Door plate lacquering curtain coating production line

A production line and coating technology, applied in the direction of removing smoke and dust, cleaning methods and utensils, grinding machines, etc., can solve the problems of incomplete adsorption of wood chips, affecting the appearance quality of door panels, etc., and achieve the effect of convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

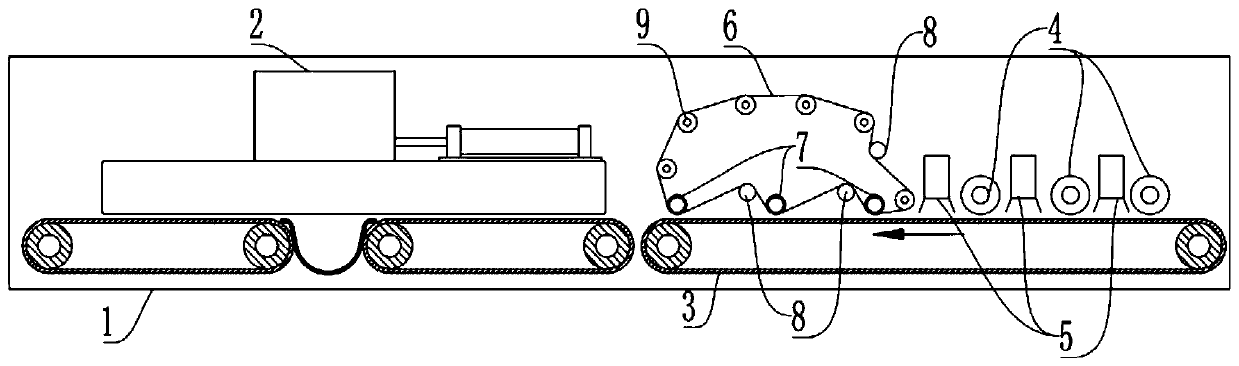

[0043] Embodiment one is basically as attached Figure 1 to Figure 5 Shown:

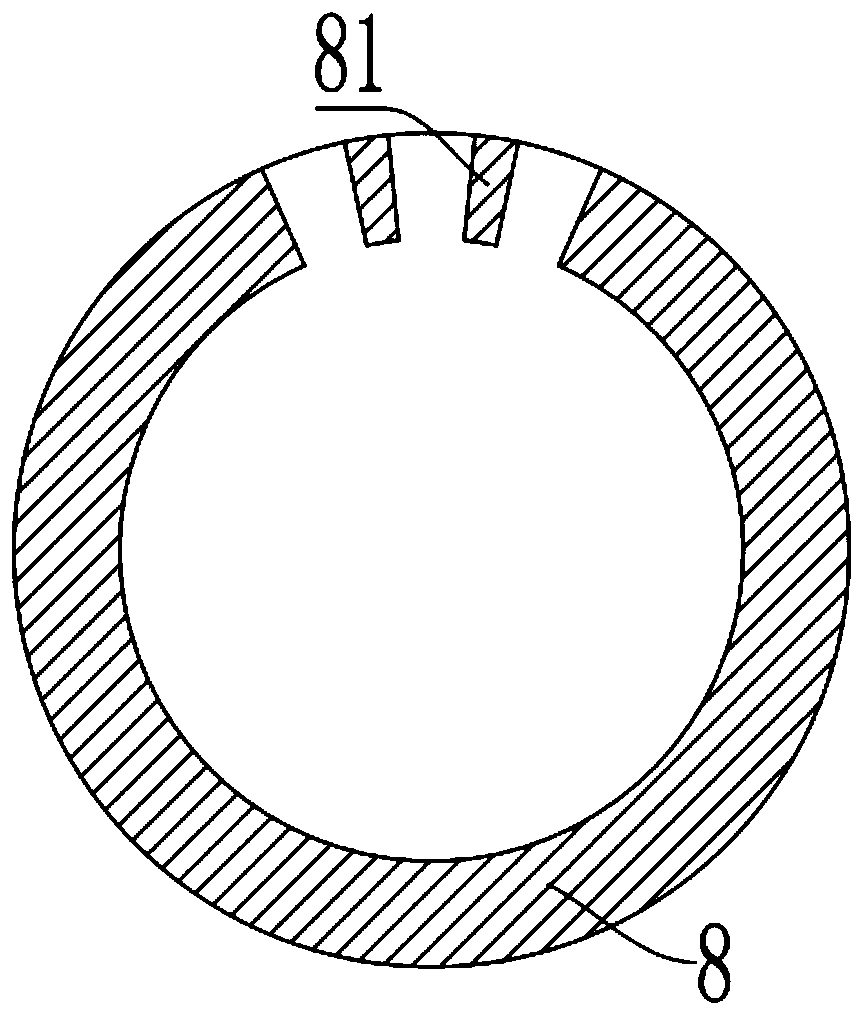

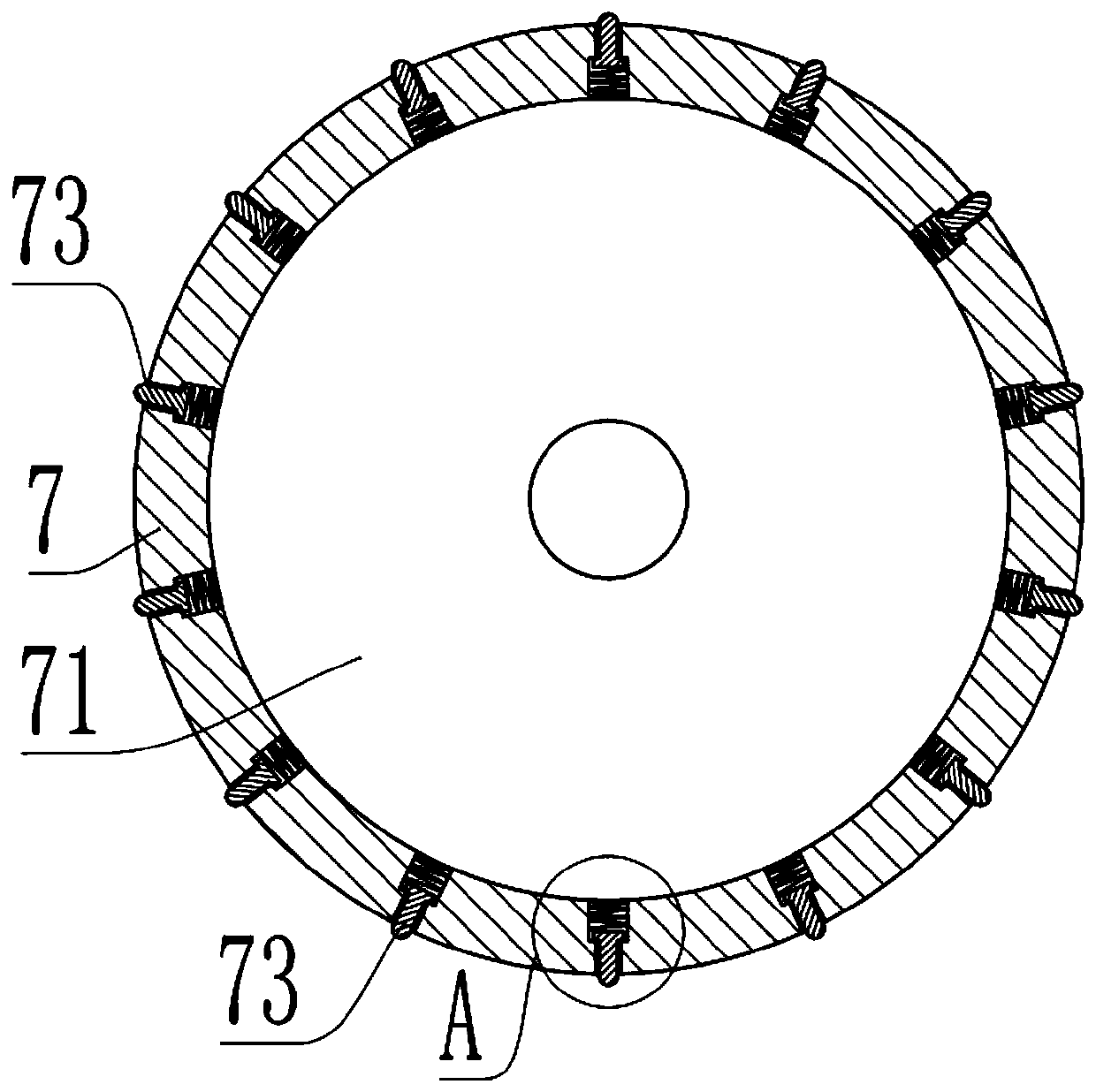

[0044] Paint and flow coating production line for door panels, including frame 1, conveyor belt 3, grinding unit, negative pressure unit, adhesion unit, and flow coating unit, the adhesion unit of the grinding unit, drying chamber 10, and flow coating unit convey the board along the conveyor belt 3 The directions are distributed sequentially, and there is a negative pressure unit behind each grinding unit.

[0045] to combine figure 1 , the grinding unit includes three rotating rollers 4 that are connected in rotation on the frame 1, each rotating roller 4 is driven by a separate motor, the outer periphery of the rotating roller 4 is bonded with sandpaper, and the rotating roller 4 is parallel to the conveyor belt 3; The rotating speeds of the rotating rollers 4 are different, and the rotating speeds of the rotating rollers 4 increase sequentially from right to left.

[0046]The negative pressure ...

Embodiment 2

[0059] combine Figure 6 , embodiment two increases drying chamber 10 on the basis of embodiment one, namely between adhesion unit and shower coating unit, drying chamber 10 is set, is convenient to adopting the board after alcohol adhesion sawdust and dust to dry, After the board is dry, do the spray coating, so as to avoid the situation that the board is not completely dry due to the presence of alcohol, which will affect the quality of the subsequent board.

Embodiment 3

[0061] Embodiment three is basically as attached Figure 7 to Figure 11 As shown, embodiment two has carried out following improvement on the basis of embodiment one, specifically as follows:

[0062] The number of conveyor belts 3 is three, and a reflow tank 12 is arranged between the two conveyor belts 3 , and the reflow tank 12 is facing the edge 13 of the coating knife of the coating substrate 2 .

[0063] combine Figure 10 , A recovery box 14 is also fixedly installed on the frame 1, and the recovery box 14 communicates with the return tank 12.

[0064] combine Figure 8 to Figure 11 , the backflow groove 12 is slidably connected with a moving rod 15 (the moving rod 15 can move in the length direction of itself), the bottom of the backflow groove 12 is arc-shaped, and the moving rod 15 is covered with two springs 16, and the spring 16 and the backflow groove The arc-shaped bottom of 12 offsets; The middle part of moving bar 15 is fixedly connected with baffle plate 17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com