Method for sharpening broach for processing turbine wheel disc blade root groove

A blade root groove and steam turbine technology, which is applied to broaches, metal processing equipment, broaching machines, etc., can solve problems such as the decrease in the life of broaches, the decrease in the accuracy of blade root grooves in steam turbine discs, and the decrease in working stability, and achieve gear lift The effect of uniform weight, prolonging the grinding cycle, and smooth and uniform changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

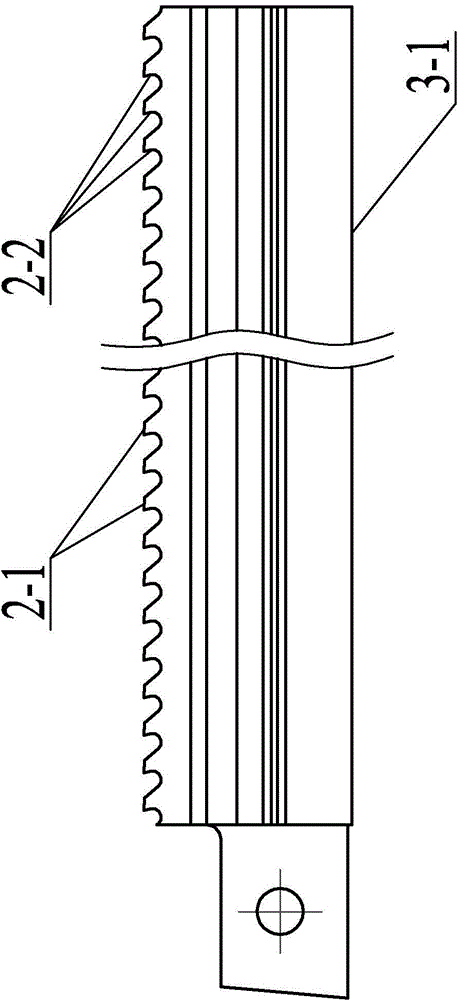

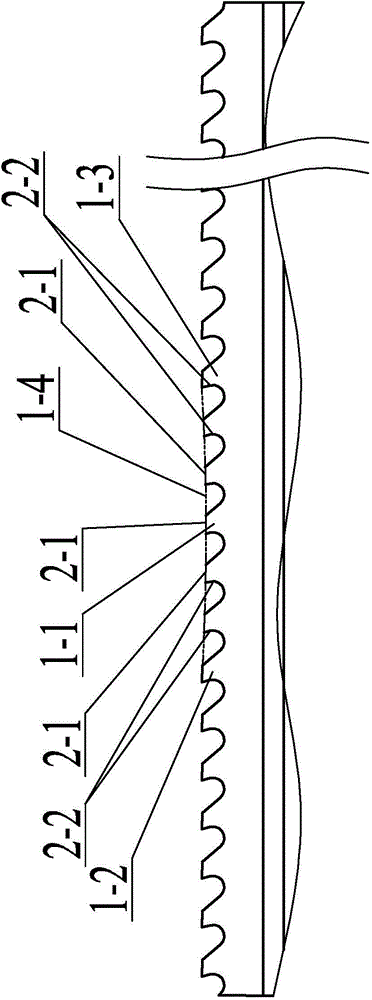

[0019] Specific implementation mode one: combine Figure 1 to Figure 3 Illustrate, the described method of this embodiment is as follows:

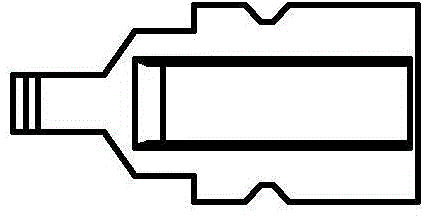

[0020] Step 1, install and fix; use the bottom surface 3-1 of the broach as the positioning surface, and install the broach on the broach grinder;

[0021] Step 2: Grind and quantify the amount of grinding on the unsnapped tooth or the tooth with wear less than 0.3 mm; measure the highest point of the flank 2-1 of the tooth with a meter to find out the chipping or Mark the cutter teeth 1-1 with a wear amount of 0.3mm to 1mm, record the tooth lift amount of the cutter teeth with the wear amount less than 0.3mm, and then grind the rake face 2-2 of the cutter teeth with the wear amount less than 0.3mm, and grind The amount is 0.10mm to 0.15mm, so that the highest point of the flank 2-1 of the cutter tooth with the wear amount less than 0.3mm is reduced, the feed amount of the grinding wheel is 0.01mm, and the speed of the grinding wheel is 3...

specific Embodiment approach 2

[0026] Specific implementation mode two: combination Figure 1 to Figure 3 Explain that the bottom surface 3-1 of the broach described in step 1 of this embodiment is the positioning surface, and the dial gauge or dial gauge is installed and fixed on the grinding wheel arm of the broach grinder, and the dial gauge or dial gauge The contact point is in contact with the bottom surface 3-1, so that the grinding wheel arm moves and the pointer swing range of the dial indicator or dial gauge is checked in real time to measure whether the bottom surface 3-1 is positioned accurately, so that the positioning error of the bottom surface 3-1 is within 0.01mm .

[0027] The undisclosed technical features in this embodiment are the same as those in the first embodiment.

specific Embodiment approach 3

[0028] Specific implementation mode three: combination Figure 1 to Figure 3 Explanation, in the step 2 of the present embodiment, measure the highest point of the cutter tooth flank 2-1 with a meter; install and fix the dial indicator or the dial indicator on the grinding wheel arm of the broach grinder, and the dial indicator or the dial indicator The contact point of the contact is in contact with the flank 2-1 of the cutter tooth, so that the grinding wheel arm is moved and the pointer swing range of the dial indicator or dial indicator is checked in real time to measure the highest point of the flank 2-1 of the cutter tooth.

[0029] The undisclosed technical features in this embodiment are the same as those in the first or second specific embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com