Method for treating oily waste by using conversion agent, conversion agent and preparation method thereof

A technology for transforming agents and oils, applied in the field of transforming agents and their preparation, can solve the problems of difficult disposal of hazardous wastes, waste of resources and energy, few industrialization projects, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

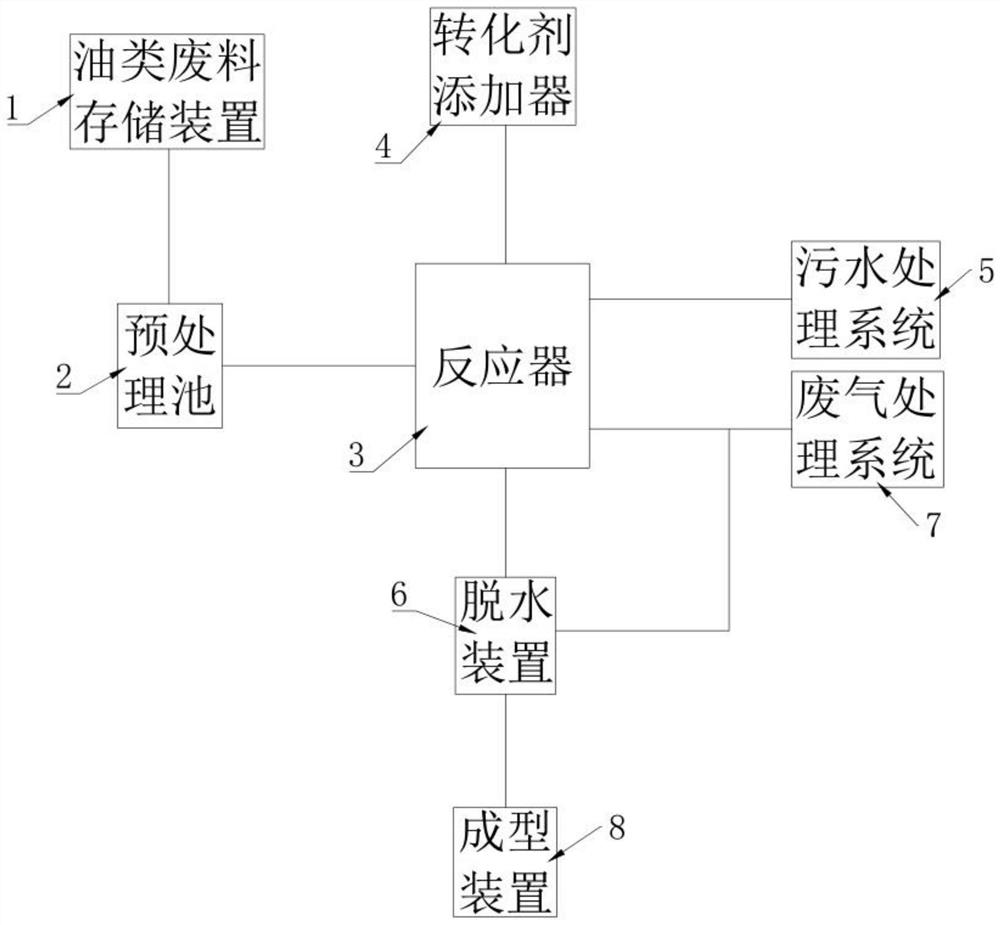

Method used

Image

Examples

Embodiment 1

[0038] The conversion agent in this embodiment includes a functional compounding agent and a catalytic assistant. Among them, the functional compounding agent includes the following components and raw materials in weight percent: 9-17% of titanium acyl ion, 18-23% of amide polyether, 5-13% of polyethylene polyamine, and 5-8% of dimethylglyoxime , ethanol 28-35% and ethyl acetate 16-23%. The catalytic promoter includes the following components and raw materials in parts by weight: tetrahydrofurfuryl alcohol 10-15%, trichloroethane 13-18%, pyrrolidone 10-16%, 4-chlorophenol 22-25%, diethanolamine 20- 25% and ammonia 9-17%.

[0039] Preferably, in the functional compounding agent, the weight ratio of titanium acyl ion, amide polyether, polyethylene polyamine, dimethylglyoxime, ethanol and ethyl acetate is 17:18:13:8:16:28. Preferably, in the catalyst promoter, the weight ratio of tetrahydrofurfuryl alcohol, trichloroethane, pyrrolidone, 4-chlorophenol, diethanolamine and ammoni...

Embodiment 2

[0042] The preparation method of the transforming agent of this embodiment comprises the following steps: according to 9-17% of titanium acyl ion, 18-23% of amide polyether, 5-13% of polyethylene polyamine, 5-8% of dimethylglyoxime, 28% of ethanol -35% and ethyl acetate 16-23% components and parts by weight are mixed as raw materials, and the mixed raw materials are stirred evenly at a temperature of 50-60 DEG C to obtain a functional compounding agent. According to the composition and weight of 10-15% tetrahydrofurfuryl alcohol, 13-18% trichloroethane, 10-16% pyrrolidone, 22-25% 4-chlorophenol, 20-25% diethanolamine and 9-17% ammonia water The raw materials are mixed according to the number of parts, and the mixed raw materials are stirred evenly at normal temperature to obtain the catalytic promoter.

[0043] Wherein, the functional compounding agent and the catalyst auxiliary agent are prepared and stored separately, so as to be taken separately. In specific applications, ...

Embodiment 3

[0045] In this embodiment, the method for applying conversion agent to treat oily waste comprises the following steps:

[0046] Oily waste is transferred to the reactor.

[0047] Add the functional compounding agent and stir at normal temperature for 5-15 minutes, then stop stirring and stand for 15-25 minutes to react, and then discharge the precipitated sewage; wherein, the dosage of the functional compounding agent is 0.1-10%.

[0048]Adding a catalyst booster, heating to 110-130 degrees centigrade, maintaining a constant temperature and stirring for 15-25 minutes, completing dehydration and deodorization, and obtaining a converted product; wherein, the amount of the catalyst booster is 1-20%.

[0049] Preferably, before the oily waste is transferred into the reactor, the oily waste is filtered through a pretreatment tank.

[0050] Preferably, the functional compounding agent is added and stirred at room temperature for 10 minutes, then the stirring is stopped and the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com