Method for measuring deformation of metal cylinders under internal explosion effect and device

A metal cylinder and explosive action technology, applied in the field of explosive mechanics, can solve problems such as the inability to reflect the relationship between the deformation of the metal cylinder and time, the difficulty of protecting shooting equipment, and the lack of experimental conditions, etc., to achieve reliable measurement results and improve gap measurement The effect of precision, accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

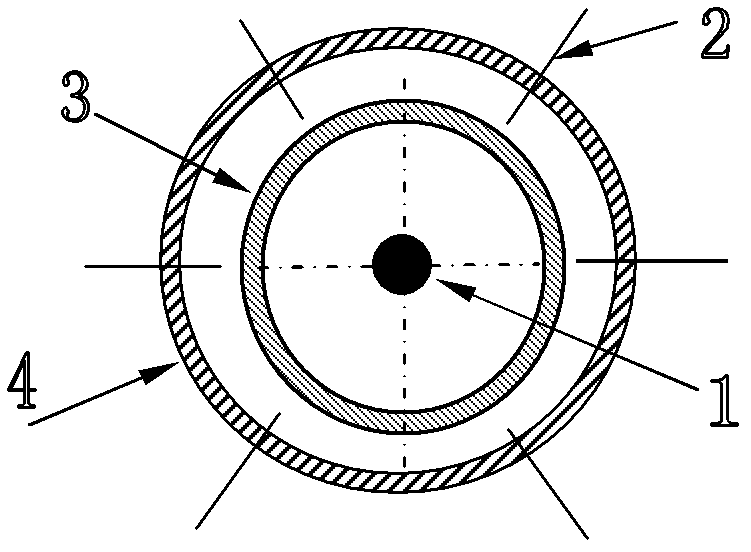

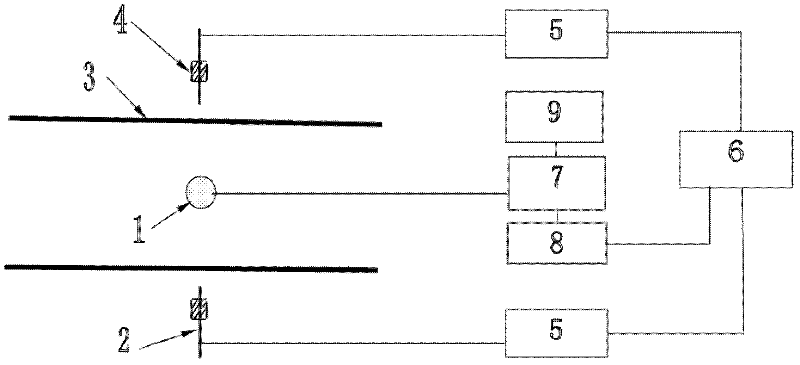

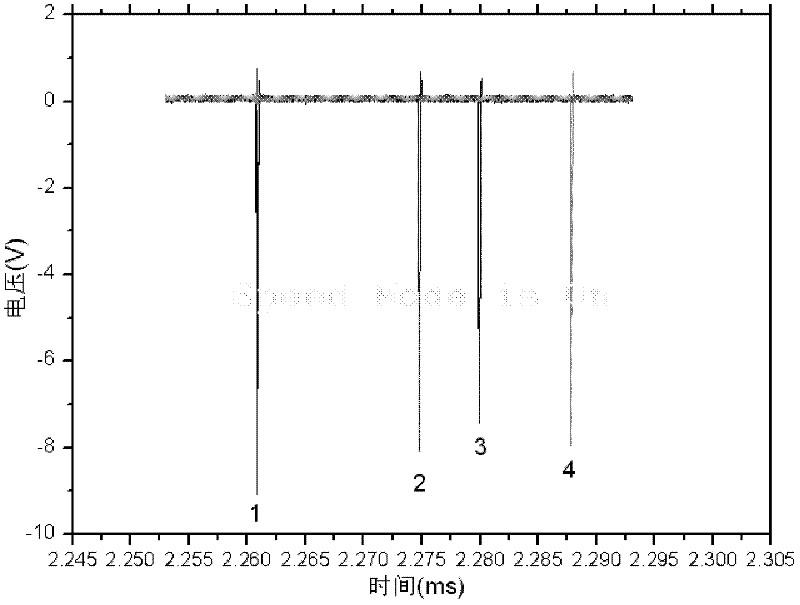

[0035] The material of the metal cylinder 3 is 20# steel, the length is 600mm, the outer diameter is 124mm, and the wall thickness is 12mm; the explosive 1 equivalent to 120gTNT is placed on the inner axis of the metal cylinder 3; a total of 8 electrical probes 2 are set in the experiment: the explosion center 1 electrical probe 2 is set at the place, which is recorded as 1 signal (see Figure 3-A Pulse signal 1); Discharge probes 2 are placed at seven positions of -18°, 18°, 54°, 90°, 126°, 162° and 198° on the positioning ring 4 of the annulus of the detonation center, and the distance between the electric probes 2 The distances between the metal cylinder 3 walls are respectively 0.2mm, 0.5mm, 1.0mm, 1.5mm, 2.0mm, 2.2mm and 2.4mm, which are respectively recorded as 2, 3, 4, 5, 6, 7 and 8 signals (2 , 3, 4, 5, 6 and 7 signals see Figure 3-A and Figure 3-B The pulse signals 2, 3, 4, 5, 6 and 7, and the 8-way signal are not because the probe here is not in contact with the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com