Nanoscale high-flow pin-type sand mill

A large flow, pin-type technology, applied in grain processing, etc., can solve the problems that the central part of the grinding cylinder cannot be effectively cooled, the rotation speed of the rotating shaft is limited, and the effect is not ideal, so as to improve the grinding efficiency, increase the rotation speed, The effect of high pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

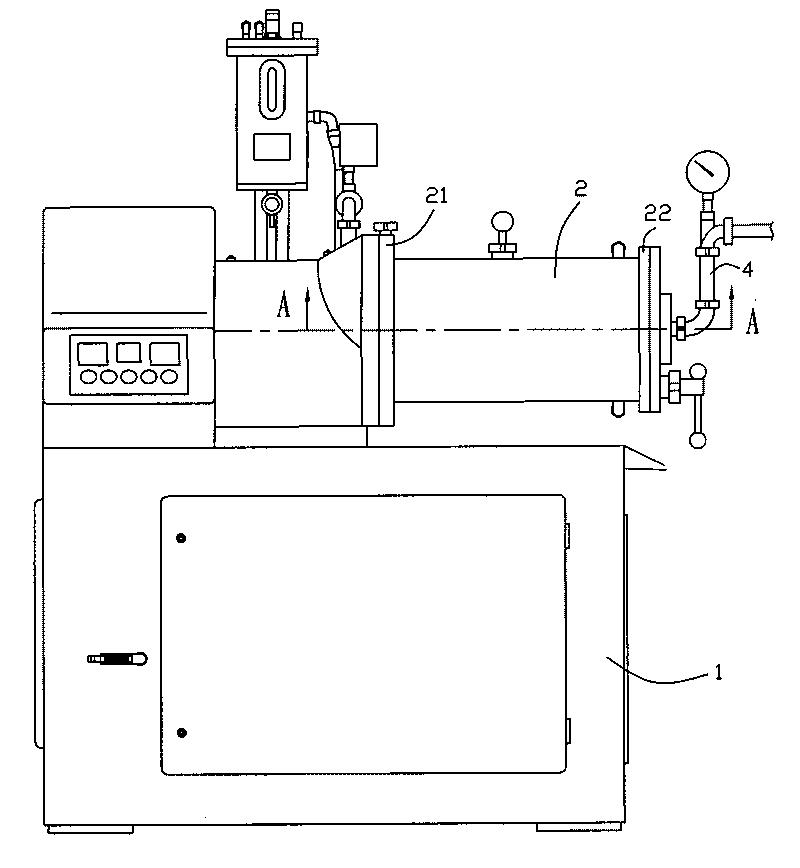

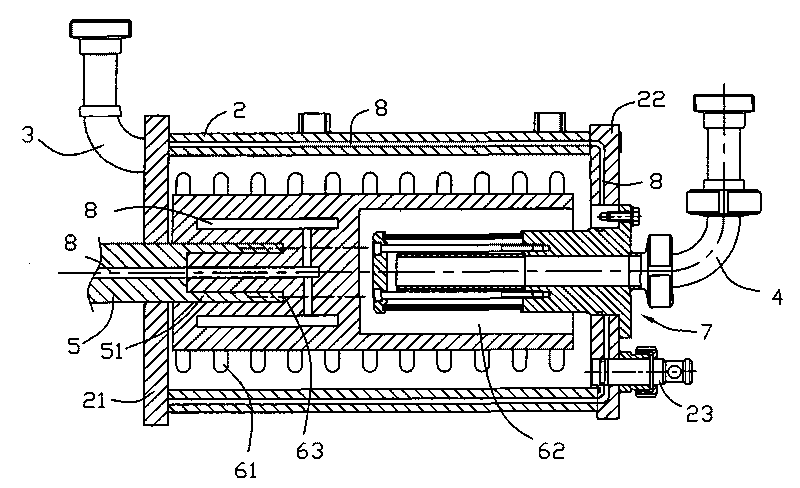

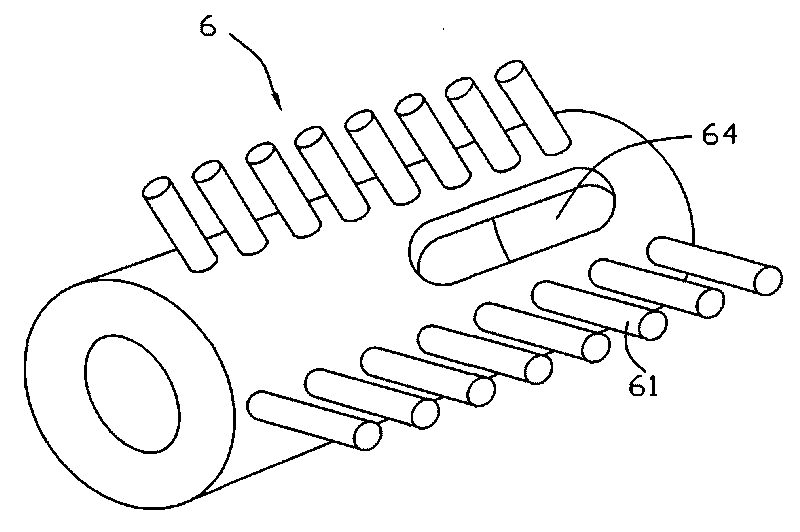

[0017] see Figure 1 to Figure 3 , shows a preferred mode of the nano-scale large-flow pin-pin sand mill of the present invention, including a frame 1 and a grinding cylinder 2 sealed by left and right end covers 21, 22 arranged on the frame, and a rotating shaft 5 passes through The left end cover 21 extends into the grinding cylinder, a rotor 6 is fixed on the rotating shaft 5, and several rows of rod pins 61 are installed on the peripheral wall of the rotor in the axial direction. The material enters the grinding cylinder 2 from the feed pipe 3 at the left end of the grinding cylinder. Under the action of the rotation of the rod pin 61 on the rotor, the material in the grinding cylinder and the grinding medium continuously collide and generate centrifugal force, so that the material is fully dispersed and ground. Then, the principle of dynamic centrifugal separation is used to make the ground material flow out from the discharge pipe 4 through the separator 7 . One end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com