Wear-resistant efficient horizontal centrifugal sand pump and working method thereof

A wear-resistant and high-efficiency technology, applied in the field of centrifugal pumps, can solve the problems of low safety performance, high viscosity of the conveying fluid, poor conveying effect, etc., and achieve the effect of increasing the response to serious leakage, high equipment circulation speed, and not easy to leak to the outside world.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

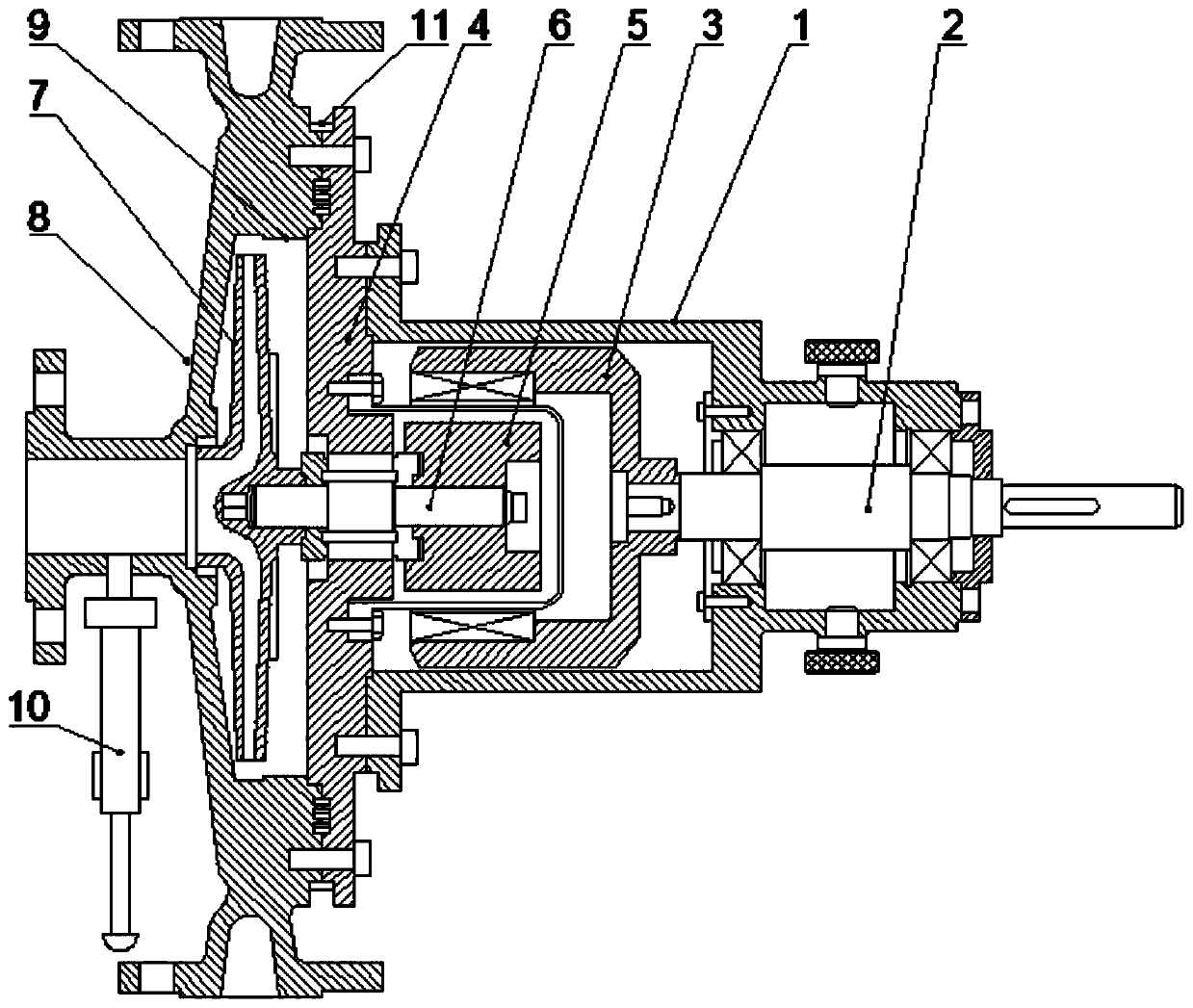

[0037] Such as figure 1 A wear-resistant high-efficiency horizontal centrifugal sand pump shown includes: pump casing 1, motor shaft 2, outer magnetic rotor 3, spacer sleeve 4, inner magnetic rotor 5, linkage shaft 6, impeller 7, end cover 8 and Wear-resistant layer 9, the pump casing 1 is provided with a motor shaft 2, one end of the motor shaft 2 is connected with an outer magnetic rotor 3, and the outer magnetic rotor 3 is arranged in the pump casing 1, and the outer magnetic rotor 3 A spacer 4 is arranged inside, and the spacer 4 is fixedly connected with the pump casing 1. An inner magnetic rotor 5 is arranged inside the spacer 4. One end of the inner magnetic rotor 5 is connected with a linkage shaft 6. The linkage shaft 6. An impeller 7 is provided at one end away from the inner magnetic rotor 3. An end cover 8 is provided outside the impeller 7. The end cover 8 is fixedly connected to the spacer sleeve 4. A gap is provided between the end cover 8 and the spacer sleeve ...

Embodiment 2

[0052] Such as figure 1 A wear-resistant high-efficiency horizontal centrifugal sand pump shown includes: pump casing 1, motor shaft 2, outer magnetic rotor 3, spacer sleeve 4, inner magnetic rotor 5, linkage shaft 6, impeller 7, end cover 8 and Wear-resistant layer 9, the pump casing 1 is provided with a motor shaft 2, one end of the motor shaft 2 is connected with an outer magnetic rotor 3, and the outer magnetic rotor 3 is arranged in the pump casing 1, and the outer magnetic rotor 3 A spacer 4 is arranged inside, and the spacer 4 is fixedly connected with the pump casing 1. An inner magnetic rotor 5 is arranged inside the spacer 4. One end of the inner magnetic rotor 5 is connected with a linkage shaft 6. The linkage shaft 6. An impeller 7 is provided at one end away from the inner magnetic rotor 3. An end cover 8 is provided outside the impeller 7. The end cover 8 is fixedly connected to the spacer sleeve 4. A gap is provided between the end cover 8 and the spacer sleeve ...

Embodiment 3

[0054] Such as figure 1 A wear-resistant high-efficiency horizontal centrifugal sand pump shown includes: pump casing 1, motor shaft 2, outer magnetic rotor 3, spacer sleeve 4, inner magnetic rotor 5, linkage shaft 6, impeller 7, end cover 8 and Wear-resistant layer 9, the pump casing 1 is provided with a motor shaft 2, one end of the motor shaft 2 is connected with an outer magnetic rotor 3, and the outer magnetic rotor 3 is arranged in the pump casing 1, and the outer magnetic rotor 3 A spacer 4 is arranged inside, and the spacer 4 is fixedly connected with the pump casing 1. An inner magnetic rotor 5 is arranged inside the spacer 4. One end of the inner magnetic rotor 5 is connected with a linkage shaft 6. The linkage shaft 6. An impeller 7 is provided at one end away from the inner magnetic rotor 3. An end cover 8 is provided outside the impeller 7. The end cover 8 is fixedly connected to the spacer sleeve 4. A gap is provided between the end cover 8 and the spacer sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com