Vertical double-shaft numerical control grinder

A CNC grinding machine, vertical technology, applied in the direction of grinding bed, grinding frame, grinding slide, etc., can solve the problems that easily lead to lumbar and cervical spine, physical fatigue, CNC grinding machine can not be displaced and the overall height adjustment, etc. problems, achieve high work efficiency, ensure grinding accuracy, and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

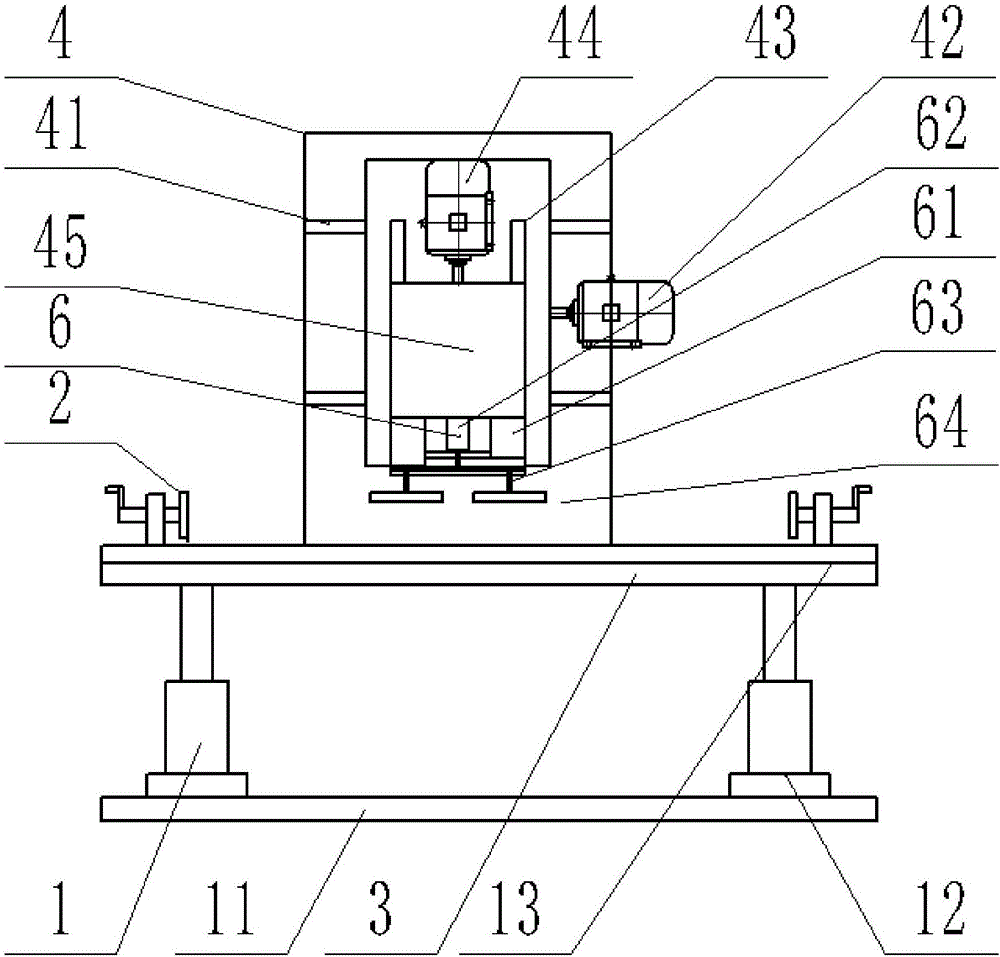

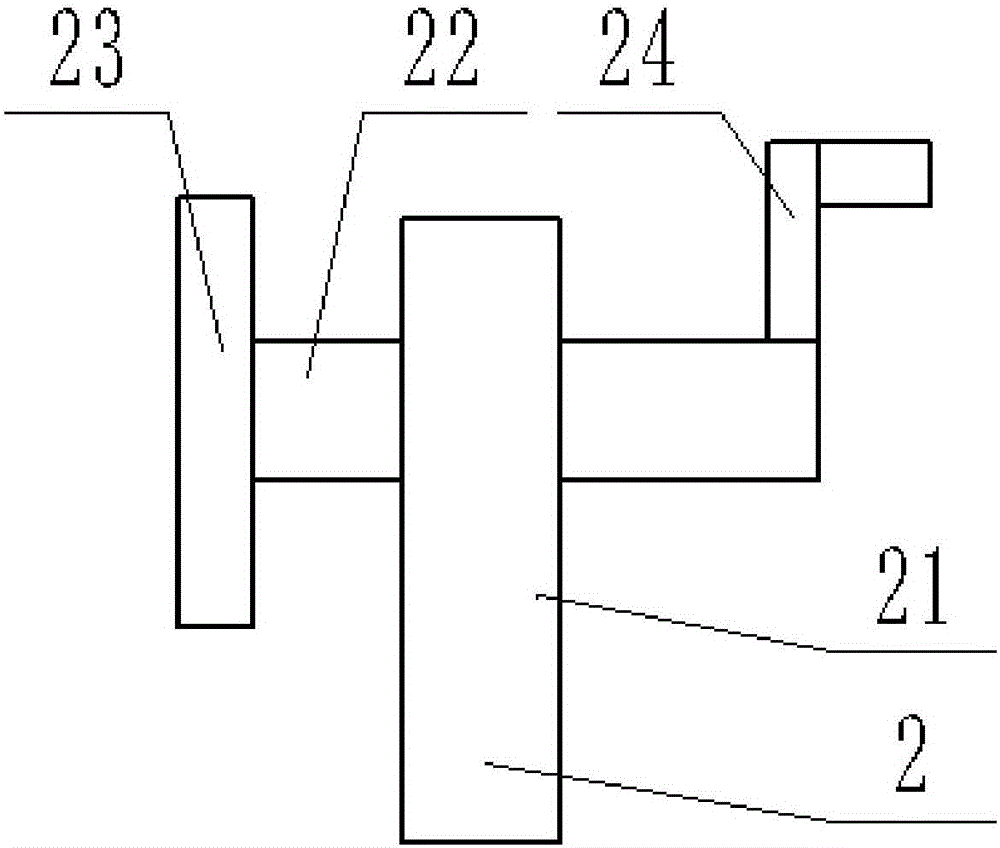

[0016] see Figure 1-2 , a vertical two-axis CNC grinding machine, including a bracket 1, a lateral locking device 2, a workbench 3, a driving mechanism 4 and a grinding device 6, and the bracket 1 includes a base 11, four hydraulic cylinders 12 and a boss seat 13 , the left and right sides of the base 11 are provided with a boss seat 13, and the boss seat 13 is provided with mounting holes, the hydraulic cylinders 12 are symmetrically installed on the four sides of the base 11, and the bottom end of the hydraulic cylinder 12 is fixedly connected with the base 11. The top of the cylinder 12 is connected with the workbench 3 by bolts, and the lift of the workbench 3 is controlled by controlling the lifting of the hydraulic cylinder 12, thereby realizing the adjustment of the overall height of the workpiece; the four sides of the workbench 3 are prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com