Filtering recovery device for magnetic material processing waste liquor and filtering recovery method therefor

A technology for magnetic materials and processing waste liquid, which is applied in the field of filtration and recovery device and filtration and recovery device for magnetic material processing waste liquid, can solve the problems of low recovery rate and difficult cleaning of waste liquid, and achieves high waste recovery rate and convenient and quick cleaning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

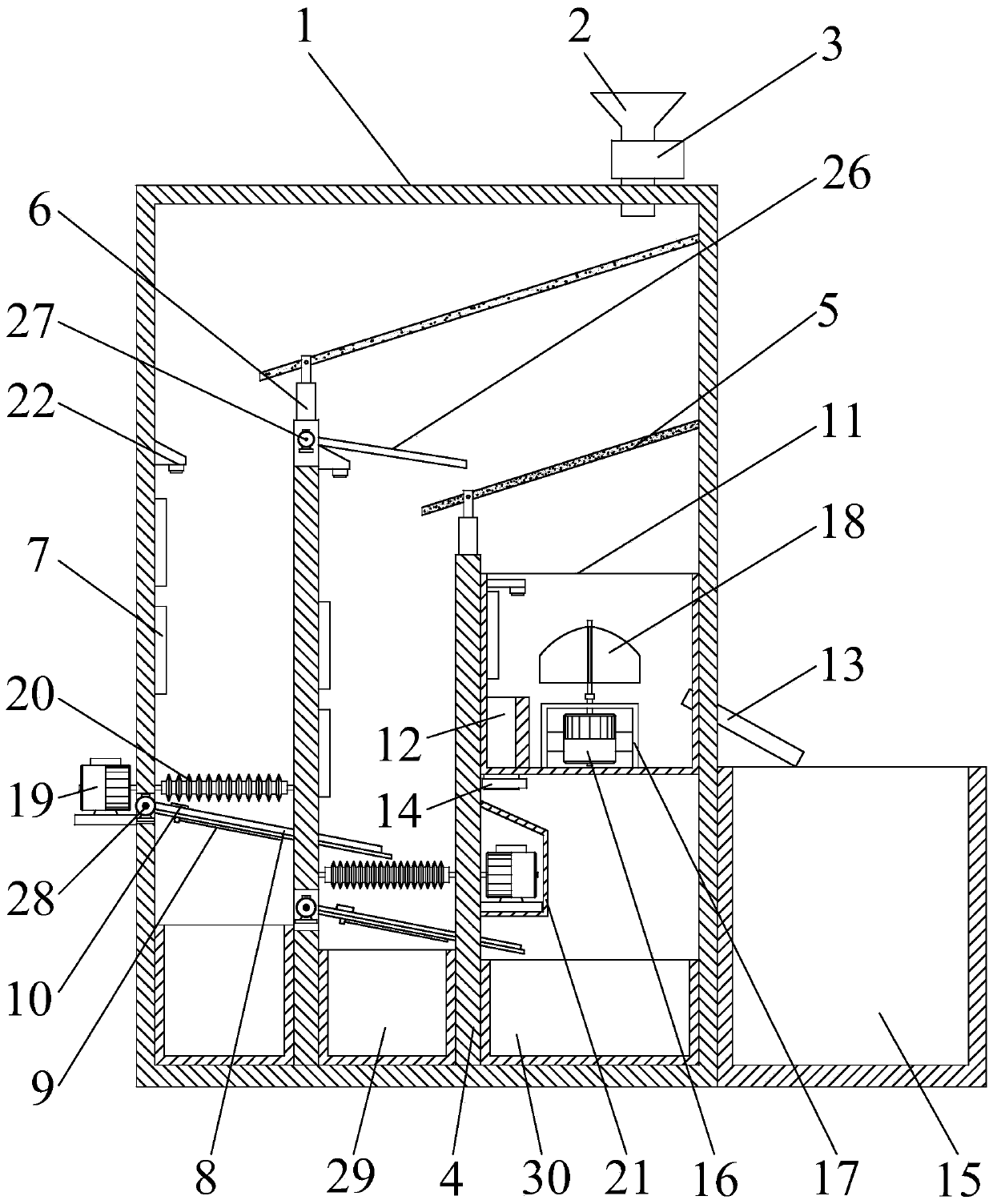

[0064] see figure 1 as well as figure 2 , This embodiment provides a device for filtering and recovering magnetic material processing waste liquid, which can filter the waste liquid generated during the production and processing of magnetic materials and recover the magnetic part therein. Wherein, the filter recovery device includes filter bucket 1, liquid inlet funnel 2, liquid inlet valve 3, partition plate 4, filter assembly, electromagnet 7, crushing assembly, transmission assembly, separation mechanism, sedimentation tank 15, detection assembly and control The device, in this embodiment, may also include a second slide plate 26, an angle adjustment assembly, a collection bucket one 29 and a collection bucket two 30.

[0065] Filter barrel 1 can be placed vertically on the ground, also can be placed directly in other equipment, can also be placed on other processing platforms. Filter bucket 1 can adopt square bucket, also can adopt the bucket body of shape, can also dir...

Embodiment 2

[0084] This embodiment provides a device for filtering and recovering magnetic material processing waste liquid, which adds the control function of the controller on the basis of Embodiment 1. Wherein, when the accumulation amount exceeds the preset accumulation amount, the controller also calculates the difference between the accumulation amount and the preset accumulation amount, and adjusts the expansion and contraction of the expansion member 6 with reference to a preset difference-expansion amount comparison table. quantity. There is a one-to-one data correspondence between the difference value and the stretch amount in the difference value-stretch amount comparison table.

[0085] Certainly, in some embodiments, the controller is also used to judge whether the corresponding relationship between the amount of expansion and contraction of the telescopic member 6 and the difference satisfies the data corresponding relationship, and then judge whether the accumulation amount...

Embodiment 3

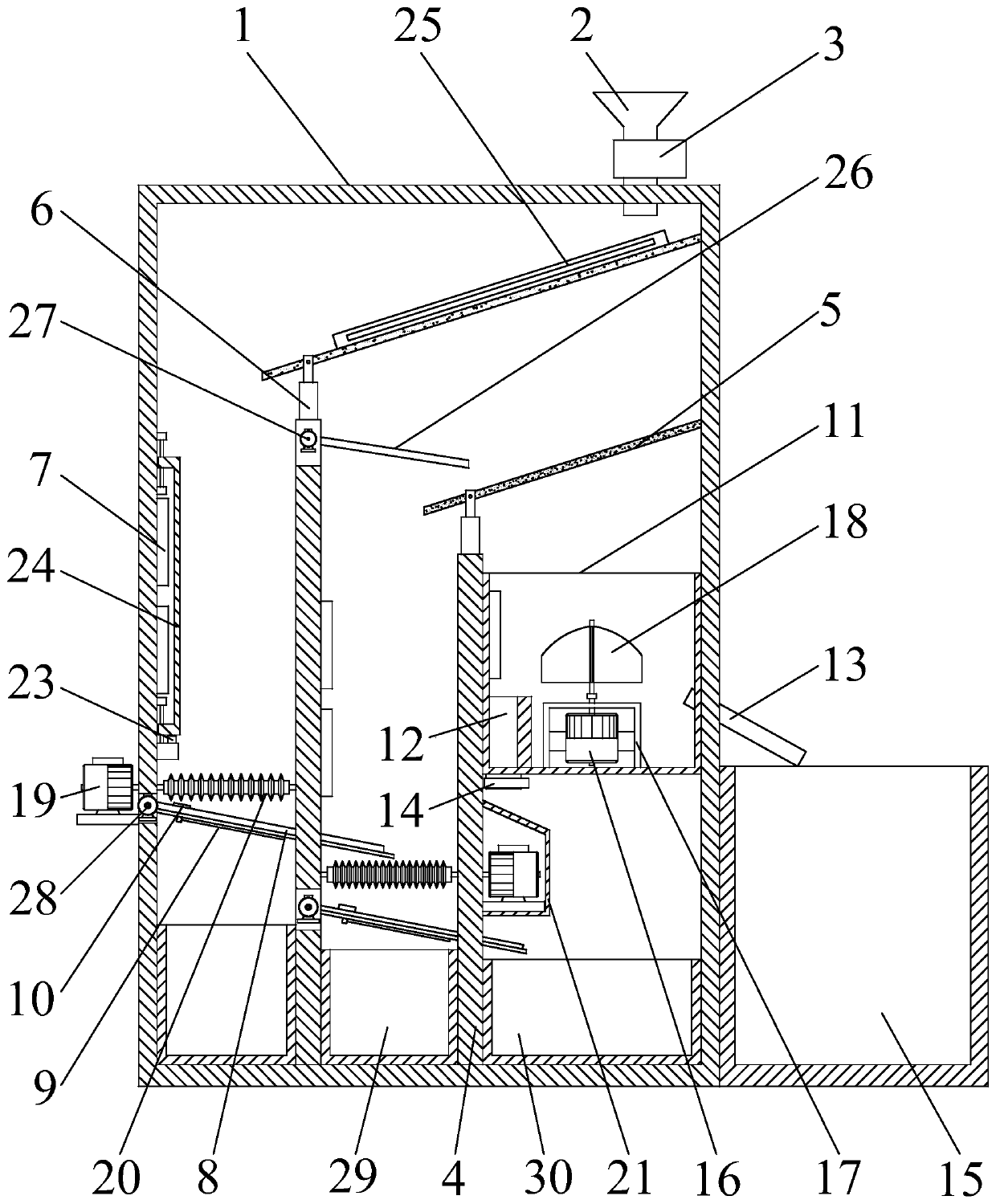

[0088] see image 3 , This embodiment provides a filter and recovery device for magnetic material processing waste liquid, which is similar to the filter and recovery device for magnetic material processing waste liquid in Embodiment 1, except that the structure of the detection mechanism is different. In this embodiment, the detection mechanism includes a second load cell 23 , a sliding cover 24 and a second photoelectric sensor 25 .

[0089] The number of the second load cell 23 and the sliding cover 24 is at least three, and there is a one-to-one correspondence between the second load cell 23 , the sliding cover 24 and the filtering space. Each sliding cover 24 is installed in the corresponding filtering space, and slides along the gravitational direction of the magnetic waste. Each group of electromagnets 7 is installed in the corresponding sliding cover 24 , and the generated magnetic field can attract the magnetic waste in the corresponding filtering space on the corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com