Fluidized bed exhaust gas desulfurizing method and desulfurizing installation

A fluidized bed and flue gas technology, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve problems such as large system resistance, increased dust collector load, and large water consumption for desulfurization treatment, achieving low operating costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

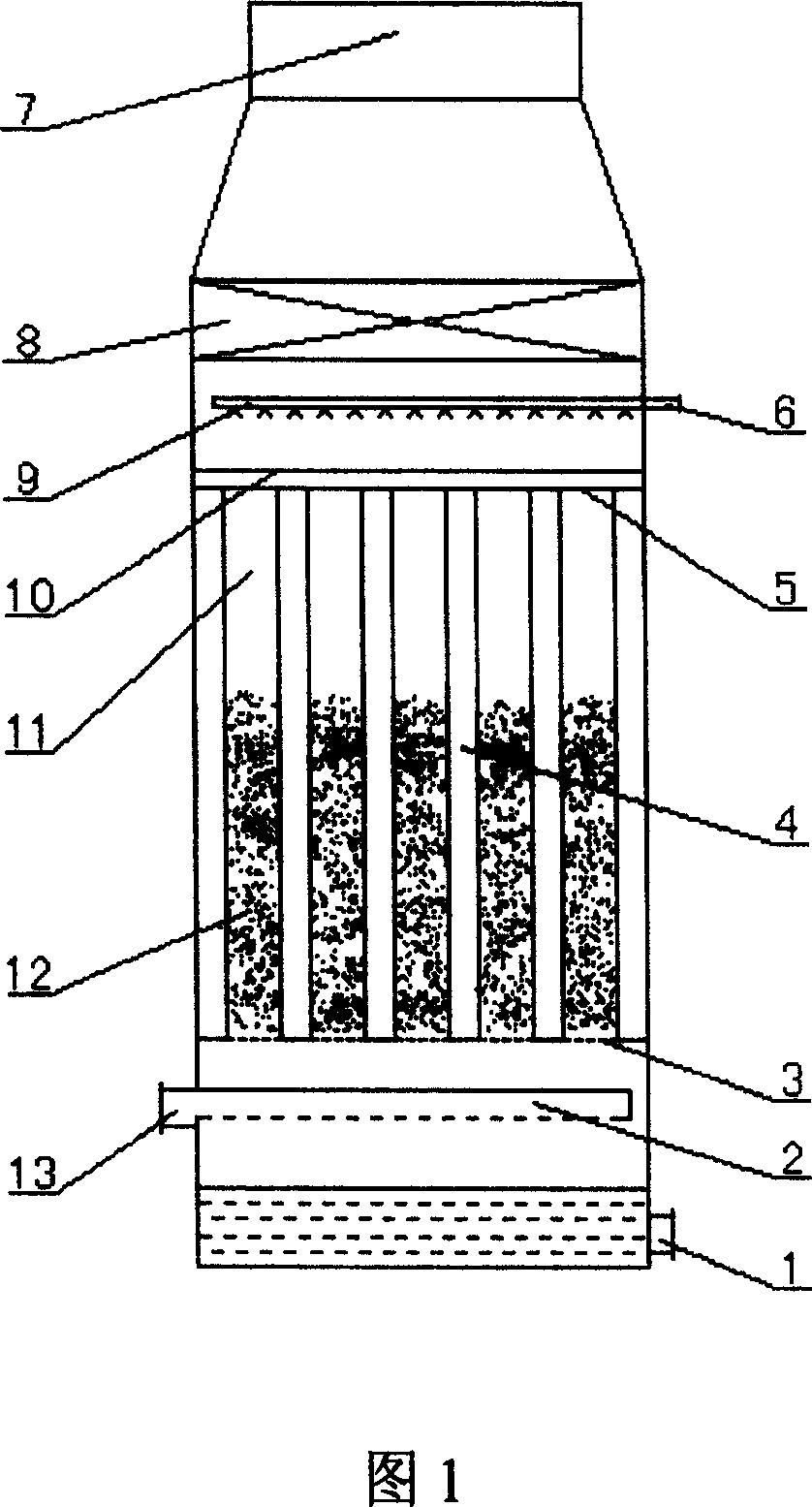

[0018] The structure of the fluidized bed desulfurization device is shown in Figure 1, including a fluidized bed desulfurization tower 4, an absorption liquid inlet 6 on the tower body, an absorption liquid outlet 1, a flue gas inlet 13, and a flue gas discharge channel 7, which are supported in the tower body A number of tubular absorbers 11 are vertically installed between the board 3 and the flower board 5, and filled with lightweight spherical packing 12 with a diameter of 18mm and made of PVC, and the filling height is 950mm; the spray device 9 is installed on the flower board 5 is connected to the absorption liquid inlet 6 on the tower body; the flow divider 2 connected to the flue gas inlet 13 is installed under the support plate 3; the absorption liquid outlet 1 is installed at the bottom of the tower body, and the flue gas discharge channel 7 is installed At the top of the tower body, a block 10 is installed on the flower plate 5 to prevent the light spherical filler 1...

Embodiment 2

[0022] The structure of the ebullating bed desulfurization device is the same as in Example 1, and the tubular absorber 11 is filled with lightweight spherical fillers 12 with a diameter of 20 mm and made of ABS, and the filling height is 200 mm; 2 The flue gas enters the tower from the lower flue gas inlet 13 of the fluidized bed desulfurization tower 4, and after being divided by the flow splitter 2, enters the tubular absorber 11 at a flow rate of 20m / s, and sprays the light spherical packing 12 into a boiling state ; The carbonamide absorbent with a concentration of 25% enters the tower from the absorption liquid inlet 6, and passes through the spray device 9 at a distance of 37m 3 / m 2 The spray density of h is sprayed down from the upper part of the fluidized bed desulfurization tower in the form of droplets, and contacts with the flue gas and packing to form a gas-liquid-solid three-phase high-speed collision, which strengthens the mass transfer coefficient and the SO i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com