Adjustable quantitative filtering and screening machine for flour

A screening machine and flour technology, applied in the direction of sieve, solid separation, grille, etc., can solve the problems of blockage of sieves, increase the time required for screening, difficult to disperse evenly, etc., and achieve the effect of convenient adjustment and fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

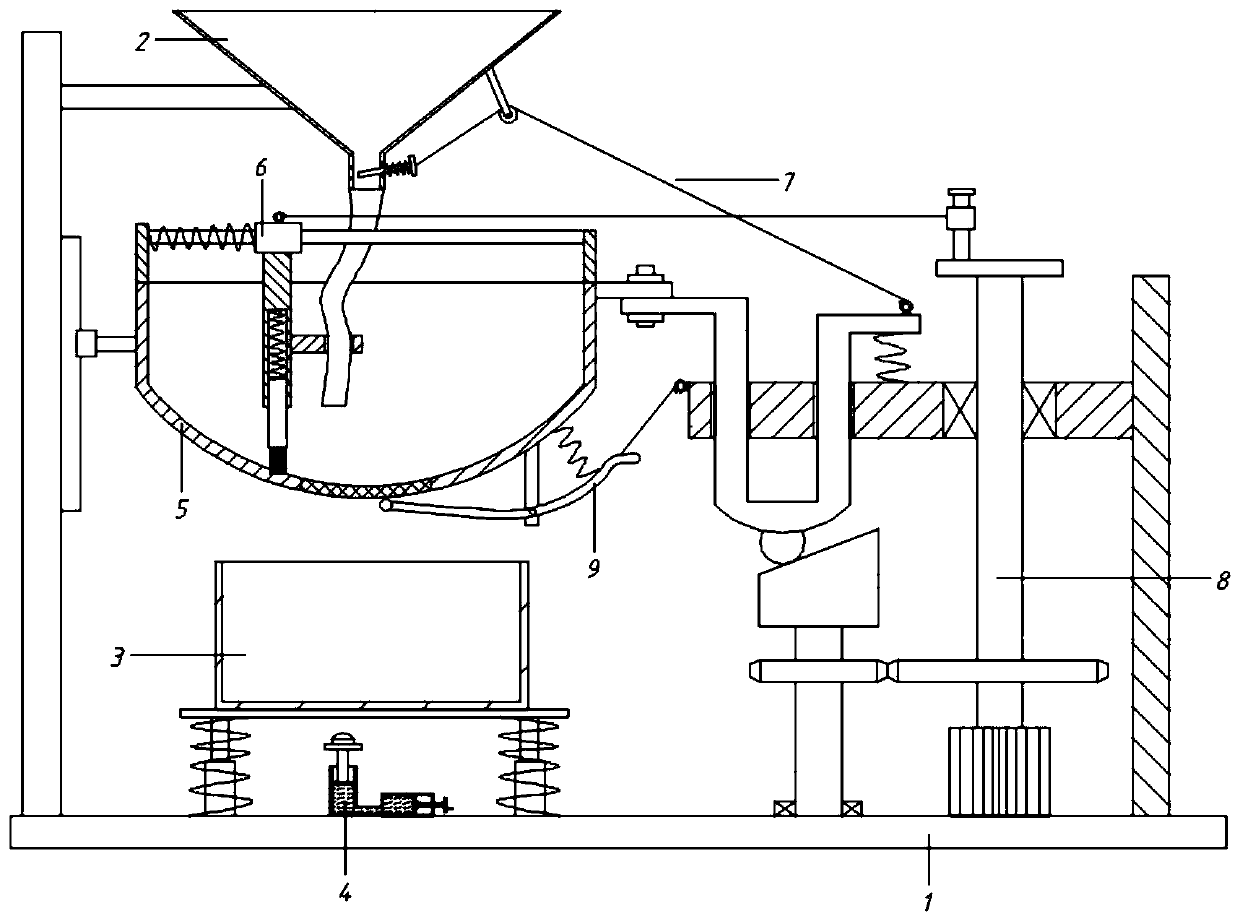

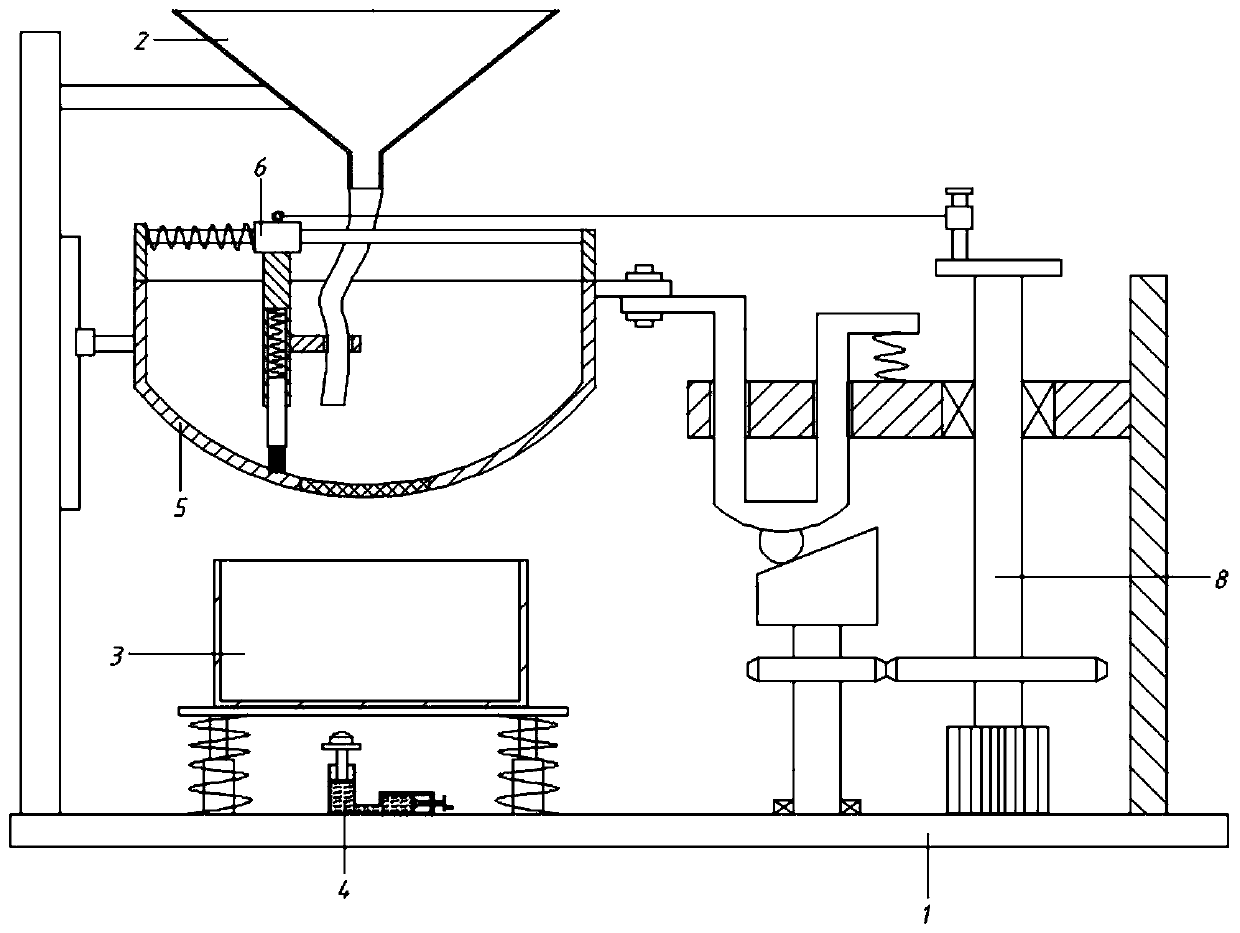

[0062] With reference to the accompanying drawings, an adjustable quantitative filtering and screening machine for flour includes a frame 1, a driving assembly 8, a feeding assembly 2, a screening assembly 5, a sweeping assembly 6, a receiving assembly 3 and a braking assembly 4;

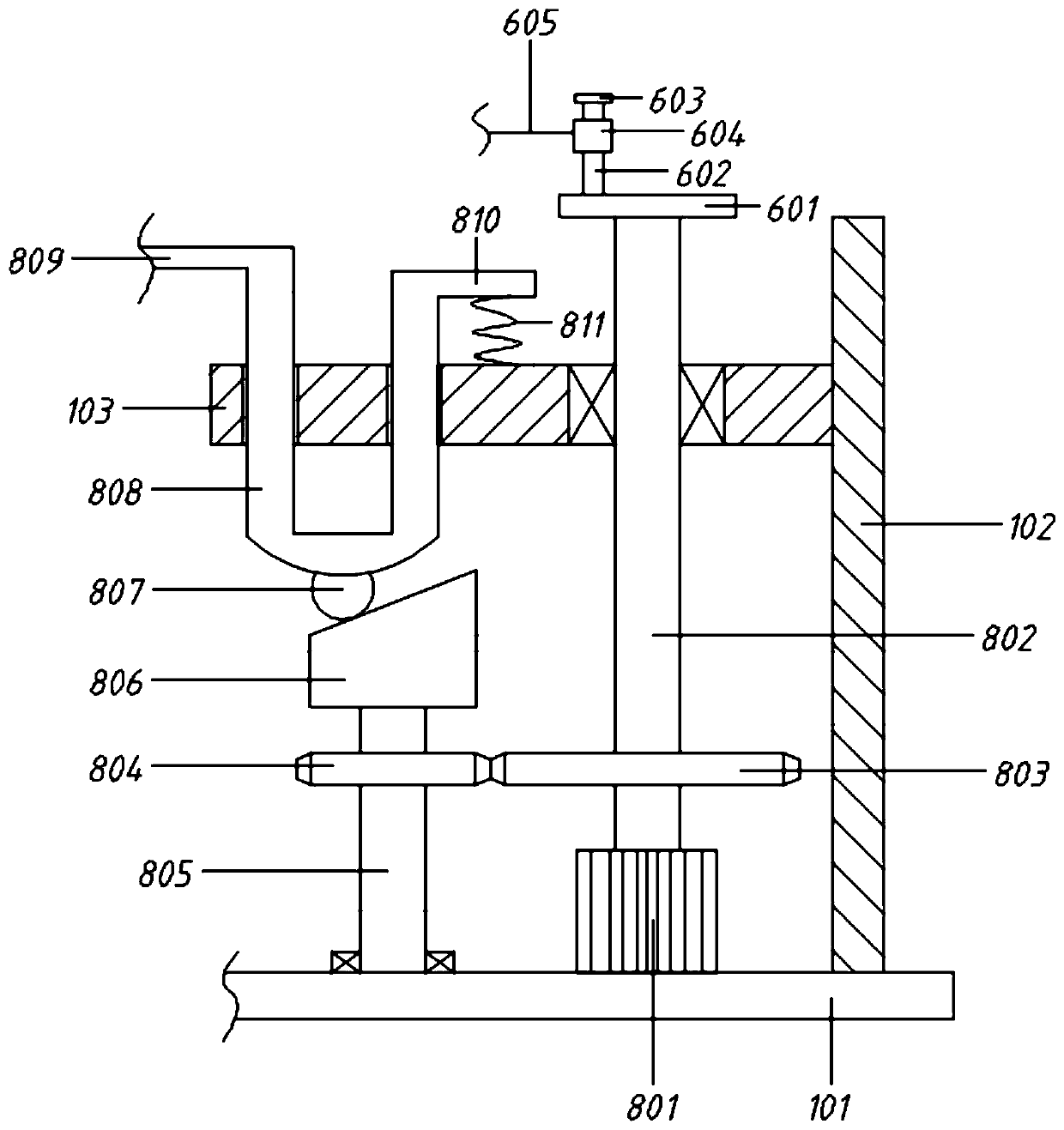

[0063] The frame 1 includes a base 101, a right side plate 102, a guide plate 103 and a left side plate 104, the right side plate 102 is fixed on the right end of the base 101, the left side of the upper section of the right side plate 102 is connected with a guide plate 103, and the left side plate 104 is fixed on the base The left end of 101; the right part of the base 101 is provided with a drive assembly 8, and the top of the drive assembly 8 passes through the guide plate 103; the left part of the base 101 is provided with a material receiving assembly 3, and the brake assembly 4 is arranged below the material receiving assembly 3; the material receiving assembly 3 A screening assembly 5 is arra...

Embodiment 2

[0065] With reference to the accompanying drawings, an adjustable quantitative filtering and screening machine for flour includes a frame 1, a driving assembly 8, a feeding assembly 2, a screening assembly 5, a sweeping assembly 6, a receiving assembly 3 and a braking assembly 4;

[0066] The frame 1 includes a base 101, a right side plate 102, a guide plate 103 and a left side plate 104, the right side plate 102 is fixed on the right end of the base 101, the left side of the upper section of the right side plate 102 is connected with a guide plate 103, and the left side plate 104 is fixed on the base The left end of 101; the right part of the base 101 is provided with a drive assembly 8, and the top of the drive assembly 8 passes through the guide plate 103; the left part of the base 101 is provided with a material receiving assembly 3, and the brake assembly 4 is arranged below the material receiving assembly 3; the material receiving assembly 3 A screening assembly 5 is arra...

Embodiment 3

[0088] On the basis of embodiment 2,

[0089] Also includes blanking assembly 7; blanking assembly 7 includes No. 2 tether ring 701, No. 2 guide wheel 704, No. 2 stay rope 703, push-pull plate 705, partition 706 and No. 1 spring 707;

[0090] The second tether ring 701 is fixed on the top of the right connecting plate 810; the second guide wheel 704 is fixed on the right side of the feeding hopper 201; the partition 706 is inserted into the feed pipe 202 from the right, and the right end of the partition 706 is fixedly connected with a push-pull plate 705 A No. 1 spring 707 is connected between the push-pull plate 705 and the outer wall of the material guide tube 202;

[0091] Specifically, while the U-shaped frame 808 moves up and down, it also drives the No. 2 stay rope 703 to move, and cooperates with the No. 1 spring 707 to make the push-pull plate 705 drive the partition 706 to move, and intermittently block or open the material guide tube 202 to realize Intermittent fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com