Measuring device and method for pulsed ion beam cross section image

A pulsed ion beam and cross-sectional image technology, applied in the field of accelerators, can solve problems such as high repetition times, poor cross-sectional image accuracy, and high ion beam current intensity, and achieve the effects of easy preparation, easy purchase, and simple equipment and materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

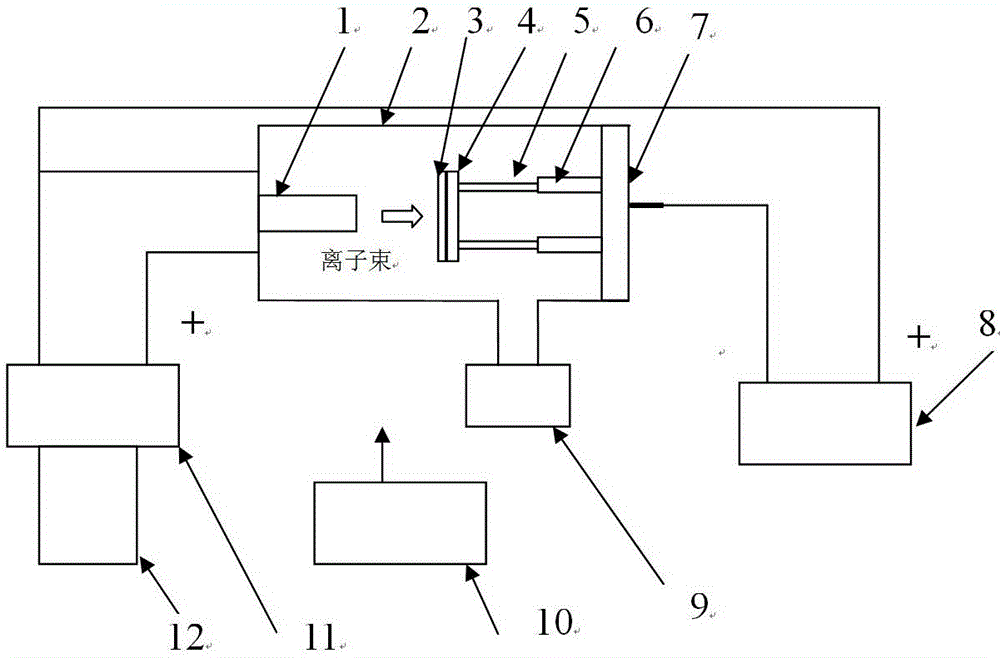

[0023] figure 1 It is a structural schematic diagram of the present invention, in figure 1 Among them, the measuring device of the pulsed ion beam section image of the present invention includes 1. ion source, 2. quartz glass tube, 3. imaging plate, 4. aluminum liner, 5. adjustable pitch screw, 6. adjustable pitch nut, 7. Stainless steel flange, 8. Adjustable acceleration power supply, 9. Vacuum unit, 10. Imaging analyzer, 11. Ion source pulse power supply, 12. Isolation transformer.

[0024] An aluminum liner 4 is set at the target position of the measurement device for the pulsed ion beam cross-sectional image, and the imaging plate 3 is fixed on the aluminum liner 4, and the plate surface is perpendicular to the running direction of the pulsed ion beam; open and adjust the high voltage value of the accelerating power supply 8 to 30kV; the vacuum in the quartz glass tube 2 in the measuring device is pumped to 5×10 by the vacuum unit 9 -4 Pa, adjust the output pulse of the ...

Embodiment 2

[0026] The structure of this embodiment is the same as that of Embodiment 1, and the implementation process is the same, the difference is: adjust the high voltage value of the accelerating power supply 8 to 120kV; set the output pulse repetition frequency of the ion source pulse power supply 10 to 0.1Hz; 10 Start timing, and the measurement time is 20s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com