Lead-acid storage battery coloring paste stirring device for preventing blowhole

A lead-acid battery and stirring device technology, applied in mixers with rotating stirring devices, foam dispersion/prevention, dissolution, etc., can solve problems such as poor battery appearance, reduce product appearance defect rate, avoid pores, structure novel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

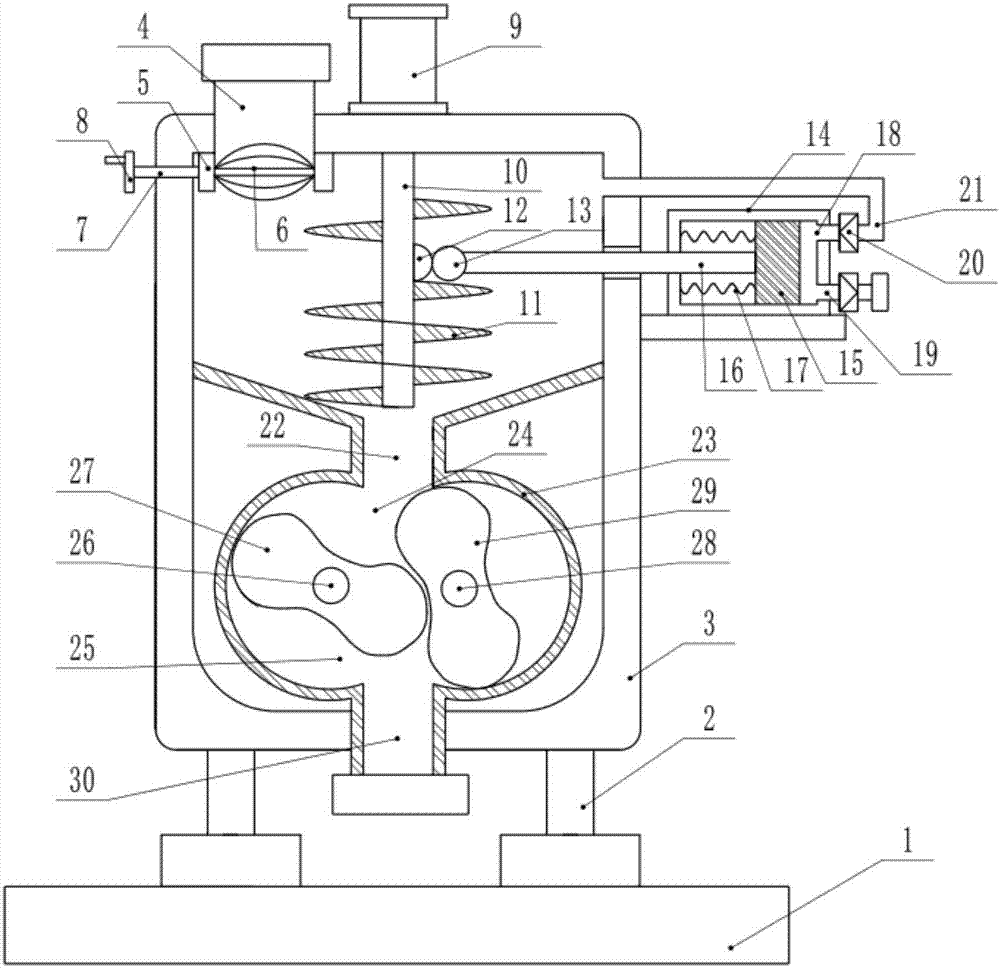

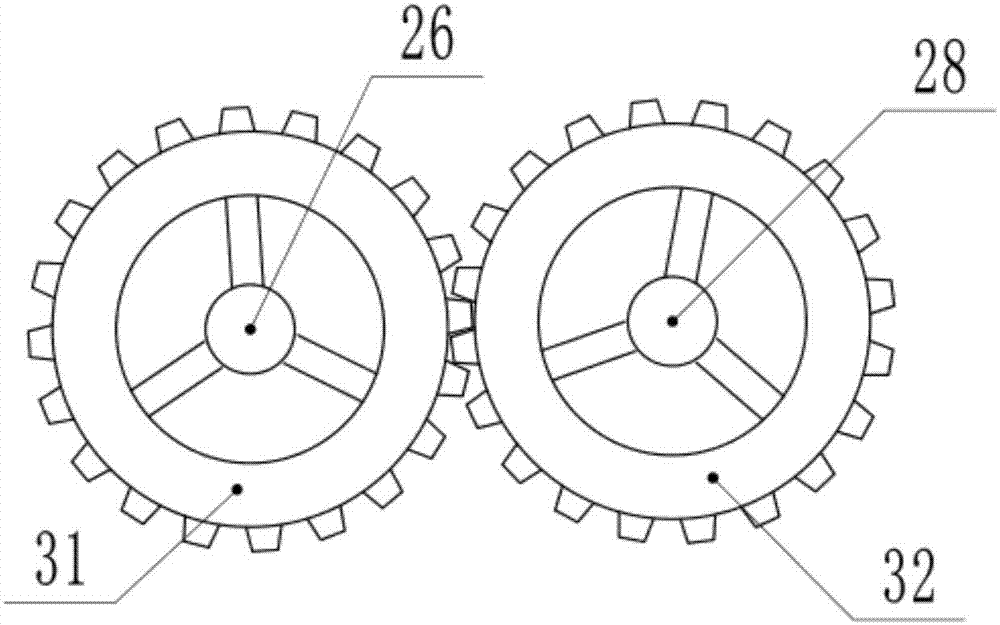

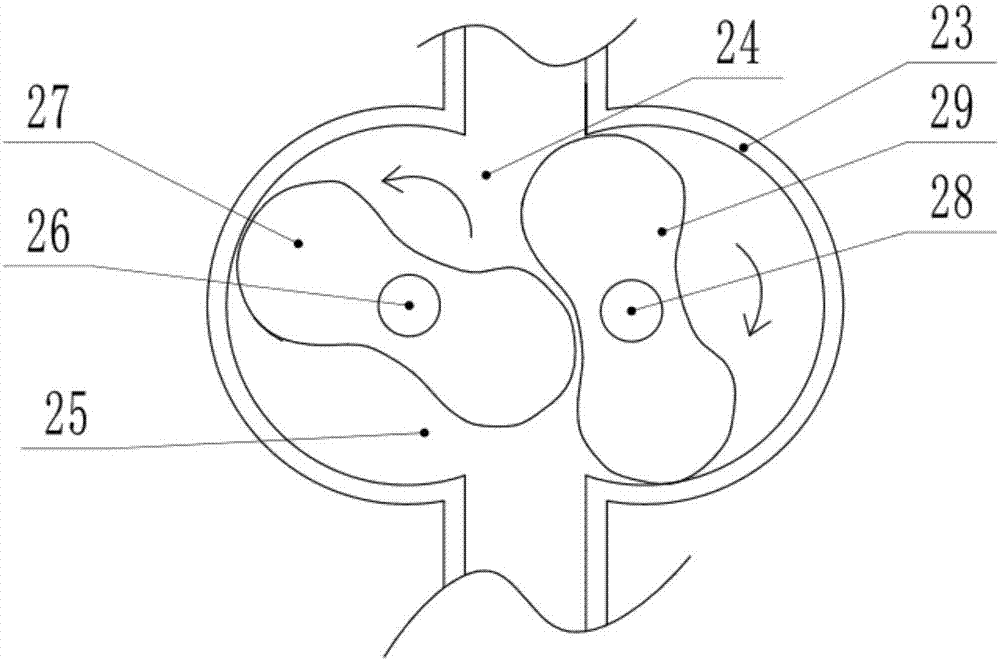

[0020] see Figure 1-3 , a lead-acid battery color glue stirring device for preventing air holes, comprising a stirring box 3, a feed runner 6, a stirring motor 9, an air extraction device 14 and an extruding device 23, and the left and right sides of the upper surface of the base 1 are welded and fixed A support column 2 is installed, and the upper end of the support column 2 is fixedly welded with a stirring box 3. The upper left side of the stirring box 3 has a feed port 4, and a feed runner 6 is arranged below the feed port 4, and the feed runner 6 rotates. Installed on the connection plate 5, the connection plate 5 is fixed on the upper inner wall of the mixing box 3 by screws, the feed runner 6 is fixedly connected to the rotating shaft 7, and the rotating shaft 7 is horizontal to the left and passes through the casing of the mixing box 3 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com