Sheet conveying roller and production method therefor

a conveying roller and conveying roller technology, applied in the direction of manufacturing tools, roads, roads, etc., can solve the problems of paper dust and dirt generated by paper sheets that are liable to adhere to the outer peripheral surface of the elastic member, reduce the contact area, and sheet transportation failure, so as to suppress the sheet transportation failure, reduce the amount of paper dust, and prevent the sheet from being wrinkled or indented

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

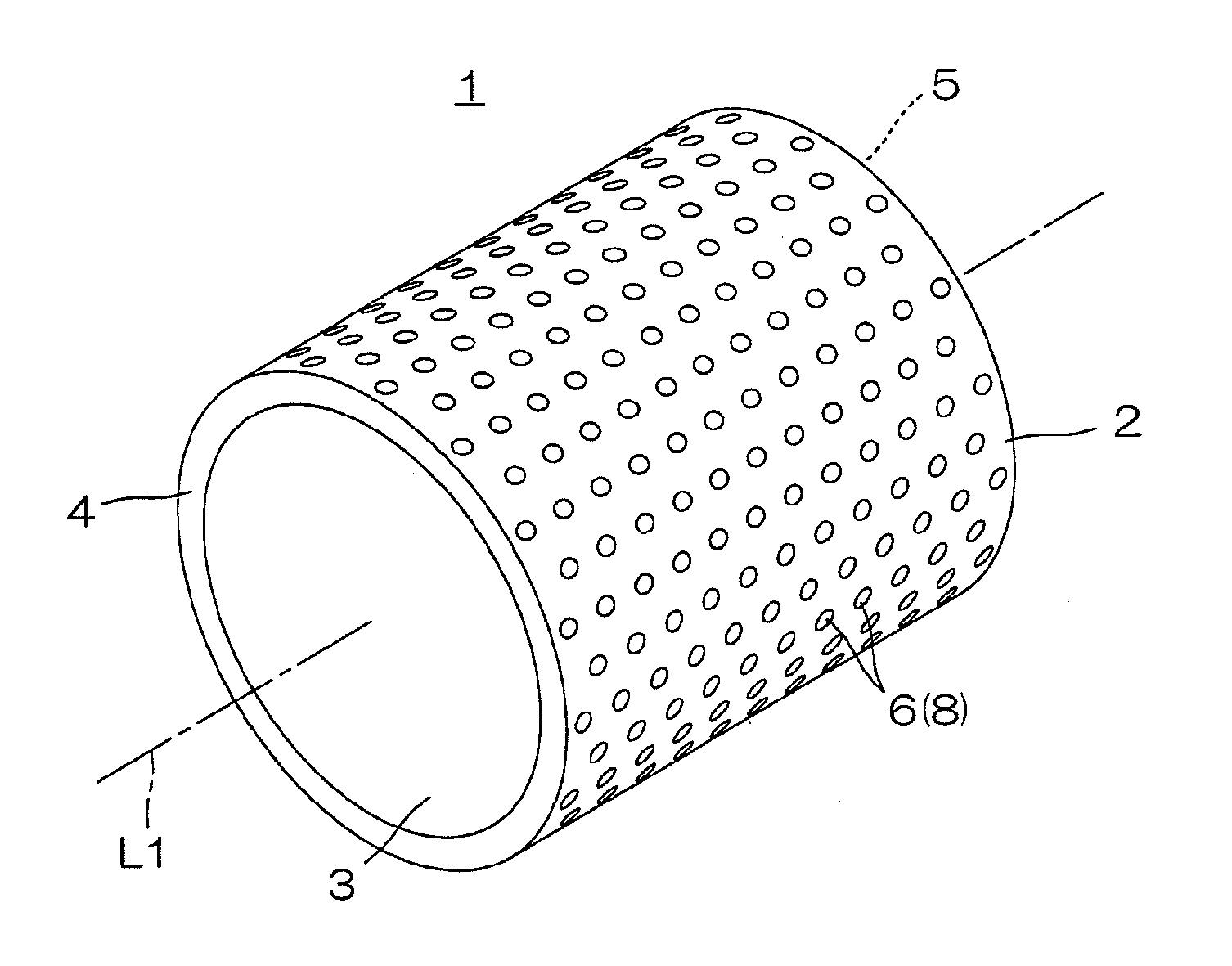

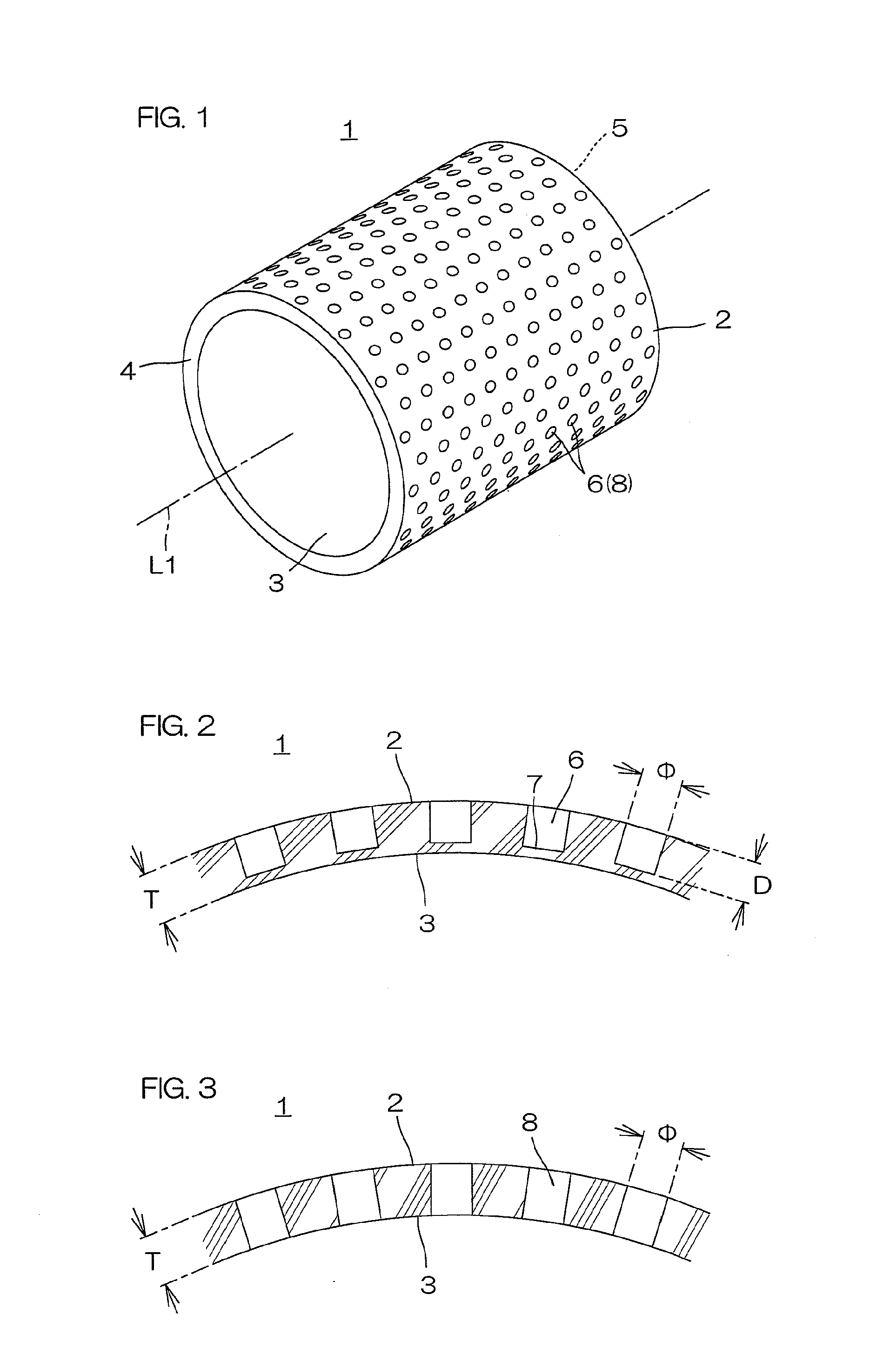

[0113]An elastic member 1 having a three-dimensional shape as shown in FIG. 1, an outer diameter of 24.6 mm and a width of 28.5 mm as measured in a center axis L1 direction thereof and including a plurality of through-holes 8 each having a round plan shape as seen perpendicularly to the outer peripheral surface 2 and arranged in an arrangement as shown in FIG. 1 was produced by the vulcanization utilizing the mold 16 shown in FIG. 6, the grinding of the grinding margin for the exposure of the through-holes 8, and the cutting of the opposite end portions thereof. A mold temperature of 160° C. to 170° C. and a vulcanization period of 20 minutes were employed for vulcanization conditions.

[0114]Such elastic members 1 were produced with the outer diameter, the number and the interval of the projections 21 for the through-holes 8 changed to change the opening diameter Φ and the number of the through-holes 8 aligned in each line extending in the center axis L1 direction (in a line containi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com