Robot polisher

A grinding machine and robot technology, applied in grinding machines, grinding/polishing equipment, and machine tools suitable for grinding the edge of workpieces, etc., can solve problems such as difficult to meet process requirements, yield cannot be guaranteed, etc., to achieve increased automation, Guaranteed grinding accuracy and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

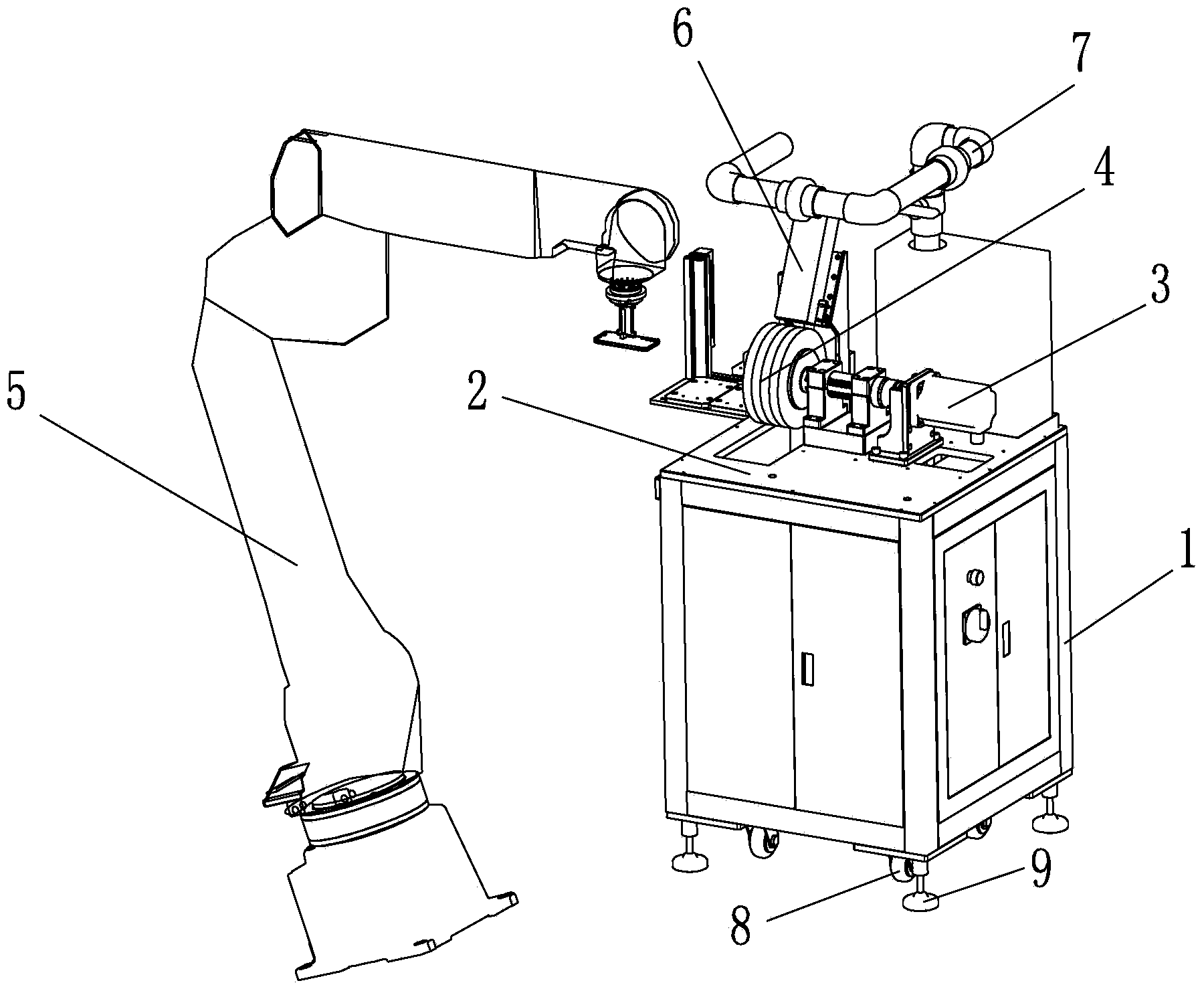

[0013] figure 2 A specific embodiment of the robot grinding machine of the present invention is shown, which includes a frame 1 and a workbench 2 located on the top of the frame. The workbench 2 is equipped with: a six-axis manipulator 5 (also referred to as a six-axis robot) for grabbing workpieces to be polished, a drive motor, and a polishing wheel 4 connected to the drive motor. Accuracy requirements, the drive motor adopts a high-speed servo motor 3, the speed of which can reach 6000r / min, and the speed is controlled by PLC.

[0014] When working, the six-axis manipulator 5 grabs the workpiece to be polished and moves it to the polishing wheel 4, and the servo motor 3 drives the polishing wheel 4 to rotate to polish the workpiece. The six-axis machine manipulator can simulate the product trajectory and can automatically correct and adjust according to actual requirements. Compensation, high grinding precision, high yield rate.

[0015] In this example, an automatic wax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com