Method of Measuring Temperature Using Bragg Grating Array

A Bragg grating and temperature measurement technology, which is applied in the application of thermometers, thermometers, measuring devices, etc., can solve the problems of low sensitivity to geometric complexity and the inability to realize temperature distribution, and achieve flexible design and manufacturing, small errors, and space The effect of taking up less

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This embodiment includes the following steps:

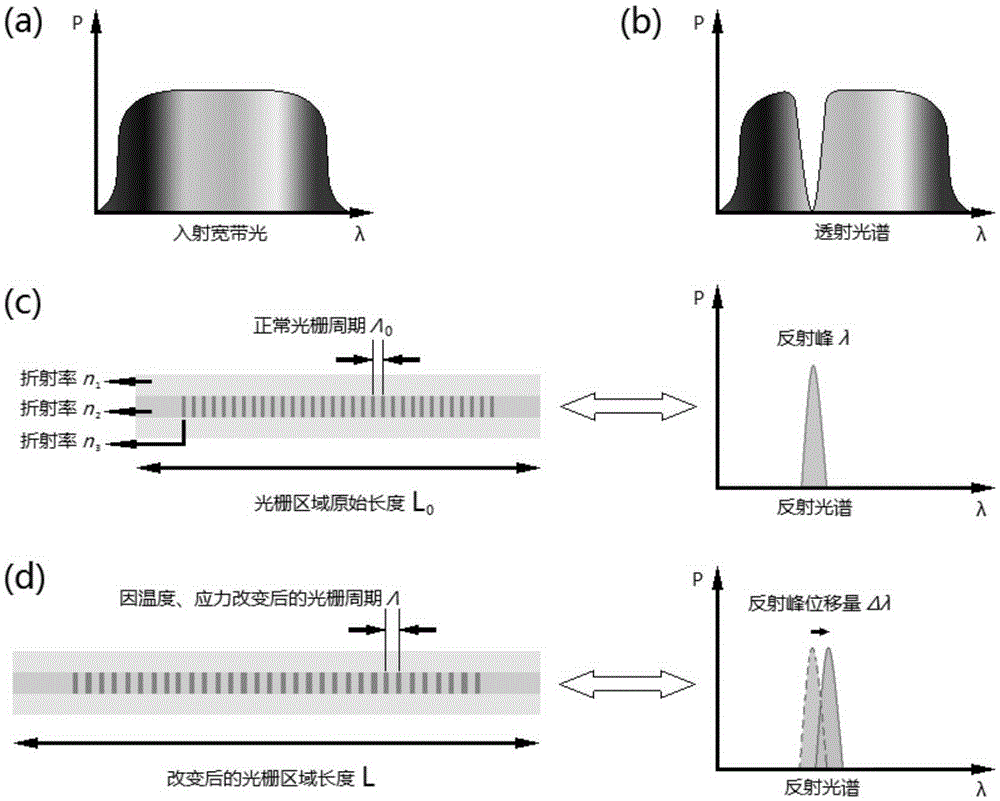

[0044] Step 1. Determine the structure of the temperature measuring device 4 according to the geometric structure of the object to be measured and the temperature measuring point. A number of Bragg gratings are evenly arranged in the temperature measuring device 4. The temperature measuring device 4 fits the temperature measuring point and introduces A beam of broadband input light 3;

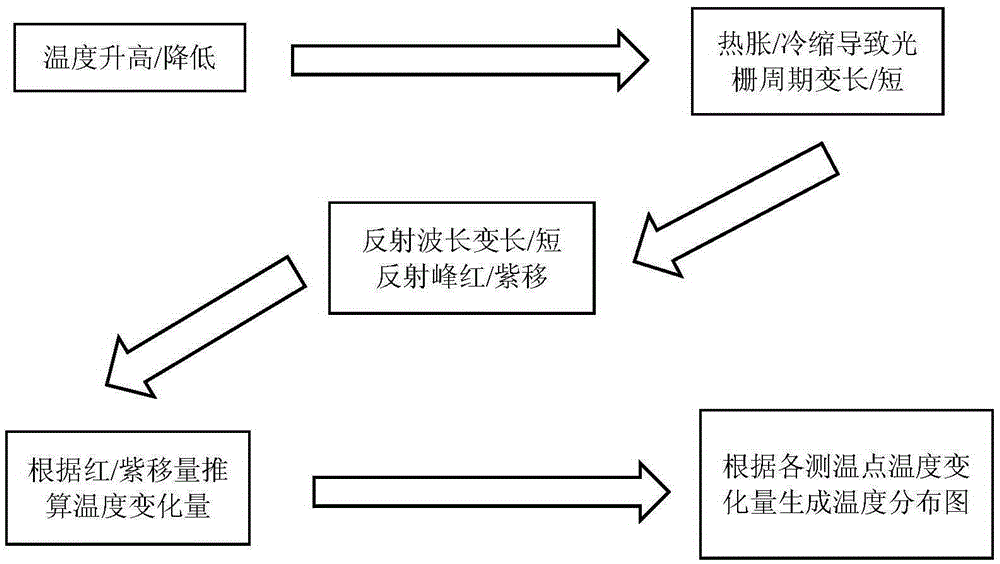

[0045] Step 2. Before the temperature changes, the broadband input light 3 is incident on each Bragg grating 2, and after passing through each Bragg grating 2, the light of the reflection wavelength corresponding to each Bragg grating 2 is reflected back, and the reflected light forms a reference output spectrum; After the temperature changes, the broadband input light 3 is incident on each Bragg grating 2, and after being reflected by each Bragg grating 2, the reflected light forms a changed output spectrum;

[0046] Step 3, comparing the...

Embodiment 2

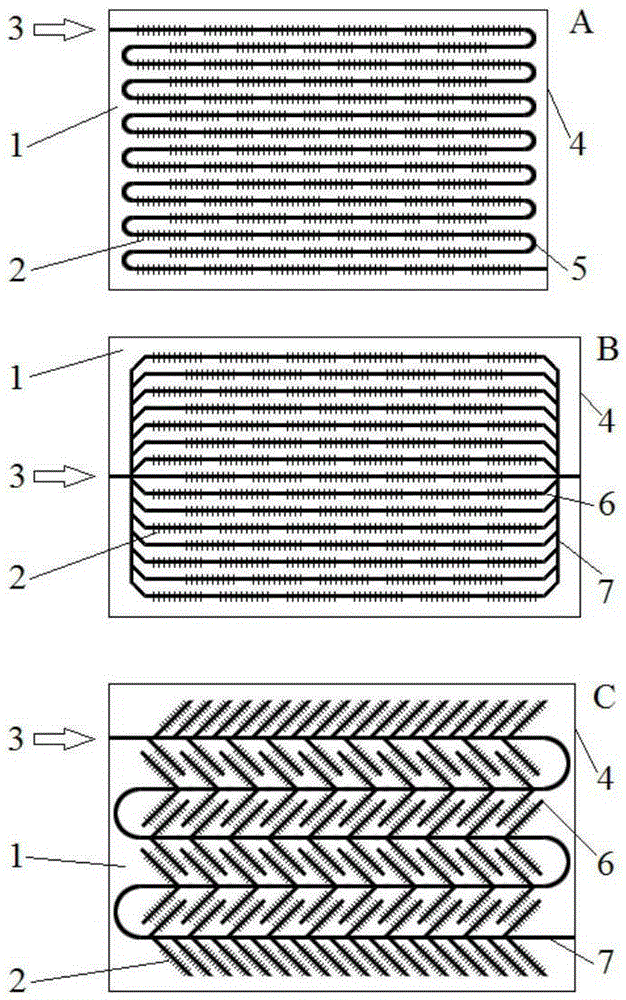

[0062] Such as figure 2 As shown, this embodiment is a temperature measuring device 4 applied to Embodiment 1, including: a chip substrate 1, a number of Bragg gratings 2 arranged in the chip substrate 1 and covering the temperature measurement points of the object to be measured, and broadband input light 3 ,in:

[0063] The arrangement of Bragg gratings 2 is series A, parallel B or series-parallel hybrid C, where:

[0064] The series type A means that all the Bragg gratings 2 in the substrate of the temperature measuring chip are sequentially connected by a waveguide 5 . The incident route of the broadband input light 3 is: sequentially incident on each Bragg grating 2 along the waveguide 5;

[0065] Parallel type B means that each Bragg grating 2 in the substrate of the temperature measuring chip is connected to the trunk waveguide 7 by a branch waveguide 6 . The incident route of the broadband input light 3 is: traveling along the trunk waveguide 7 and splitting the be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com