Automatic edge finding and grinding device for specially shaped metal part

A technology for automatic edge finding and special-shaped parts, which is applied in grinding/polishing safety devices, metal processing equipment, and machine tools suitable for grinding the edge of workpieces, etc. problem, to achieve the effect of improving efficiency, ensuring precision and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

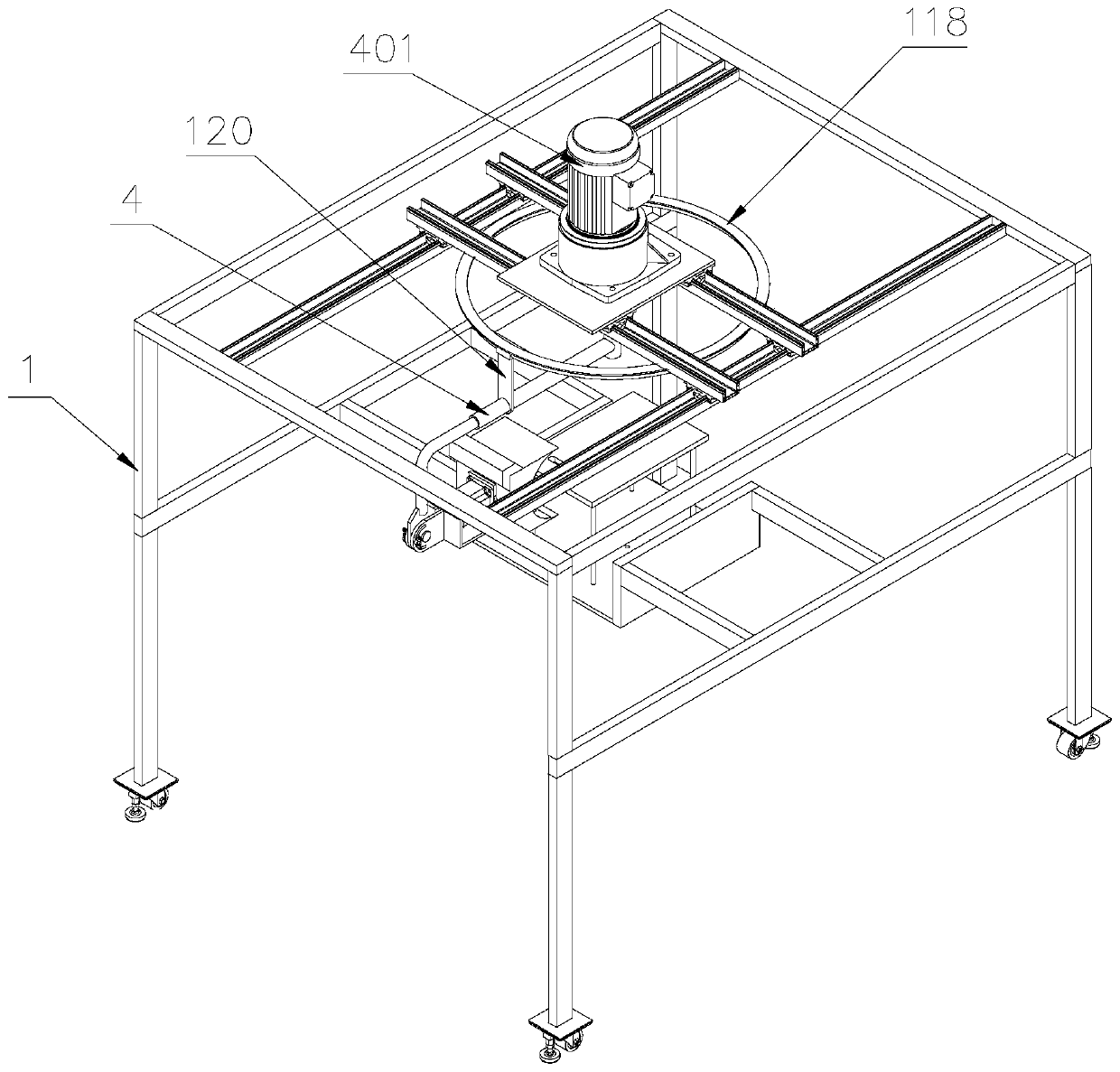

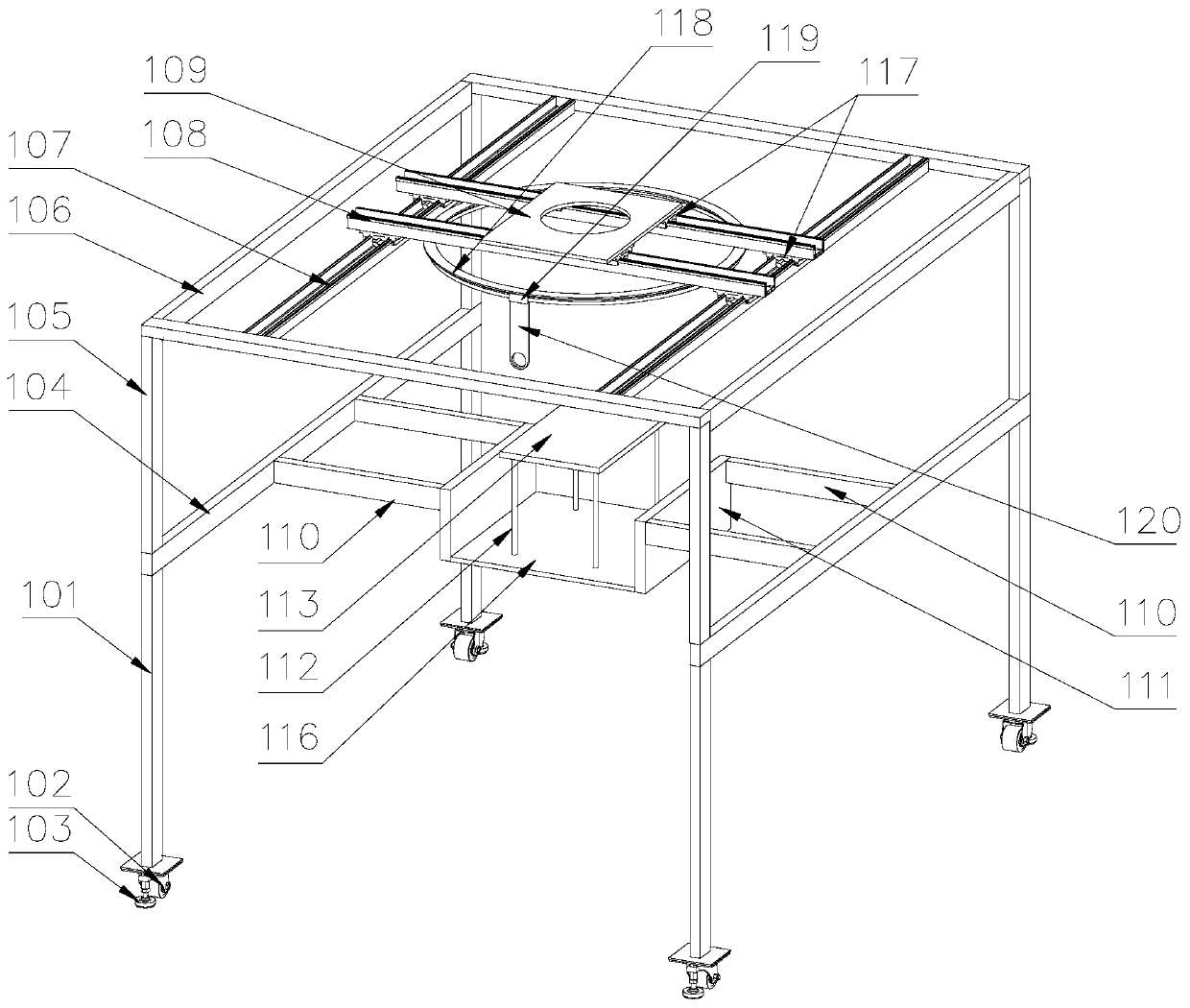

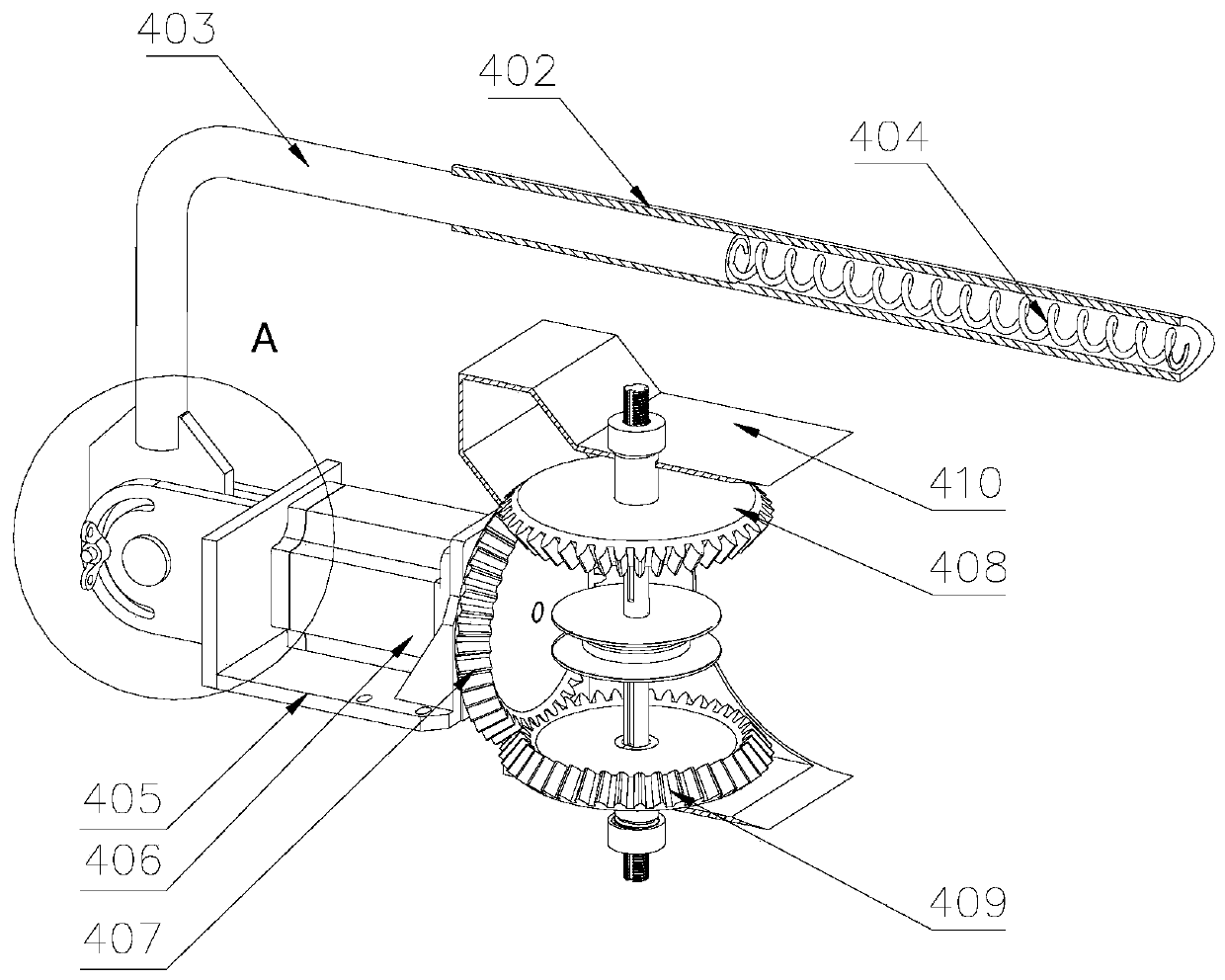

[0051] Please refer to Figure 1-3 , Figure 8 , Figure 12-13 ,

[0052] An automatic edge finding and edging device for special-shaped metal parts, including a support frame 1 and a driving device 4. The support frame 1 includes several legs 101, a first beam 104 connecting the upper ends of the legs 101, and a first beam 104 arranged on the top of the first beam 104. column 105, the second crossbeam 106 connecting the top of the column 105, a bottom plate 116 is arranged between the first crossbeams 104 on both sides, and a connecting plate 111 is connected to both sides of the bottom plate 116, and the connecting plate 111 is connected to the connecting rod 110 through the connecting rod 110. The inner wall of the first beam 104 is fixedly connected; one side of the upper part of the bottom plate 116 is connected with a supporting plate 113 through several support columns 112, and the workpiece 6 is placed on the upper part of the supporting plate 113; the second beam 10...

Embodiment 2

[0058] Please refer to Figure 4 , the difference from Example 1 is that

[0059] In this embodiment, a plurality of first rollers 114 are movably connected between the first beams 104 on both sides, and a plurality of second rollers 115 are movably connected between the first beam 104 and the connecting plate 111. The first rollers 114 and The second roller 115 facilitates the movement of the workpiece 6 on the support frame 1 , which reduces the labor intensity of the workers for lifting the workpiece 6 .

Embodiment 3

[0061] Please refer to Figure 5-6 , the difference from Example 2 is that

[0062]In this embodiment, the lower side of the bottom plate 116 is also provided with a lifting device 2, and the lifting device 2 includes a second motor seat 201 arranged at the lower end of the bottom plate 116, a second motor seat 201 arranged on the second motor seat 201 202, the output shaft of the second motor 202 is connected with a driving pulley 203, the center of the bottom plate 116 is provided with a base 205, one side of the base 205 is movably connected with a driven pulley 204, and the driving pulley 203 is connected with the driven pulley 204 through a belt, and the center of the driven pulley 204 is provided with a threaded hole, and a screw 206 is arranged inside the threaded hole, and one end of the screw 206 is connected with the supporting plate 113; the lower end of the supporting column 112 runs through the bottom plate 116 and connected with the bottom plate 116 in a gap, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com