Device and method of guide rail straightness measuring

A technology of straightness and guide rail, applied in the direction of measuring devices, instruments, etc., can solve the problems of complex implementation, high cost, and difficulty in implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

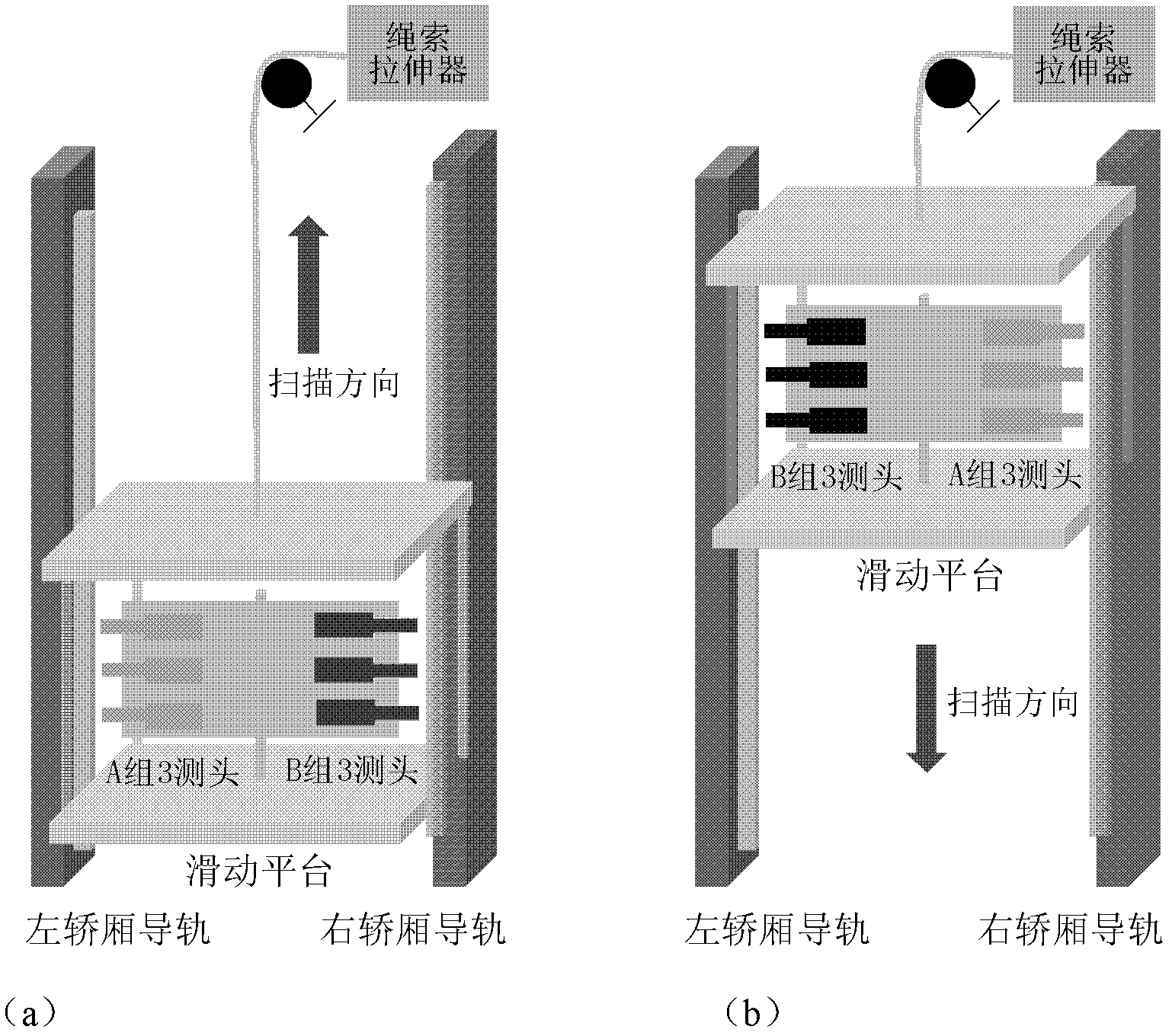

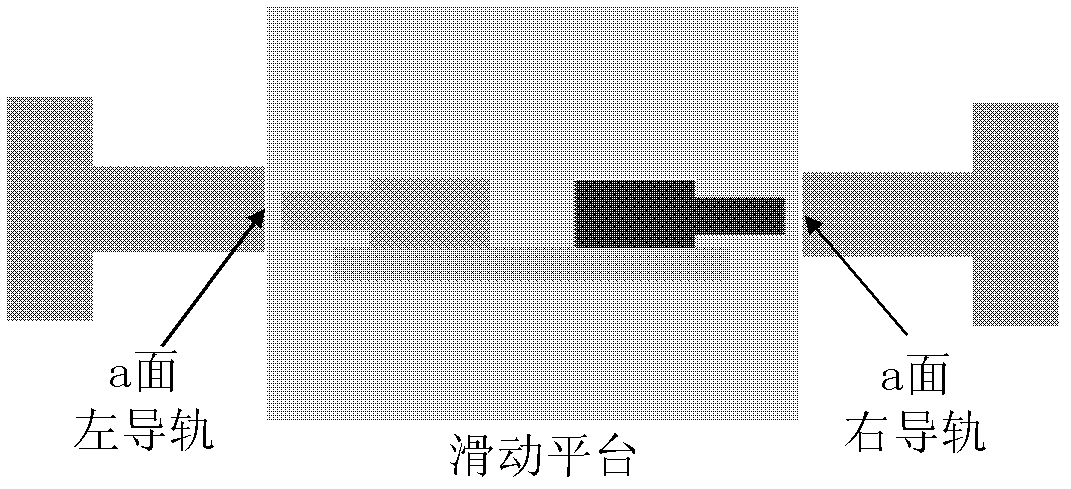

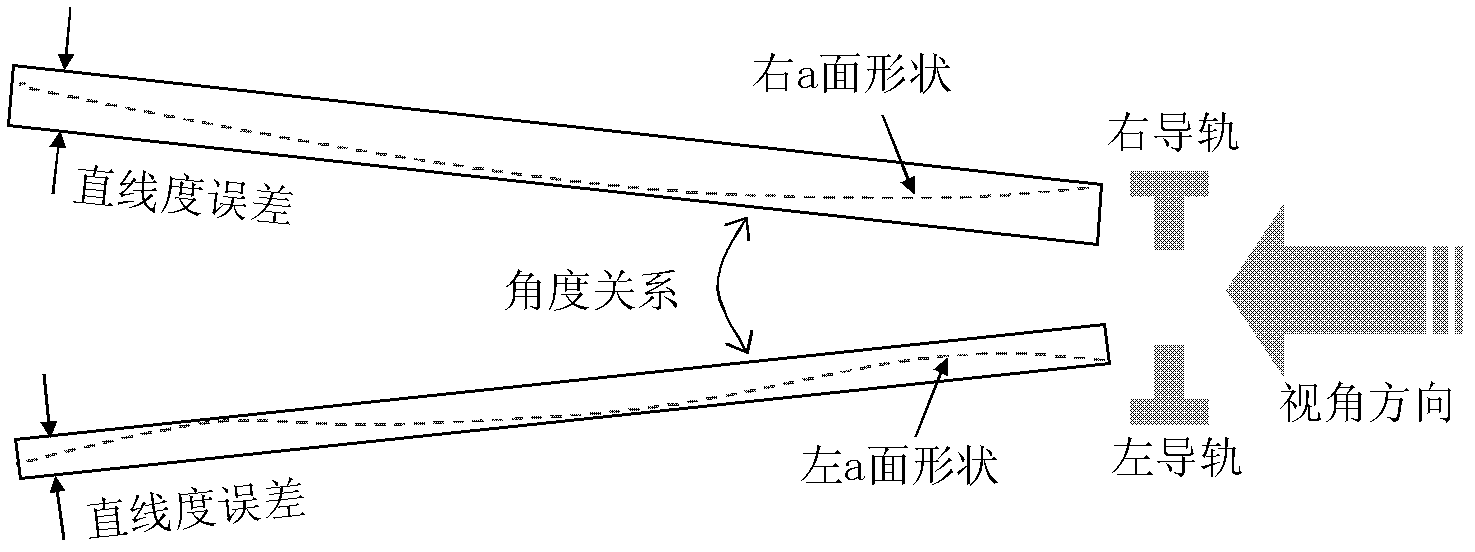

[0030] see figure 1 As shown, the described guide rail straightness measuring device includes:

[0031] The measuring device components include six high-precision displacement sensors and corresponding data acquisition systems and data storage, 1 DC24V power supply, 2 displacement sensor mounting arms and 1 displacement sensor mounting arm base.

[0032] Three displacement sensors are installed on each displacement sensor mounting arm. The distance between the three displacement sensors is roughly equal, and the sensor test surface is basically on the same plane. The two components will not be assembled before the end of this measurement; The two installation arms of the displacement sensor are installed on the base of the displacement sensor installation arm. The base is placed on the sliding platform, and the installation position of the installation arm is adjusted according to the distance between the two guide rails to ensure the distance between the displacement sensor a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com