Non-woven fabric facial mask paper production equipment and process

A technology for production equipment and cloth mask, applied in textile and papermaking, cutting of textile materials, metal processing, etc., can solve problems such as waste and adhesion, and achieve the effect of reducing waste, reducing adhesion and reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

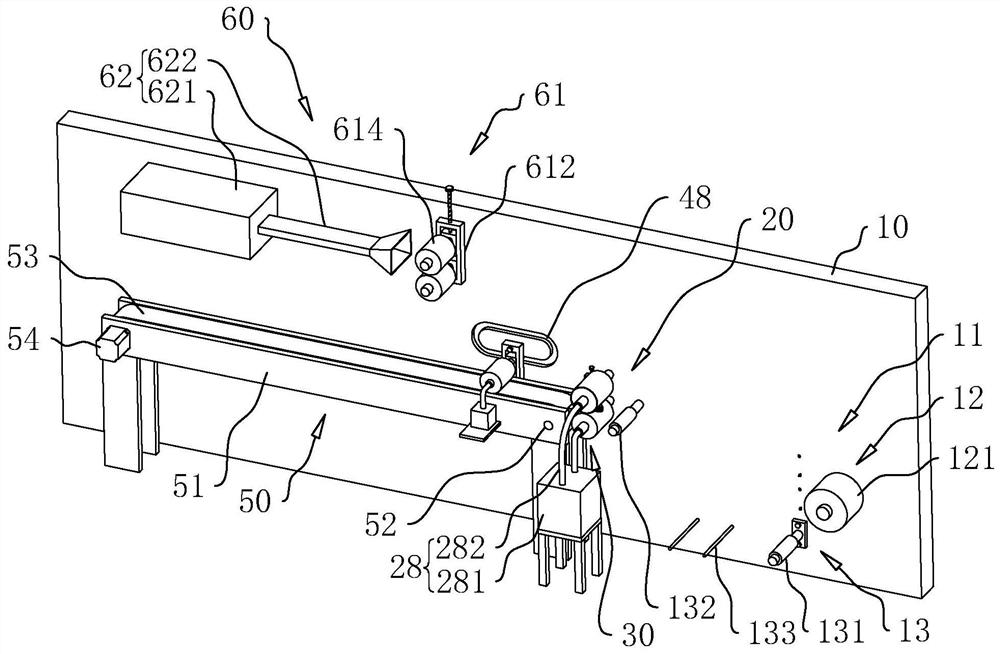

[0041] The present application discloses a production equipment for non-woven mask paper. Refer figure 1 The substrate 10, the lower surface of the substrate 10 is fixed to the ground, and the substrate 10 is sequentially mounted in the conductive direction in the conductive direction, the shaping mechanism 11, the cutting mechanism 20, the tensioning mechanism 30, the flat mechanism 40, the conveying mechanism 50 and the collection The material 60 is used to make the non-woven fabric, cut the mask, tension nonwoven fabric, flattening and separation mask, transport mask, collect waste.

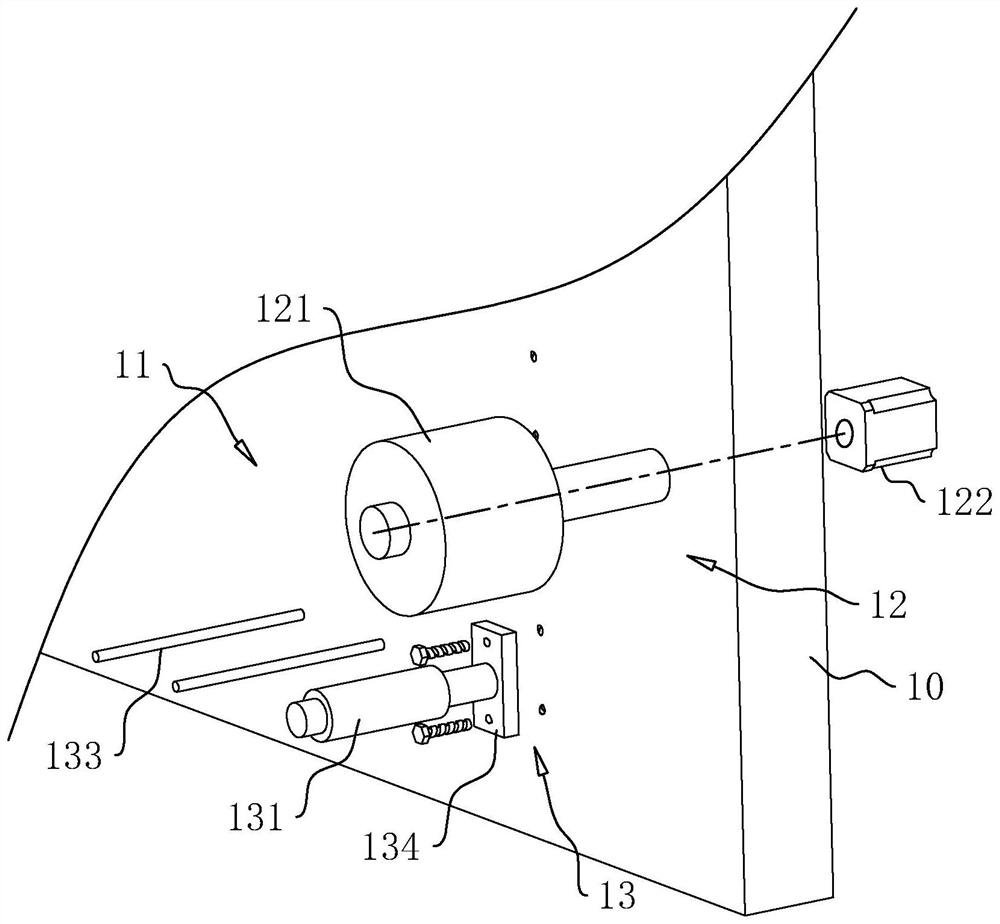

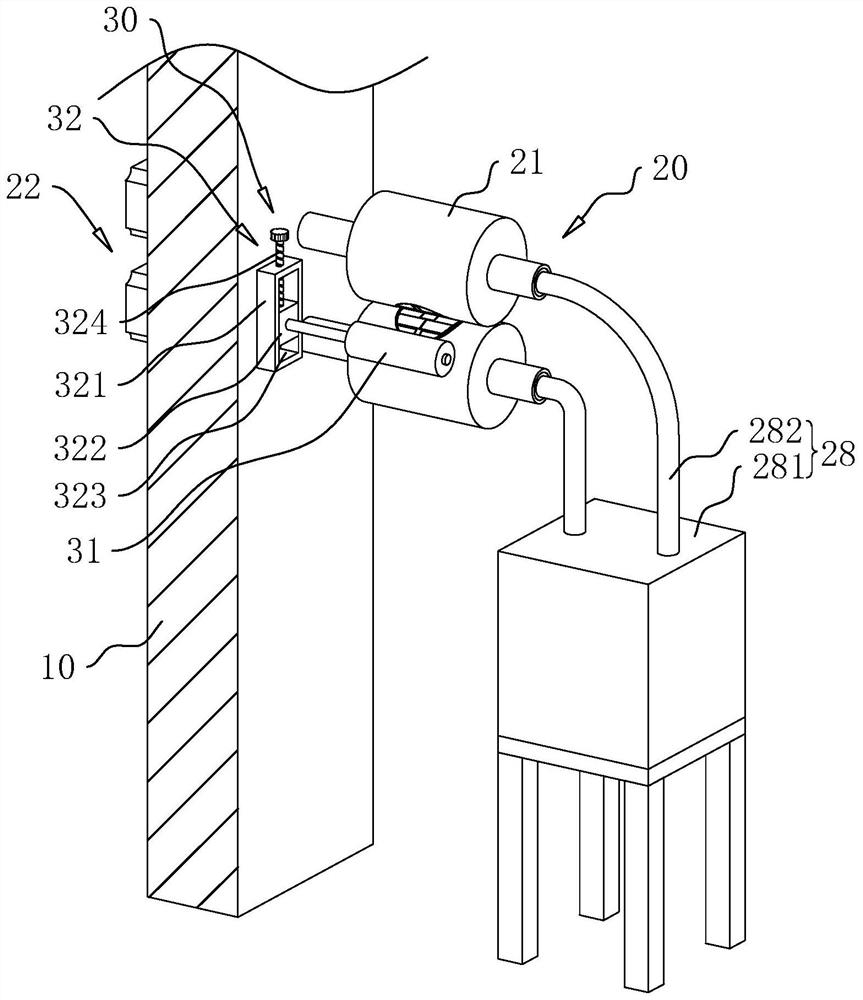

[0042] Specific, reference figure 1 with figure 2 The arrowing mechanism 11 includes a winding assembly 12 and a conductive assembly 13, and the arrow assembly 12 includes a shackle roller 121 and a plastic motor 122, and the arrangement roller 121 is inserted within the substrate 10, and is rotated through the bearing to the substrate. 10. The discharge motor 122 is fixedly mounted on the substra...

Embodiment 2

[0065] The present application discloses a production process of non-woven mask paper. Refer figure 1 , Including the following steps:

[0066] A, the arrowing mechanism 11 is discharged and the nonwoven cloth is tensioned, and the two knife roller 21 is rotated, and the two knife die 23 is abutment, cutting the mask, the second supply The gas 28 is started, and the waste cutting the eye mold 231 and the mouth mold 232 is ejected by airflow;

[0067] B. During the cutting process, the nonwoven fabric is adjacent to the blade roller 21, and the elastic member 25 is pressed in a retraction state. When the elastic member 25 is no longer pressed, the extruded mask is eradicated, and the mask of the cut it is stressed. Separate.

[0068] C. After the mask is introduced from the cutting mechanism 20, the conveying mechanism 50 is transmitted to the discharge side, and the exhibition roller 47 presses the mask while moving, the first supply gas 46 is activated, and vibration is generated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com