Haydite prepared from dregs of oil shale, and preparation method

A technology of oil shale slag and ceramsite, applied in applications, household utensils, clay products, etc., can solve the problems of low added value, acidification, and hazards to residents' health, reduce drying shrinkage and deformation, accelerate the drying process, and improve The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-13

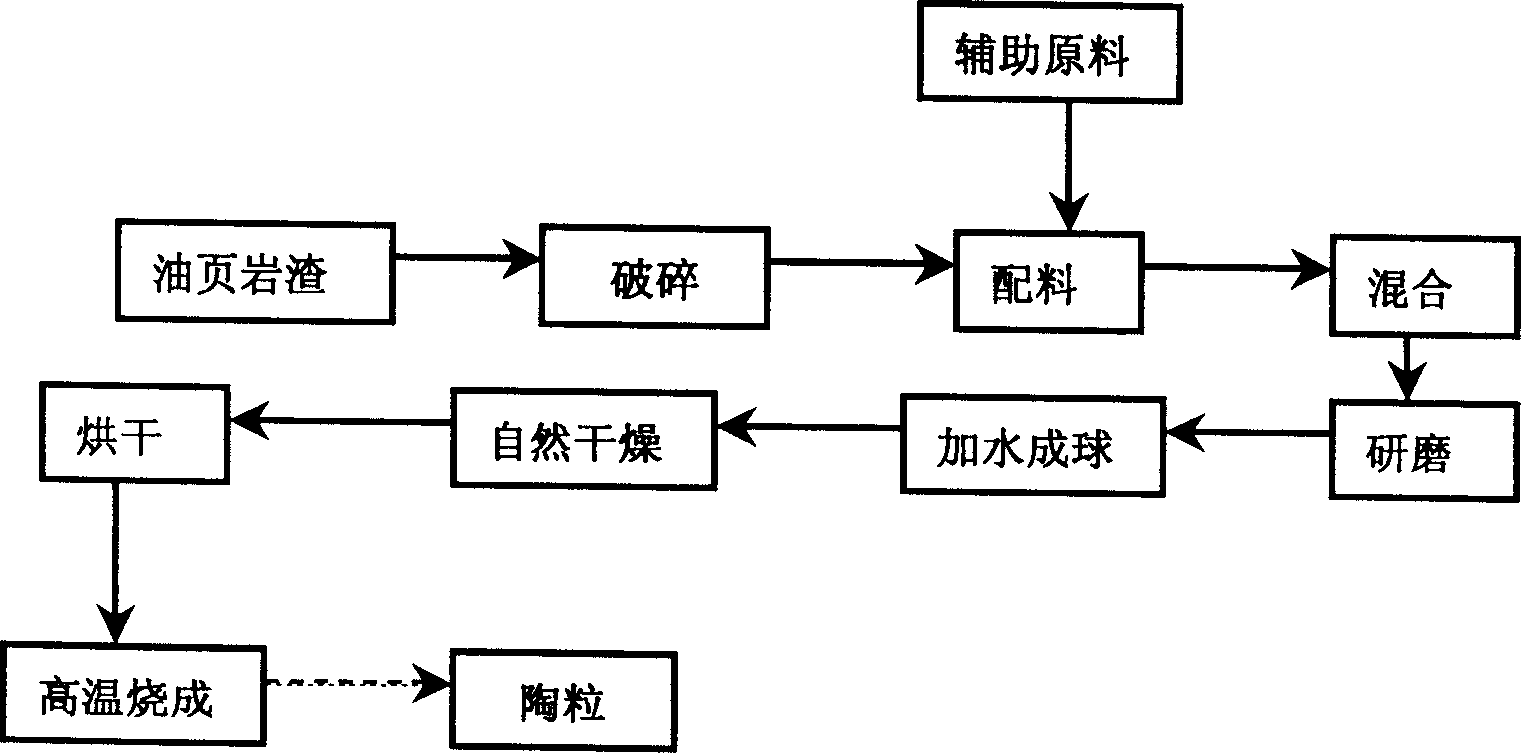

[0028] The present invention uses the ceramsite prepared by oil shale slag and the embodiment 1-13 of preparation method thereof, and its method step is:

[0029] (1) Crush the raw materials separately, mix them and grind them finely, add water to make balls; the specific steps are:

[0030] a. Crushing the raw materials into powder respectively;

[0031] b. Raw material allocation: Weigh the required amount of raw materials according to the formula;

[0032] c. Mixing material: Pour the prepared mixed material into the fast grinder, grind for 3-5 minutes, and finally make the particle size of the mixed material meet the following requirements: the particle size is less than 0.1mm, and the weight of particles with a particle size greater than 0.05mm It accounts for 25-35% of the total weight of raw materials, and the weight of particles with a particle diameter less than 0.05mm accounts for 65-75% of the total weight of raw materials.

[0033] d. Forming balls: Method 1, add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com