Efficient feed drying device

A drying device and feed technology, applied in drying, dryer, drying gas arrangement and other directions, can solve the problems of low drying efficiency, direct drying of feed, etc., achieve high-efficiency drying, improve unevenness, improve The effect of drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

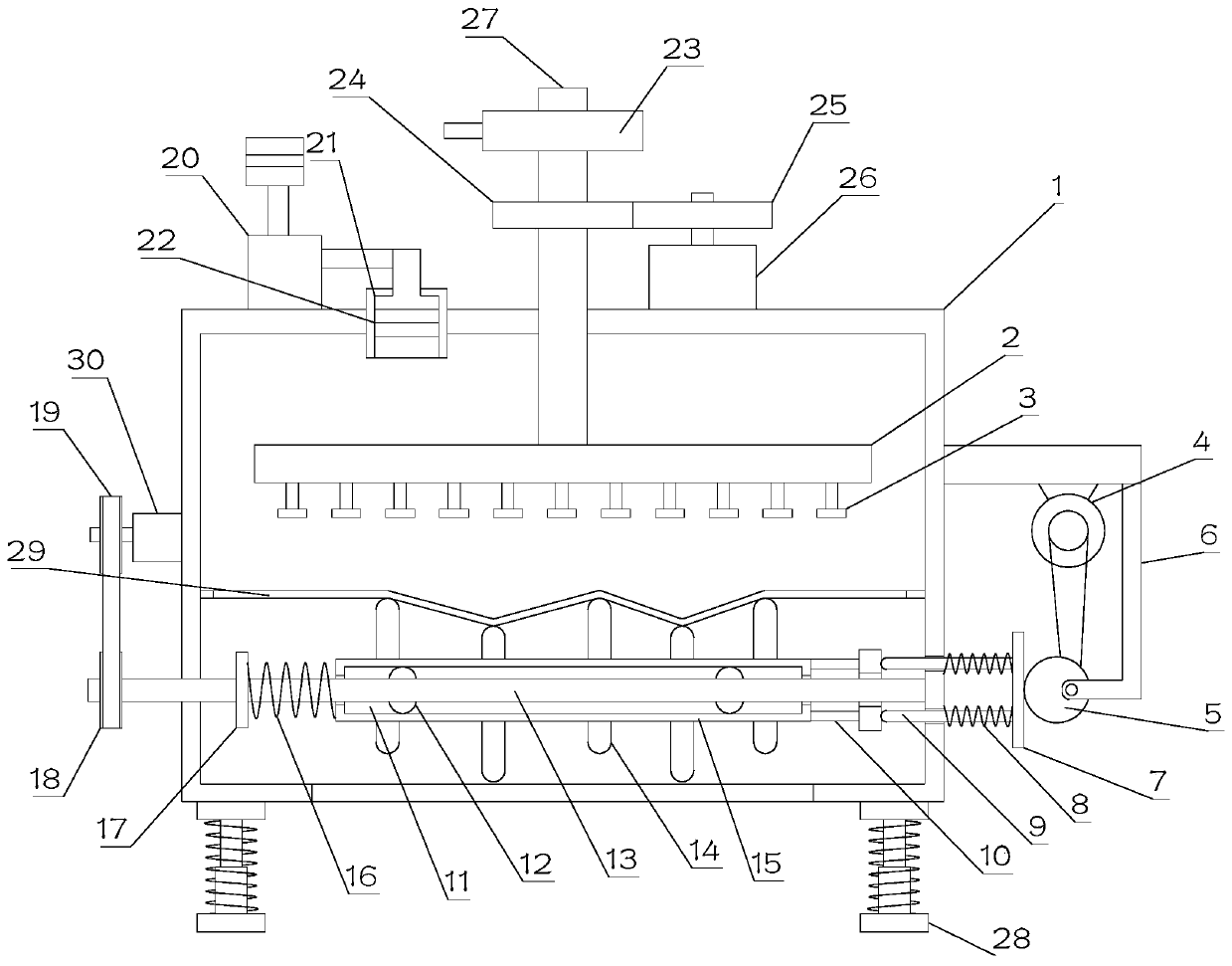

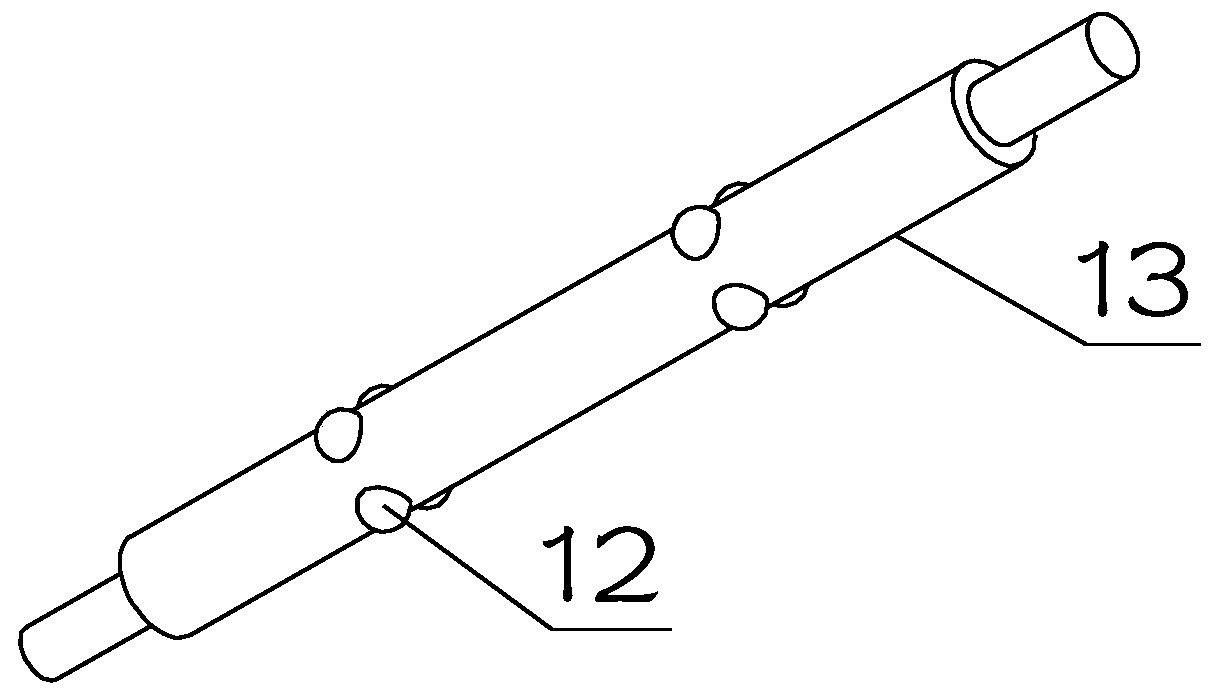

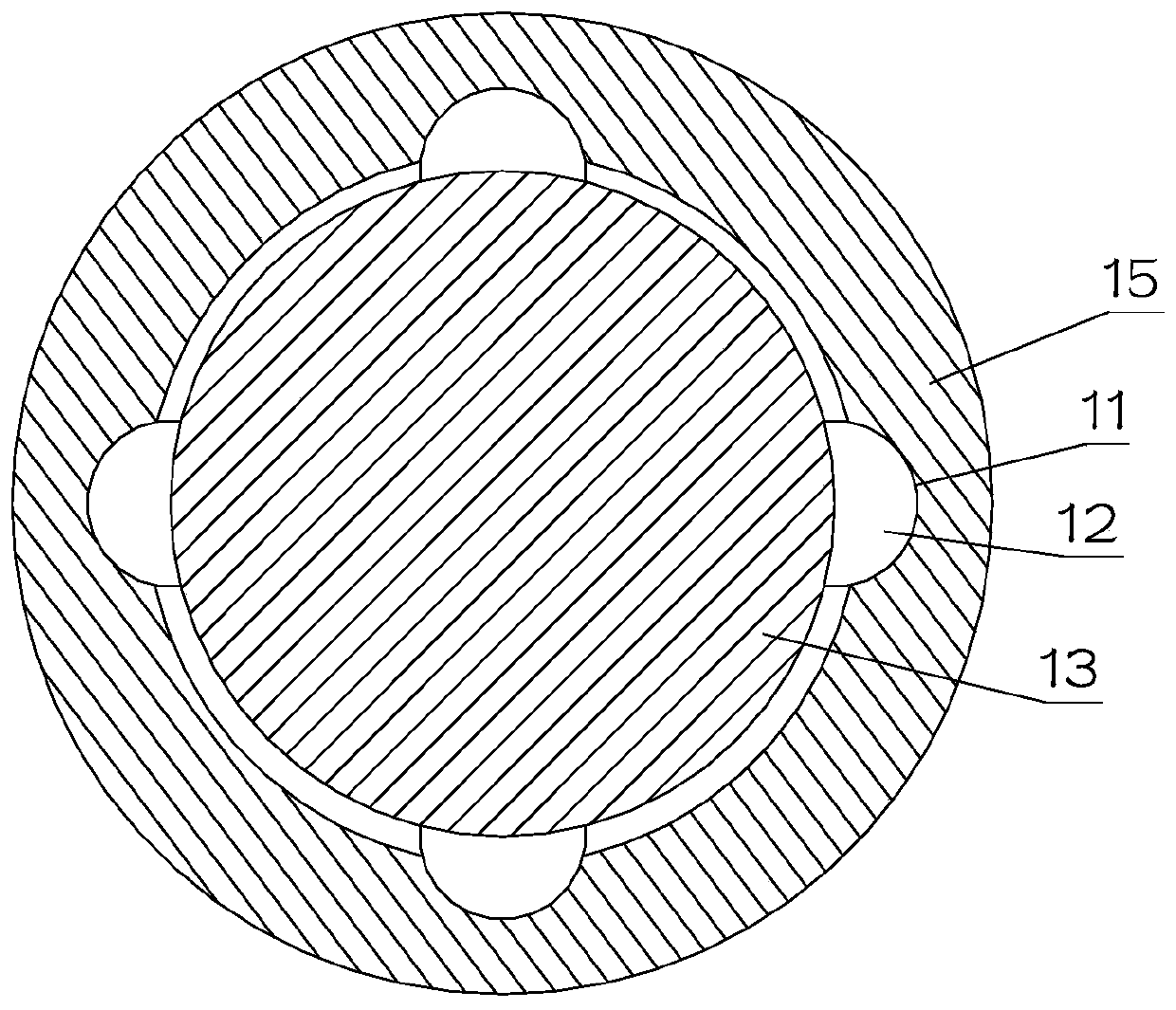

[0021] see Figure 1~3 , in Embodiment 1 of the present invention, a high-efficiency feed drying device includes a drying main body 1 with a drying chamber inside, an elastic drying film 29 is arranged inside the drying main body 1, and a sliding sleeve 15 is arranged outside There are multiple cams 14 with different installation angles. The upper ends of the cams 14 are in contact with the bottom of the elastic drying film 29, and are used to drive the elastic drying film 29 to reciprocate up and down; The rotating shaft 13 on 1 is used to drive the rotating shaft 13 to rotate. The outer side of the rotating shaft 13 is provided with a protrusion 12. The protrusion 12 slides left and right and is arranged on the sliding groove inside the sliding sleeve 15. The B sleeve on the rotating shaft 13 The two ends of the elastic member 16 are respectively fixed on one end of the sliding sleeve 15 and the supporting block 17, and the supporting block 17 is fixedly installed on the sli...

Embodiment 2

[0024] see Figure 1~3 The main difference between Embodiment 2 and Embodiment 1 is that a door is provided on the side of the drying body 1 for adding feed to the inside of the drying body 1 .

[0025] The rotating assembly includes an A belt pulley 18 sleeved on the rotating shaft 13, a B belt pulley 19 and a C motor 30 connected in transmission with the A belt pulley 18, the B belt pulley 19 is mounted on the output end of the C motor 30, and the C motor 30 is fixedly mounted on the oven. Dry main body 1. The C motor 30 is energized to provide power for the rotation of the rotating shaft 13 through the B pulley 19 and the A pulley 18 .

[0026] The reciprocating assembly includes a mating sleeve 10 fixedly installed on the other end of the sliding sleeve 15, the mating sleeve 10 is set on the rotating shaft 13, the pole 9 is in contact with the mating sleeve 10, and the pole 9 runs through the drying body 1 side The pole 9 is fixed on the end away from the mating sleeve 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com