Pressure-reducing heating and drying device

A drying device, decompression heating technology, applied in the direction of heating device, heating to dry solid materials, drying solid materials, etc., can solve the problems of difficult decompression drying treatment and heating drying treatment, cumbersome drying treatment process, and long time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In the following description, for purposes of illustration rather than limitation, specific details, such as specific system architectures, interfaces, and techniques, are set forth in order to provide a thorough understanding of the present invention.

[0021] The decompression heating and drying device described in the following embodiments of the present invention is used to carry out decompression heating and drying treatment on the coated color filter (Colorfilter, CF) substrate, so that the coated color filter has photoresist The thin film of the agent is fully developed, so that the next step can be processed.

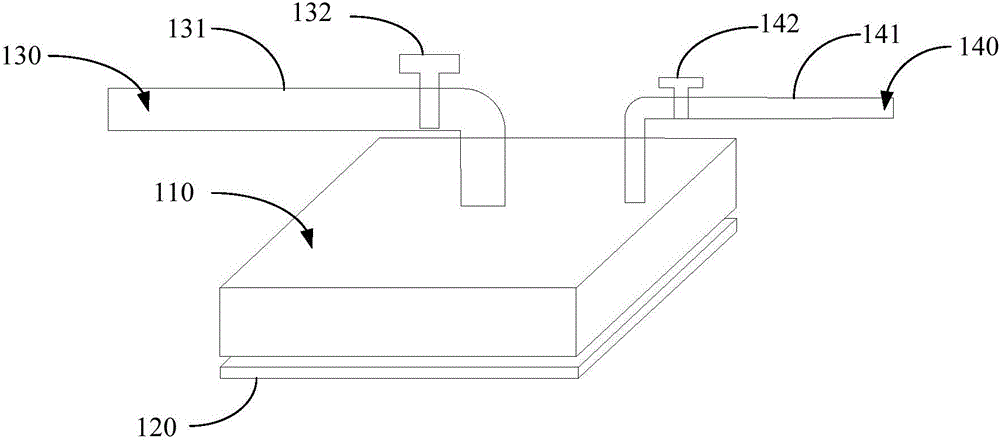

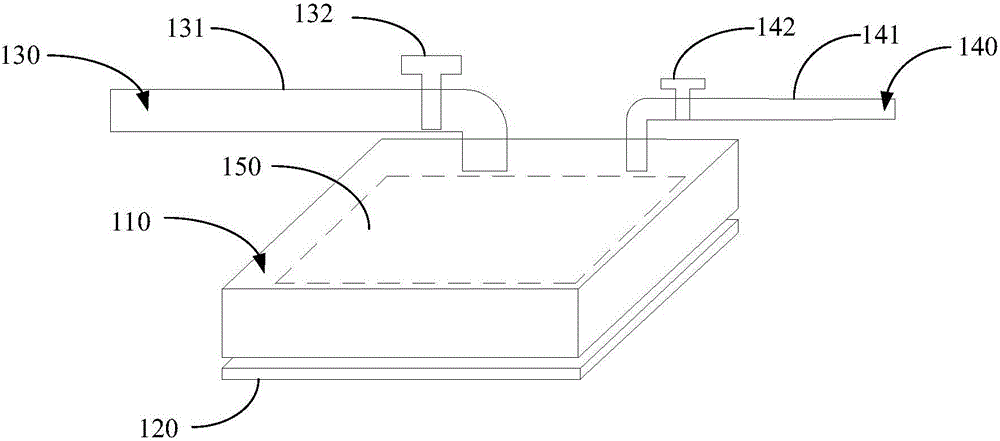

[0022] see figure 1 , figure 1 It is a structural schematic diagram of an embodiment of the vacuum heating drying device of the present invention. The decompression heating and drying device in this embodiment includes a chamber 110 , a carrying mechanism (not shown in the figure), a heating mechanism 120 , a decompression mechanism 130 , and an air pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com