Production system for heat exchanger processing

A production system and heat exchanger technology, applied in metal processing equipment, manufacturing tools, heat exchange equipment, etc., can solve problems such as low efficiency, time-consuming and labor-intensive, and increased labor intensity of staff, and achieve stable feeding and good separation effect , good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

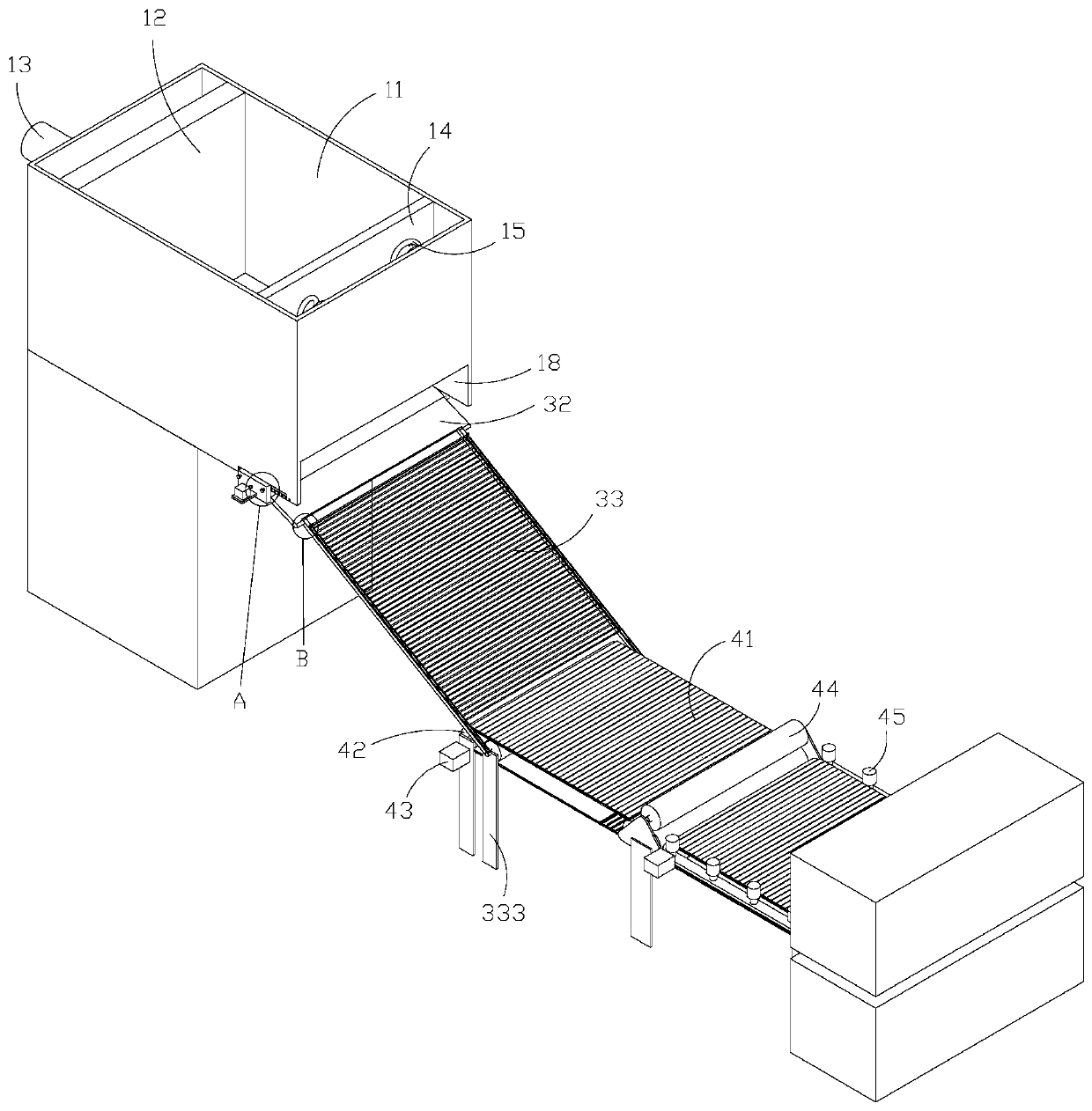

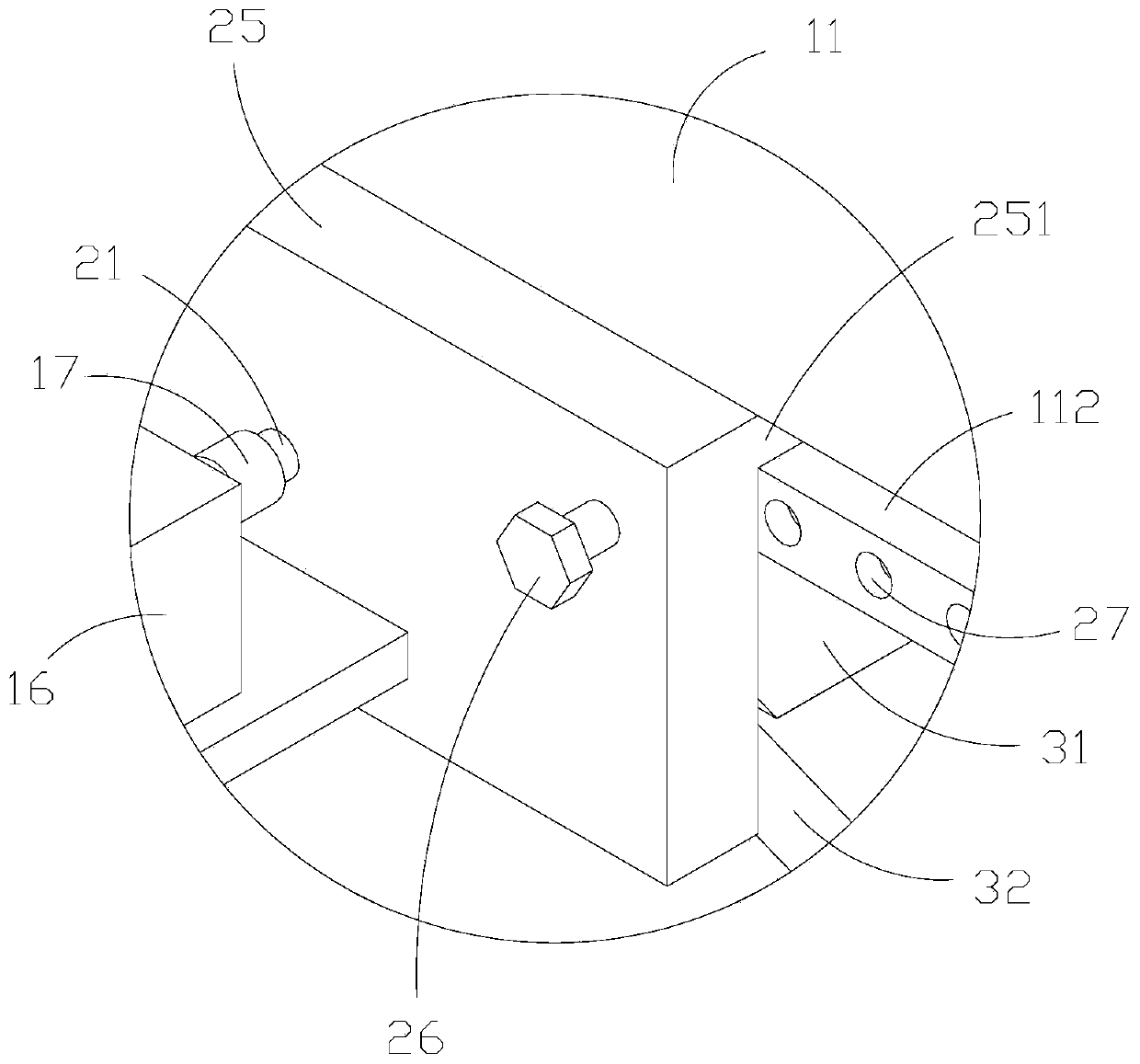

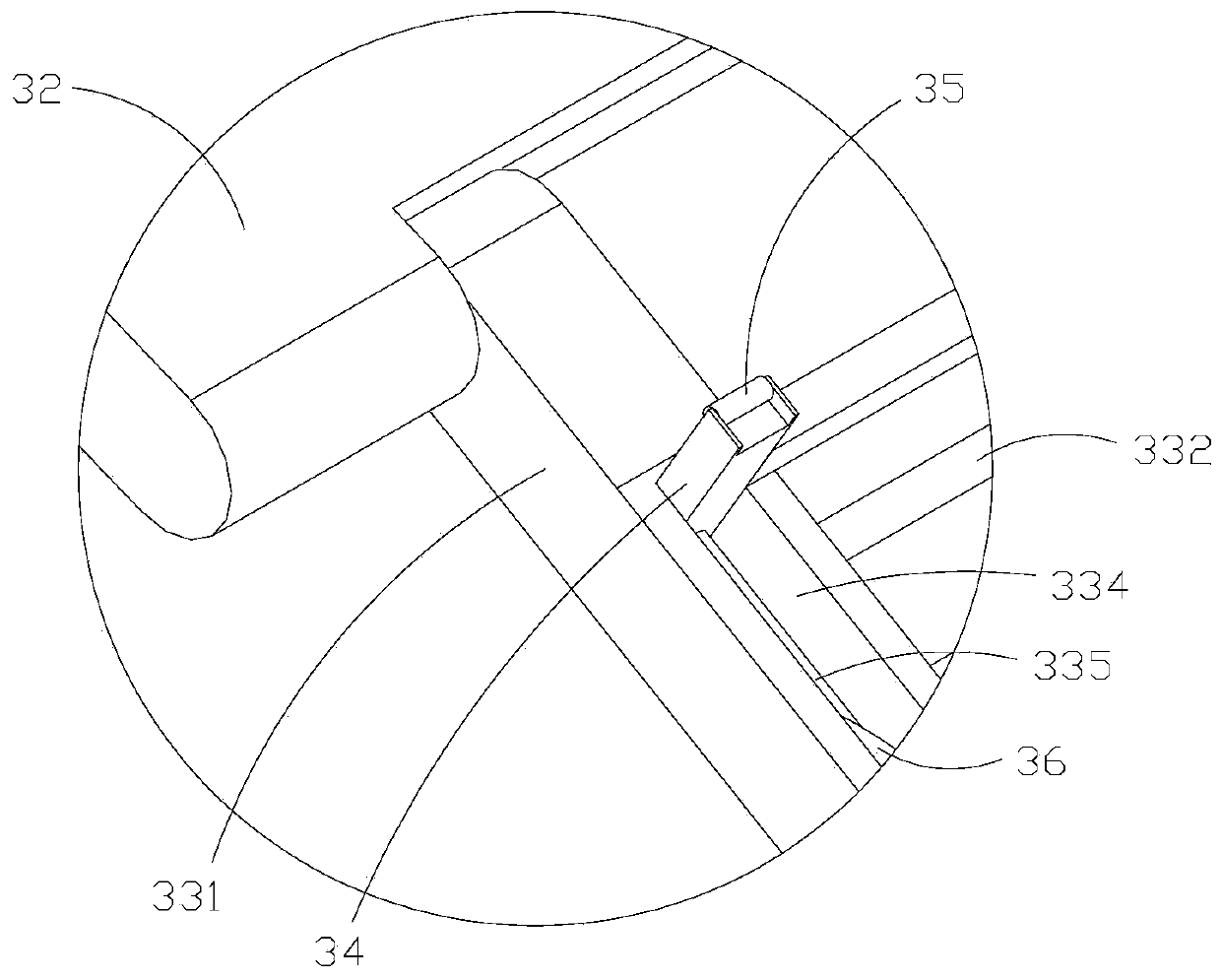

[0019] Such as Figure 1-6 As shown, a production system for heat exchanger processing, including a hydraulic device, an automatic feeding device and a conveying device; wherein the hydraulic device is a hydraulic press purchased on the market, which is the prior art and is not the focus of this application. Therefore, it will not be described in detail here; the automatic unloading device includes a discharge hopper 11, a pusher plate 12, a pusher drive member 13, a feeder plate 14, an elastic member 15, a feed opening 18, a material distribution structure and a material guide structure; The hopper is made of metal material and is opened in a cuboid structure with an upper opening, which is convenient for placing materials (in this application, metal plates, such as steel plates). The materials are neatly arranged and stacked along the length of the hopper; The lower right corner is formed by cutting off part of the bottom surface and part of the side of the discharge hopper;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com