Washing and blowing type washing rack

A cleaning rack and washing and blowing type technology, which is applied in the field of experimental instruments, can solve the problems of time-consuming and labor-intensive cleaning of experimental utensils, and achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

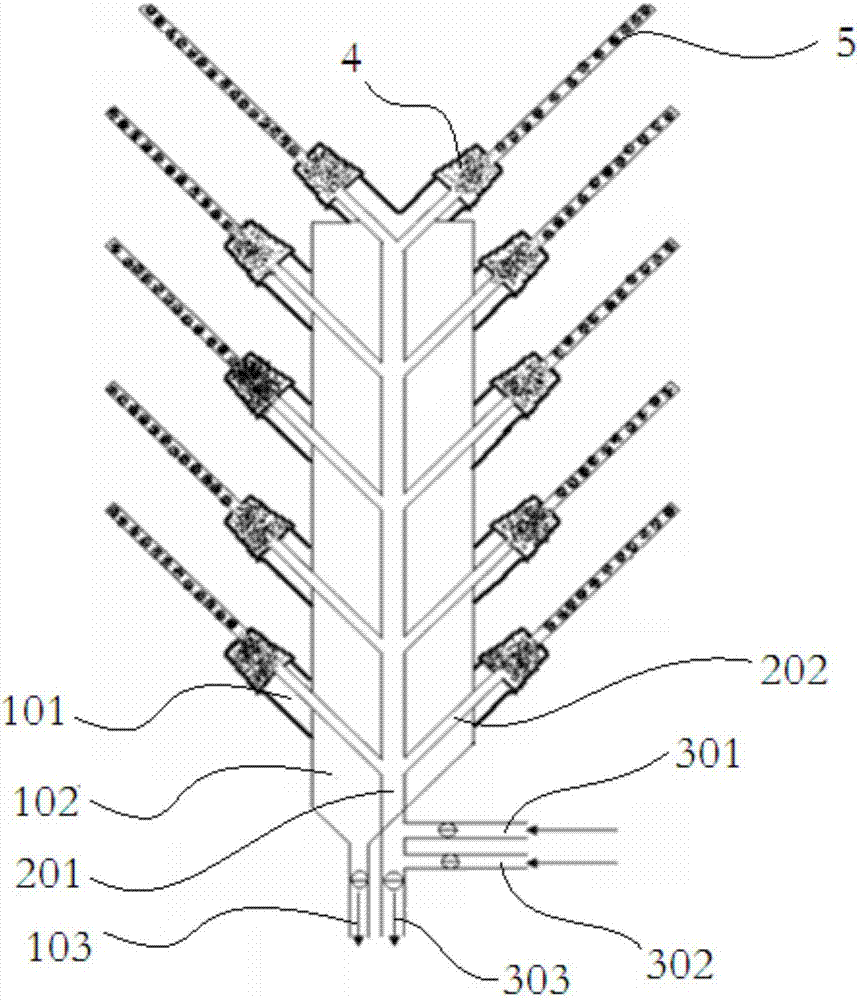

[0027] A washing and blowing type cleaning rack is characterized in that it includes a main body bracket 1, a built-in pipe 2, an external pipe 3, an external grinding port 4 and a hollow pipe 5.

[0028] The main body support 1 is composed of several main body branches 101 , a main body 102 and a valved waste liquid pipe 103 . The main body 102 is a hollow cylindrical structure. The main body branch 101 is connected to the outer wall of the main body 102, and the main body branch 101 is a cylindrical structure forming an acute angle with the horizontal plane and obliquely upward. The valved waste liquid pipeline 103 is a funnel-shaped structure, and the open end of the valved waste liquid pipeline 103 is connected to the bottom of the main body 102 .

[0029] The built-in pipeline 2 is located inside the main body bracket 1 , and the built-in pipeline 2 is composed of a common gas-liquid main pipeline 201 and several branch pipelines 202 . The branch pipeline 202 is connect...

Embodiment 2

[0038] Using the washing and blowing type cleaning rack in Example 1 to clean the experimental vessel requires the following steps:

[0039] 1) Close the valve pipeline 301 of the gas-liquid conveyor belt, the valve pipeline 302 of the cleaning fluid conveyor belt and the valve pipeline 303 of the cleaning fluid discharge belt;

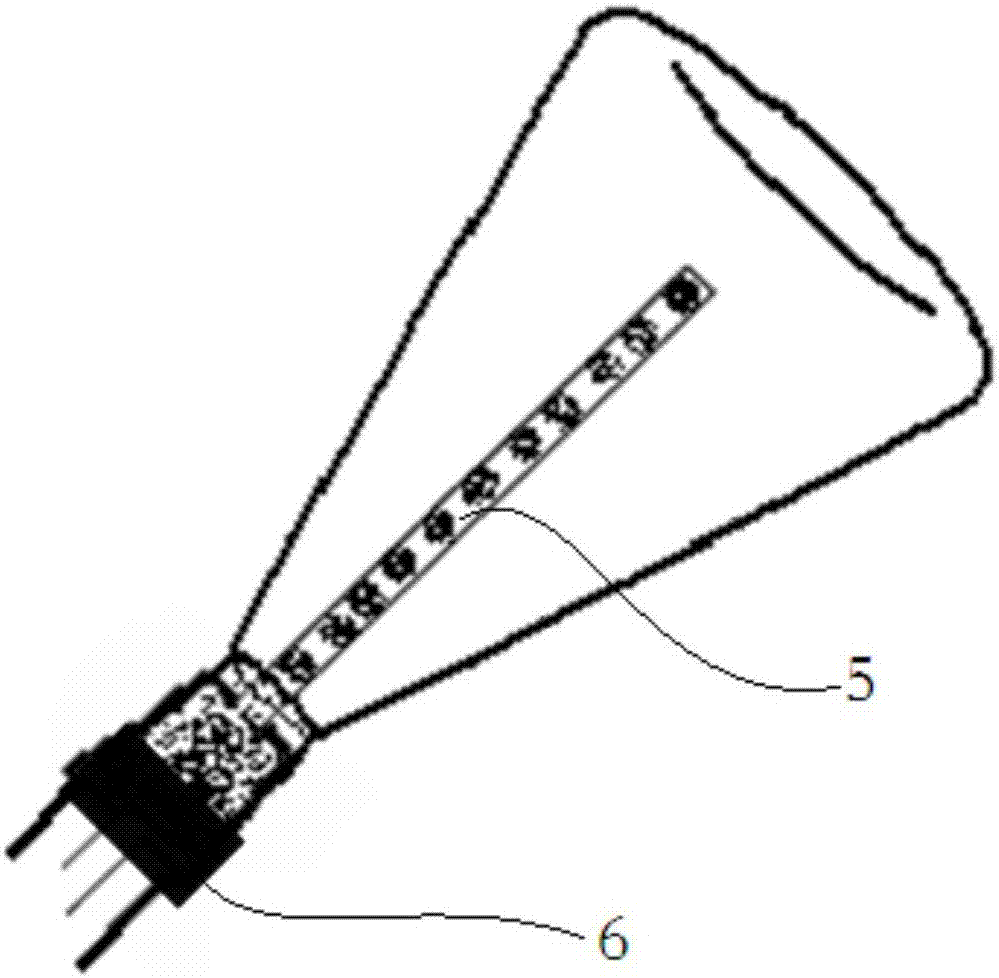

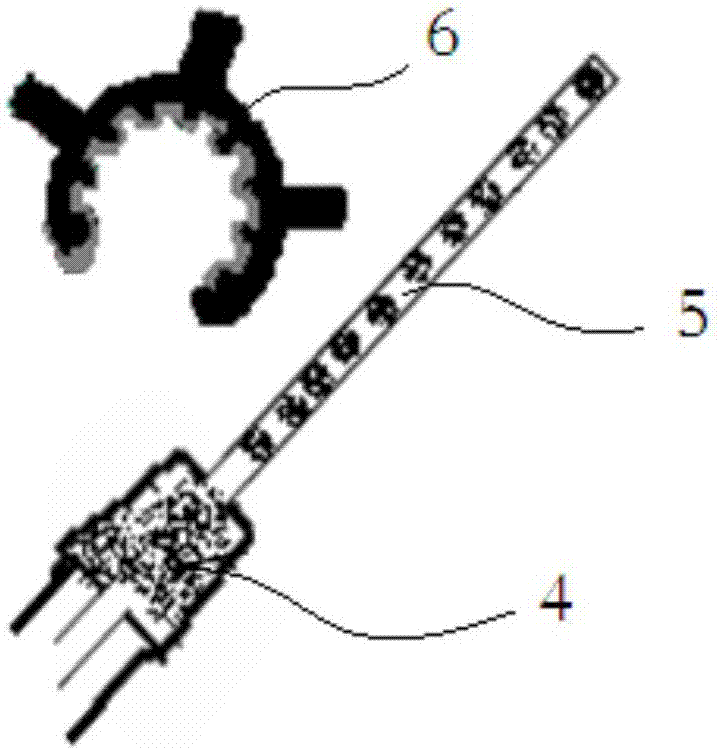

[0040] 2) Install the inner grinding mouth inside the mouth of the Erlenmeyer flask, such as Figure 4 Shown is the Erlenmeyer flask after the inner grinding mouth is installed; image 3 shown, and insert the hollow tube 5 into the outer grinding port 4; image 3 The adjacent short rods on the ferrule 6 outer wall in the middle are pinched so that the outer grinding mouth 4 and the bottleneck of the Erlenmeyer flask are fixedly connected. eventually get as figure 2 structure shown

[0041] 3) Open the waste liquid pipeline 103 with valve;

[0042] 4) Open the valve pipeline 302 of the cleaning liquid conveyor belt, and inject the cleaning liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com