Polishing and deburring device

A deburring and charging technology, which is applied in the direction of abrasive feeding device, used abrasive processing device, separation method, etc., can solve the problems of high labor intensity of workers, impurities blocking pipelines, environmental pollution, etc., to prevent Excessive friction and workpiece scratches, ensuring stable movement, and easy lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

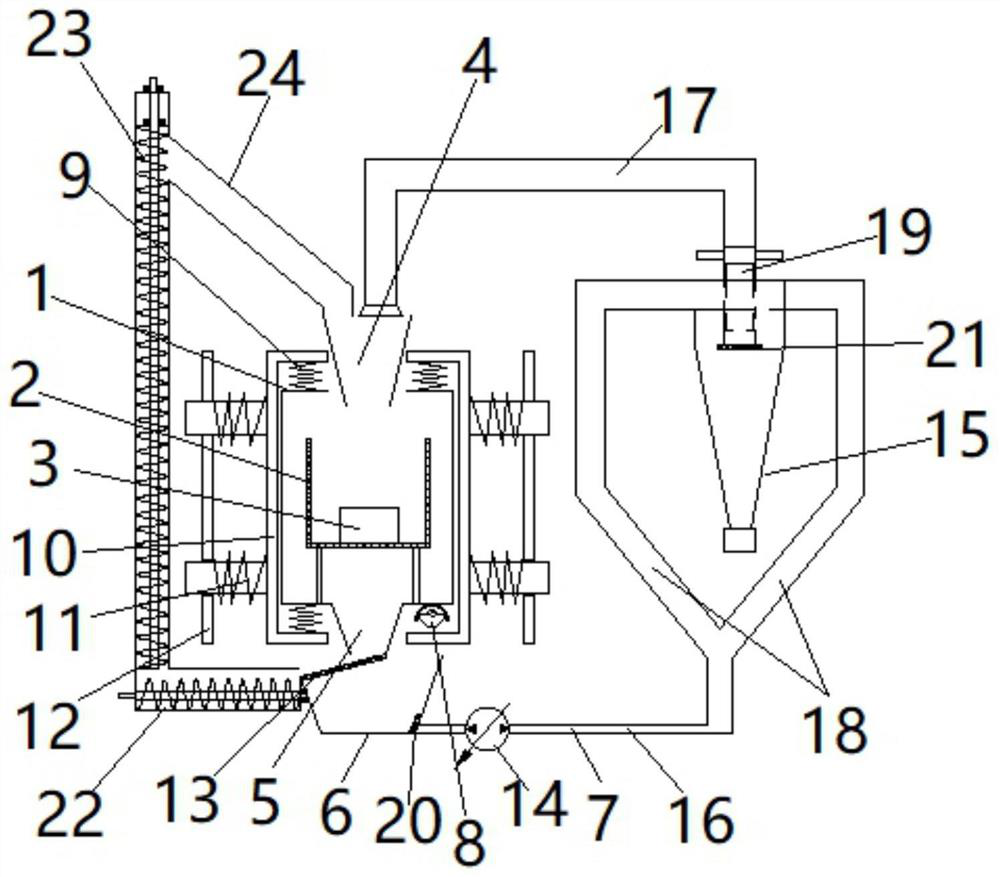

[0035] A polishing and deburring device, including a working chamber 1, a conveying assembly, an oil tank mechanism, a first moving assembly, a second moving assembly and a limit assembly, such as Figure 1-2 As shown, the details are as follows:

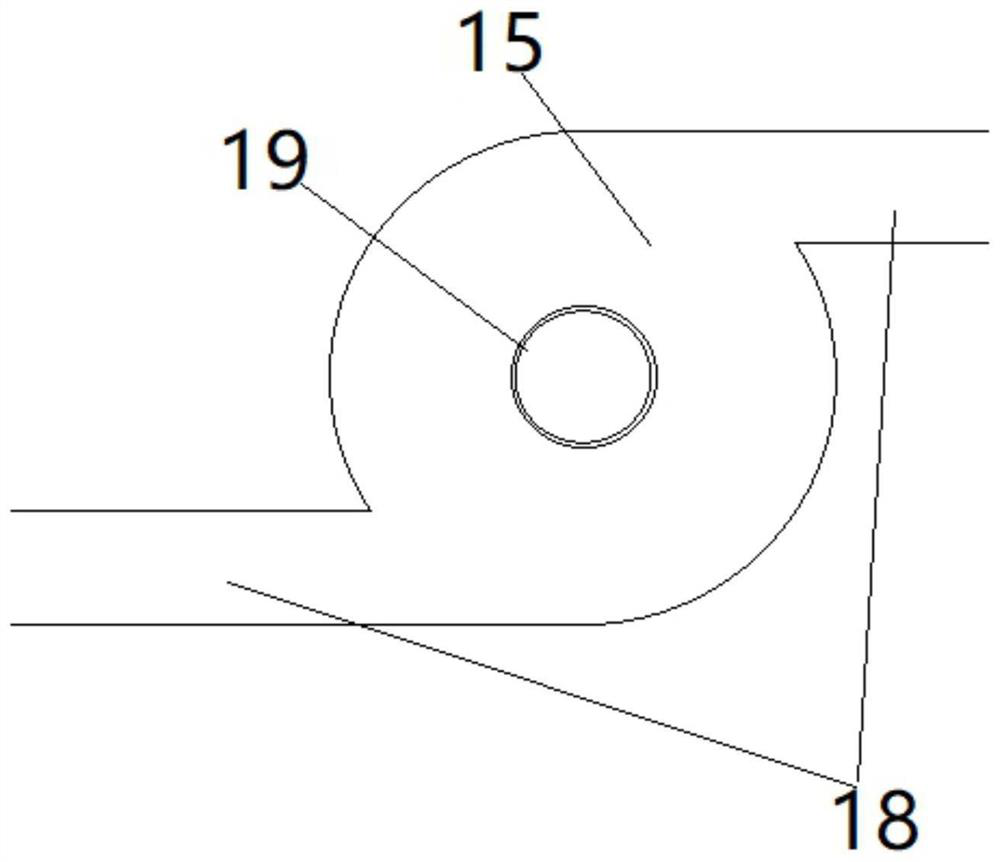

[0036] Such as figure 1As shown, the shape of the working room is a rectangular box, and the loading basket 2 (the workpiece 3 is arranged in the charging basket) is supported in the inside of the working room by a support rod; and the upper and lower ends of the working room are correspondingly provided with feeding ports 4 and outlet 5, the loading basket corresponds to the direction in which the abrasive material falls along the material inlet and outlet, and the abrasive material falls into the loading basket from the material inlet, and moves (vibrates) through the working room so that the abrasive material and the workpiece are fully contact to realize the grinding and polishing of the workpiece; there is a mesh on the loadin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com