Method capable of accurately measuring phase delay quantity of wave plate

A wave plate phase and precise measurement technology, applied in the direction of testing optical performance, etc., can solve the problems of difficulty in accurately extracting peak wavelength, affecting measurement results, adjustment errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

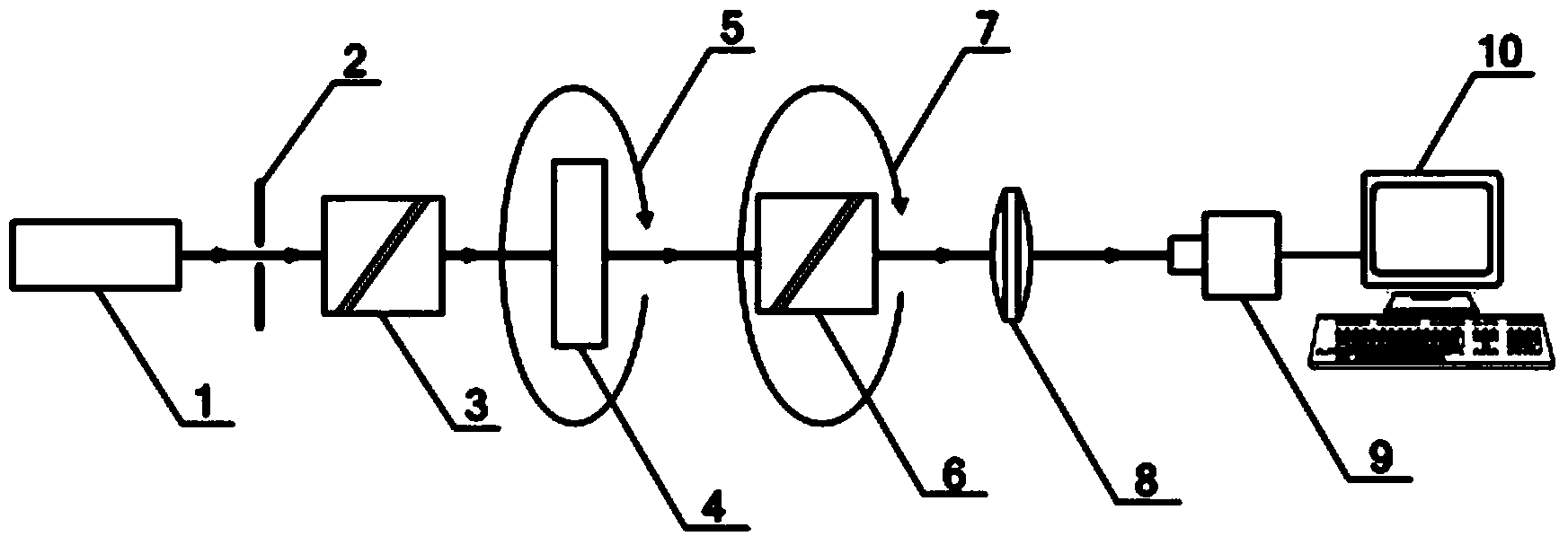

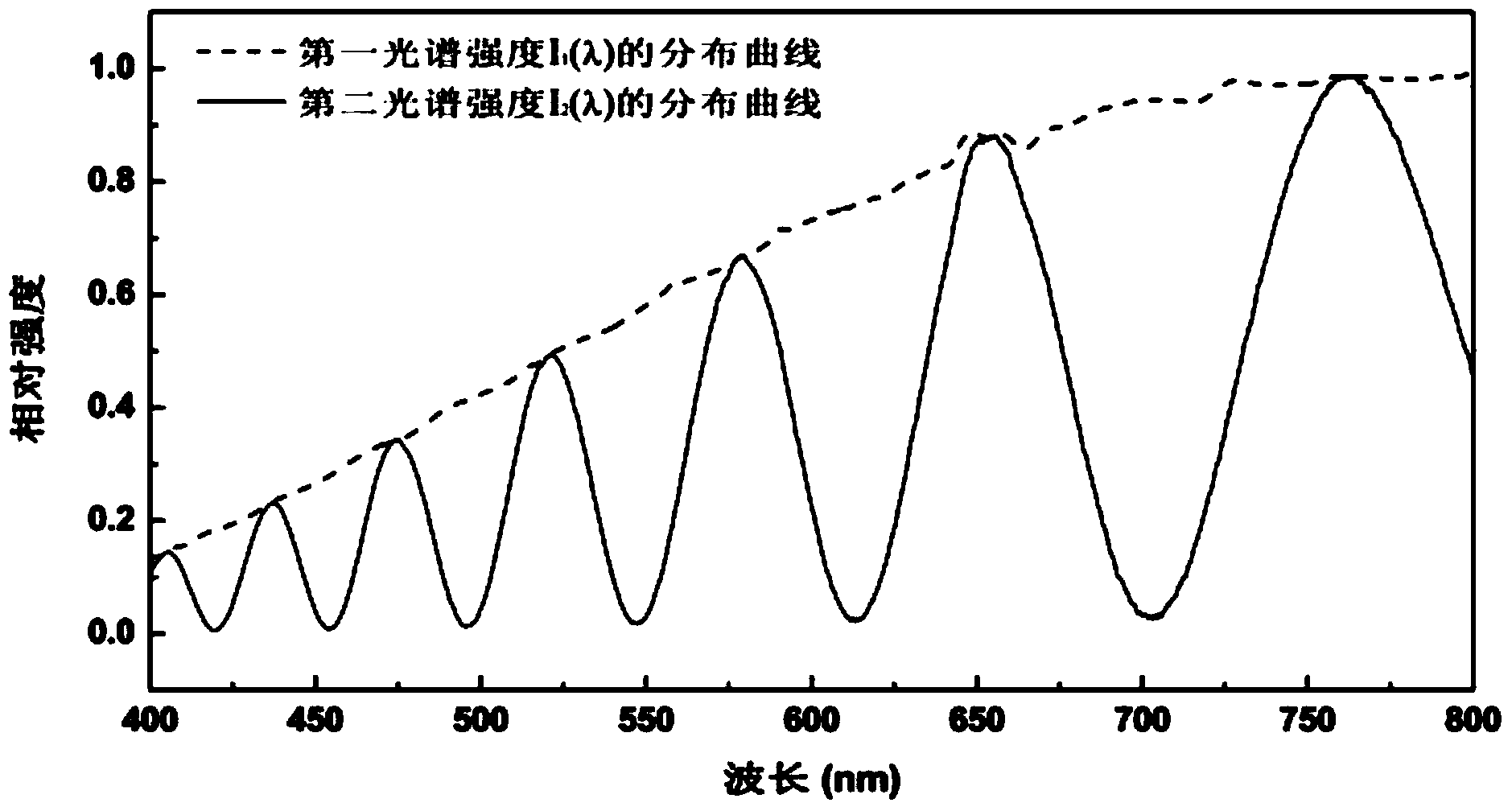

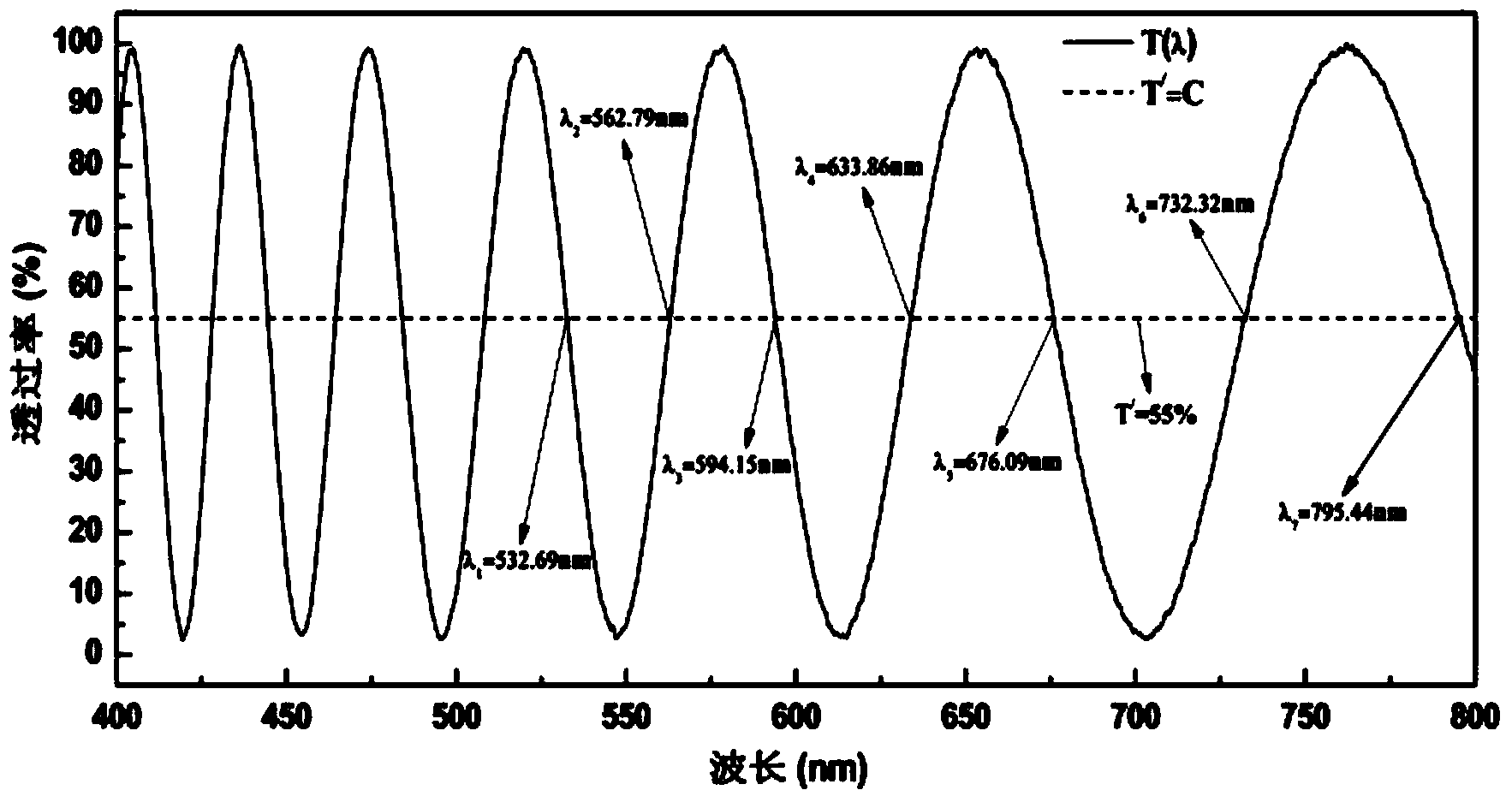

[0082] Embodiment 1 of the present invention such as figure 1 , 2 , 3, a method for accurately measuring the phase retardation of a wave plate is realized by the following device, which includes a light source 1, an aperture 2, a polarizer 3, an analyzer 6, a converging lens 8, a spectrometer 9 and The computer 10, the light source 1 is located in front of the diaphragm 2, and the polarizer 3, the analyzer 6, the converging lens 8 and the spectrometer 9 are placed sequentially along the optical path from the diaphragm 2, and the spectrometer 9 is connected to the computer 10, wherein the polarizer is located Place the first polarizer frame 5 between the detector 3 and the analyzer 6, the first polarizer frame 5 is used to install the wave plate 4 to be measured, and the analyzer 6 is installed on the second polarizer frame 7, the method steps are as follows :

[0083] (1) Turn on the light source and let the light source warm up for more than 15 minutes until the output wave...

Embodiment 2

[0096] Same as Example 1, except that step (5) of this method is: keep the orientation of the polarizer and the analyzer unchanged, install the wave plate to be tested on the first polarizer frame and place it between the polarizer and the analyzer Between the polarizers, rotate the first polarizer frame to adjust the fast axis direction of the wave plate to be tested, find the maximum light intensity by visual inspection of the light intensity of the light emitted from the polarizer, and then rotate the first polarizer clockwise from this position Rotate the wave plate to be measured to 60°, and measure the second spectral intensity curve I obtained from the light emitted from the analyzer according to the measurement procedure in step (4). 2 (λ) and store the corresponding measured data in the computer.

Embodiment 3

[0098] Same as Example 1, except that step (5) of this method is: keep the orientation of the polarizer and the analyzer unchanged, install the wave plate to be tested on the first polarizer frame and place it between the polarizer and the analyzer Between the polarizers, rotate the first polarizer frame to adjust the fast axis direction of the wave plate to be tested, find the maximum light intensity by visual inspection of the light intensity of the light emitted from the polarizer, and then rotate the first polarizer clockwise from this position Rotate the wave plate to be measured to 30°, and measure the second spectral intensity curve I obtained from the light emitted by the analyzer according to the measurement procedure in step (4). 2 (λ) and store the corresponding measured data in the computer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com