Discharging device for mechanical equipment

A technology for mechanical equipment and material cutting, applied in the field of mechanical equipment, can solve the problems of inconvenient material dredging, unfavorable equipment, material residue, etc., and achieve the effect of preventing excessive workload, rational design of structure and principle, and improving service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

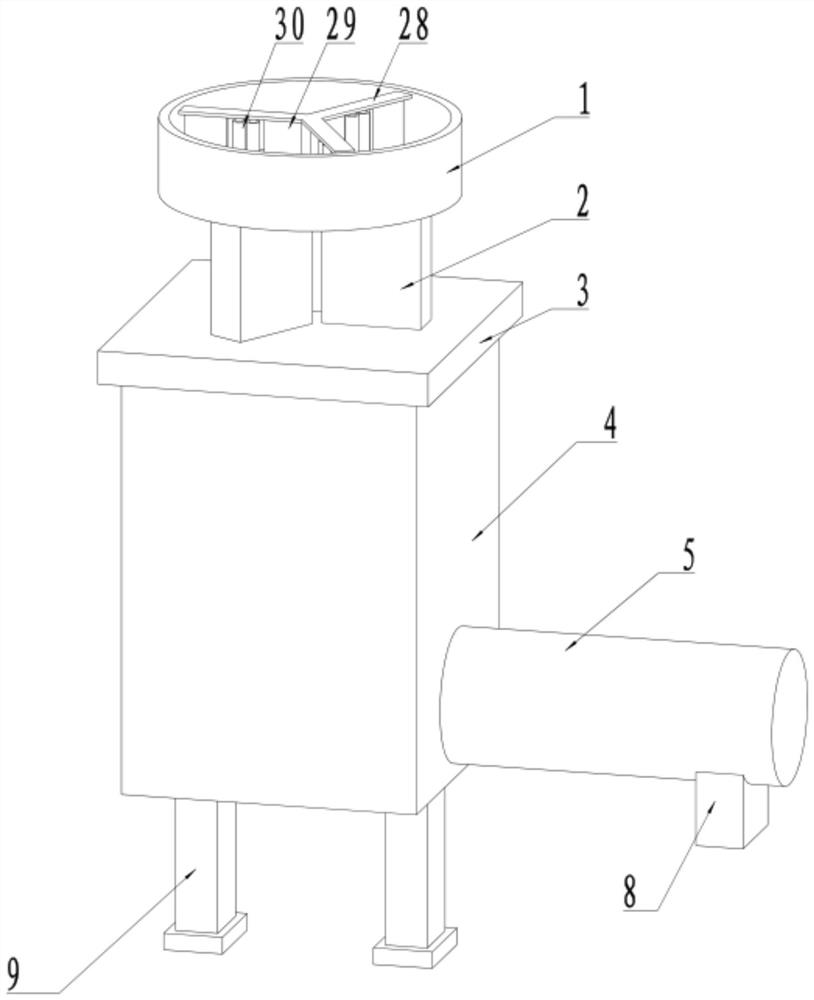

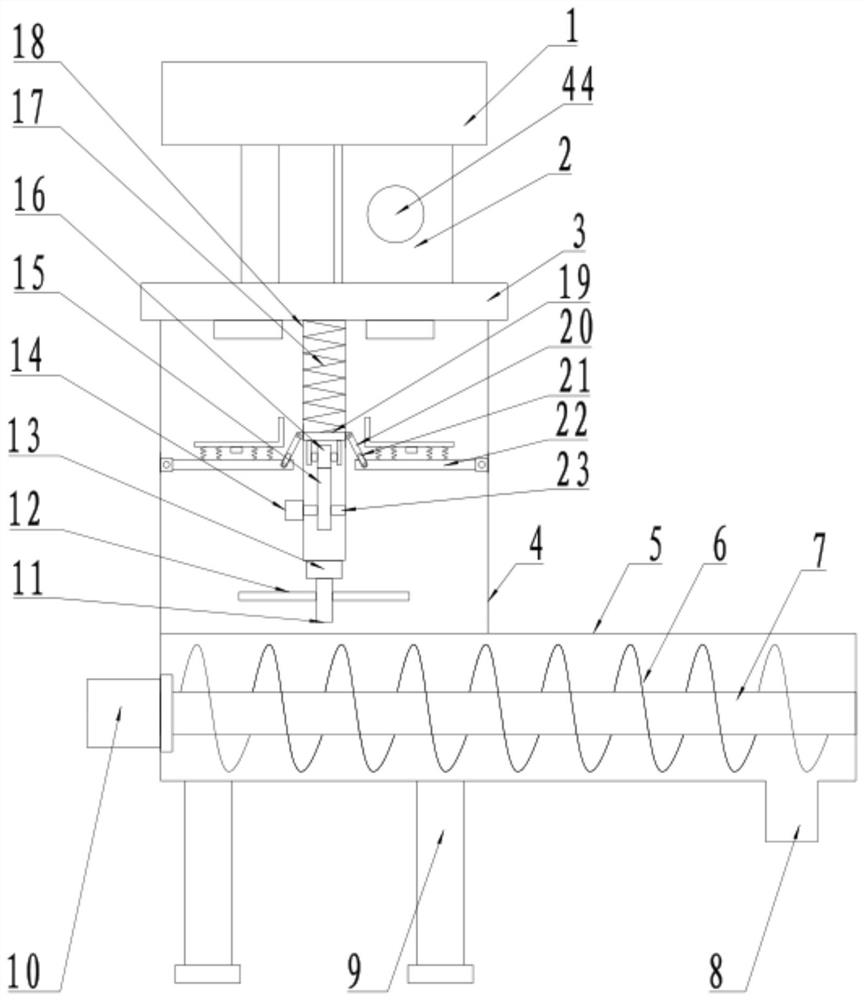

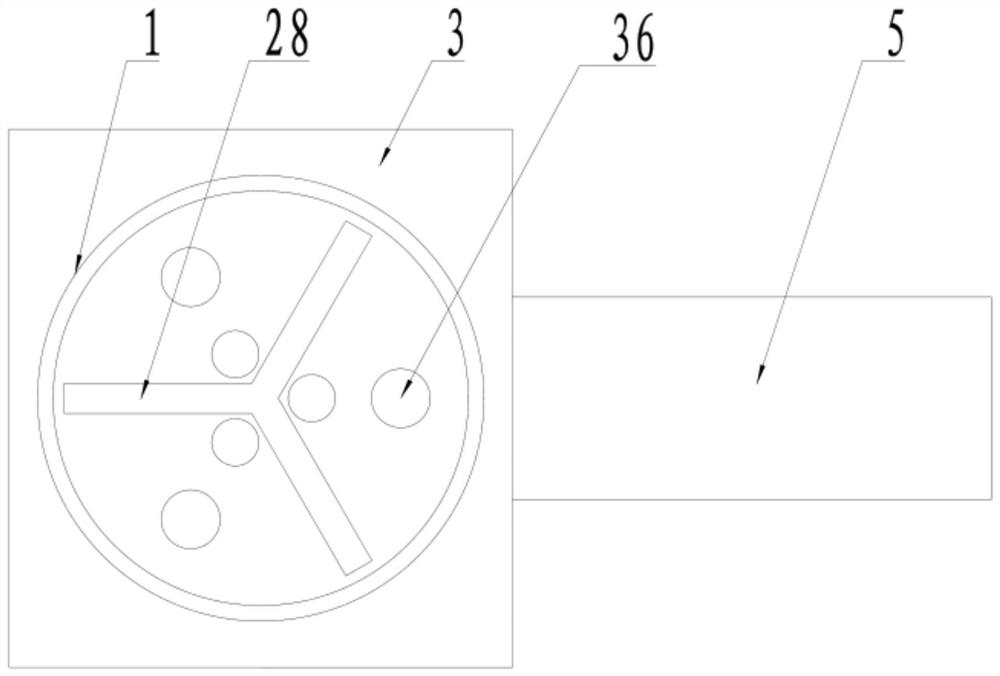

[0025] see Figure 1-7 , a blanking device for mechanical equipment, comprising a collection tank 1, the installation column 27 is rotatably connected in the collection tank 1, and the bottom of the collection tank 1 on the axial side of the installation column 27 is fixedly connected to the first motor 37, the first The output shaft of a motor 37 is fixedly connected to the mounting column 27, and the top side of the mounting column 27 is fixedly connected to the bearing rod 28 at equal intervals, and the two sides of the bottom of the bearing rod 28 are fixedly connected to the scraper 29, and the bearing rod 28 between the scraper 29 The bottom is rotatably connected to the rotating roller 30, and there are two rotating rollers 30. The bottom of the collecting tank 1 is provided with a feeding hole 36, which corresponds to the bottom of the scraper 29 on both sides of the bottom of the carrying rod 28, and the bottom of the feeding hole 36. The bottom of the collection tank...

Embodiment 2

[0031] see Figure 1-7 , the other content of this embodiment is the same as that of Embodiment 1, the difference is that: the rotating column 38 between the stirring blades 43 is fixedly connected to the stirring drum 39 at equal arc intervals, and the fourth spring 42 is fixedly connected to the stirring drum 39, The bottom of the fourth spring 42 is fixedly connected to the stirring column 40 , one side of the stirring column 40 passes through the mixing drum 39 , and the end is fixedly connected to the cleaning block 41 .

[0032] During the implementation of the present invention, by adding materials to be used in the collecting tank 1, driven by the first motor 37, the bearing rod 28 on the mounting column 27 drives the scraper 29 to move, and at the same time, the fifth motor 32 drives the rotation The roller 30 rotates, and the two rotating rollers 30 rotate in the opposite direction under the action of the transmission gear 31, conveying the material between the two s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com