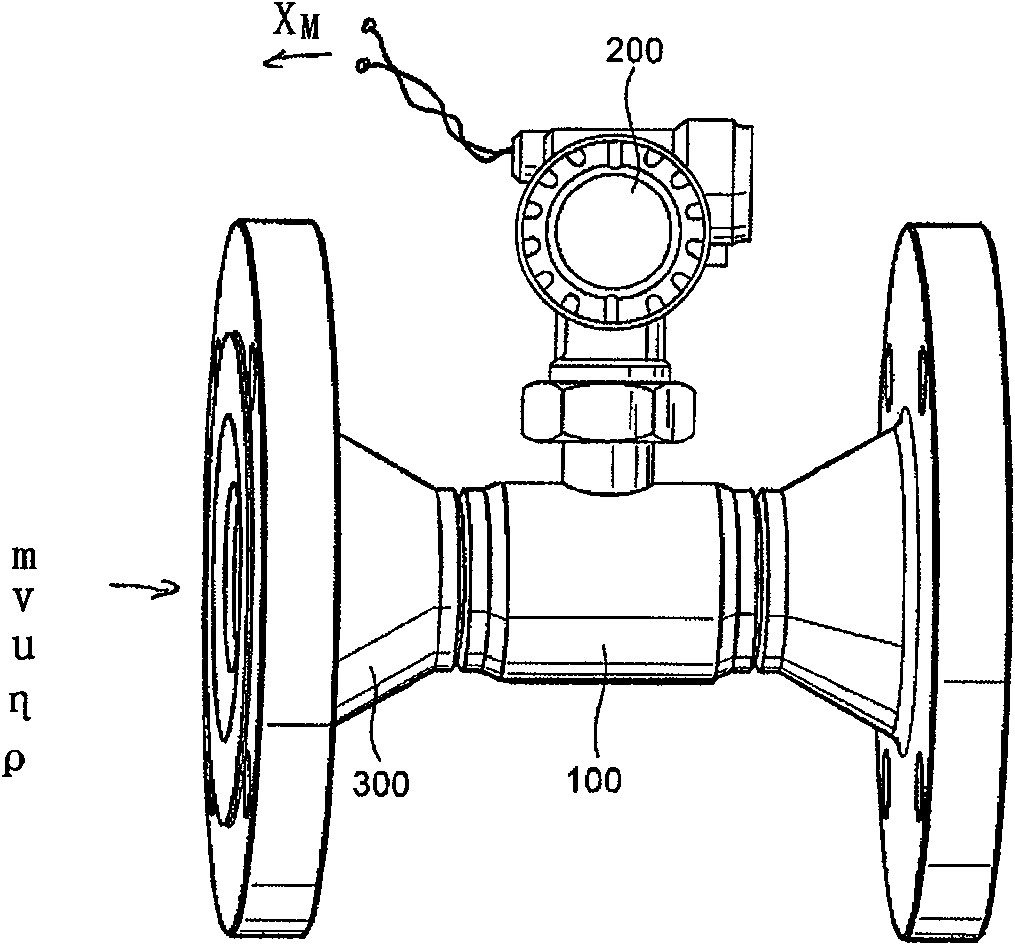

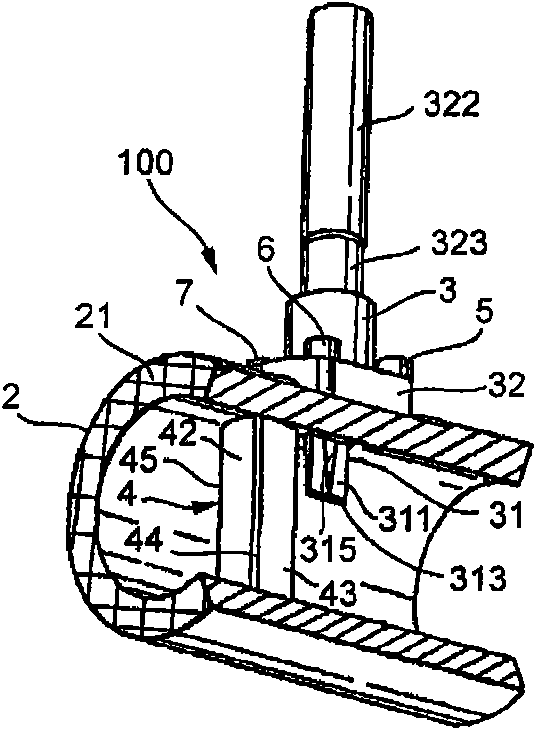

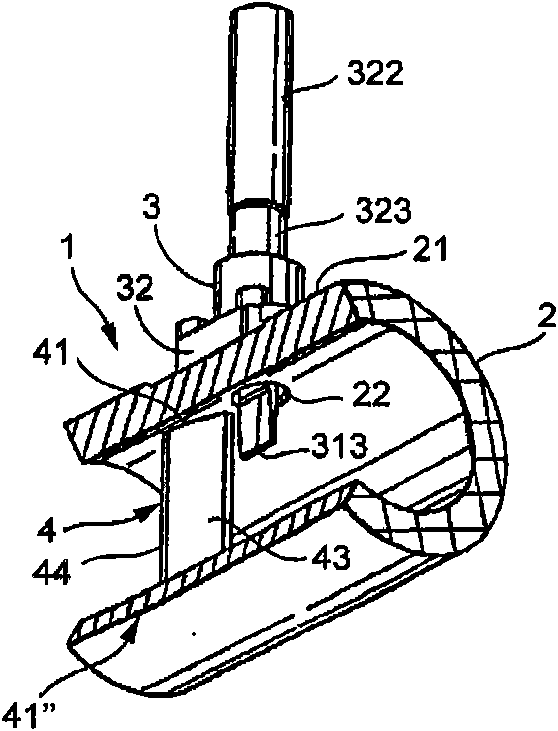

[0121] figure 1 Schematically shows a measuring system, which if required can be assembled modularly, which is suitable for very robust measurement of at least one measured variable of a medium (eg liquid, gas, steam, etc.) flowing in a process line not shown , in particular mass flow m and / or volume flow v and / or flow velocity u and / or other flow parameters, and for mapping this measured variable to at least one corresponding measured value X M . For this purpose, the measuring system includes at least one online measuring device for the flowing medium. The measuring device is formed with a suitable measuring transducer 100 and measuring electronics electrically coupled thereto at least intermittently. The on-line measuring device then comprises a measuring transducer 100 through which the medium to be measured flows during operation, and an electronics housing 200 in which measuring electronics (not described in detail here) are housed in electrical connection with the mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com