Dewatered sludge aerobic fermentation device and technique

A dewatered sludge and aerobic fermentation technology, applied in sludge treatment, biological sludge treatment, etc., can solve the problem that personnel are greatly affected by site gas, operations are greatly affected by weather factors, and the bottom of the stack is easy to compact, etc. Problems, to achieve the effect of improving oxygen supply efficiency, reducing heat loss, and reducing blast volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1 A dewatered sludge aerobic fermentation device

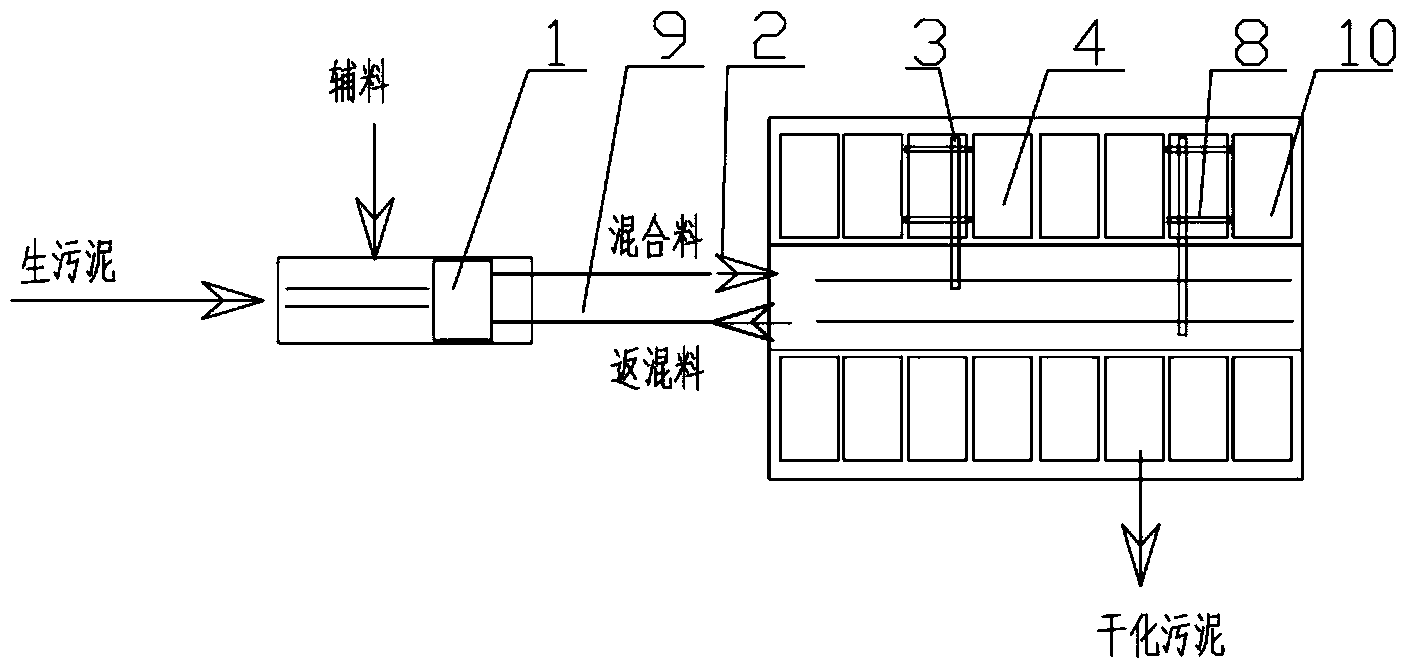

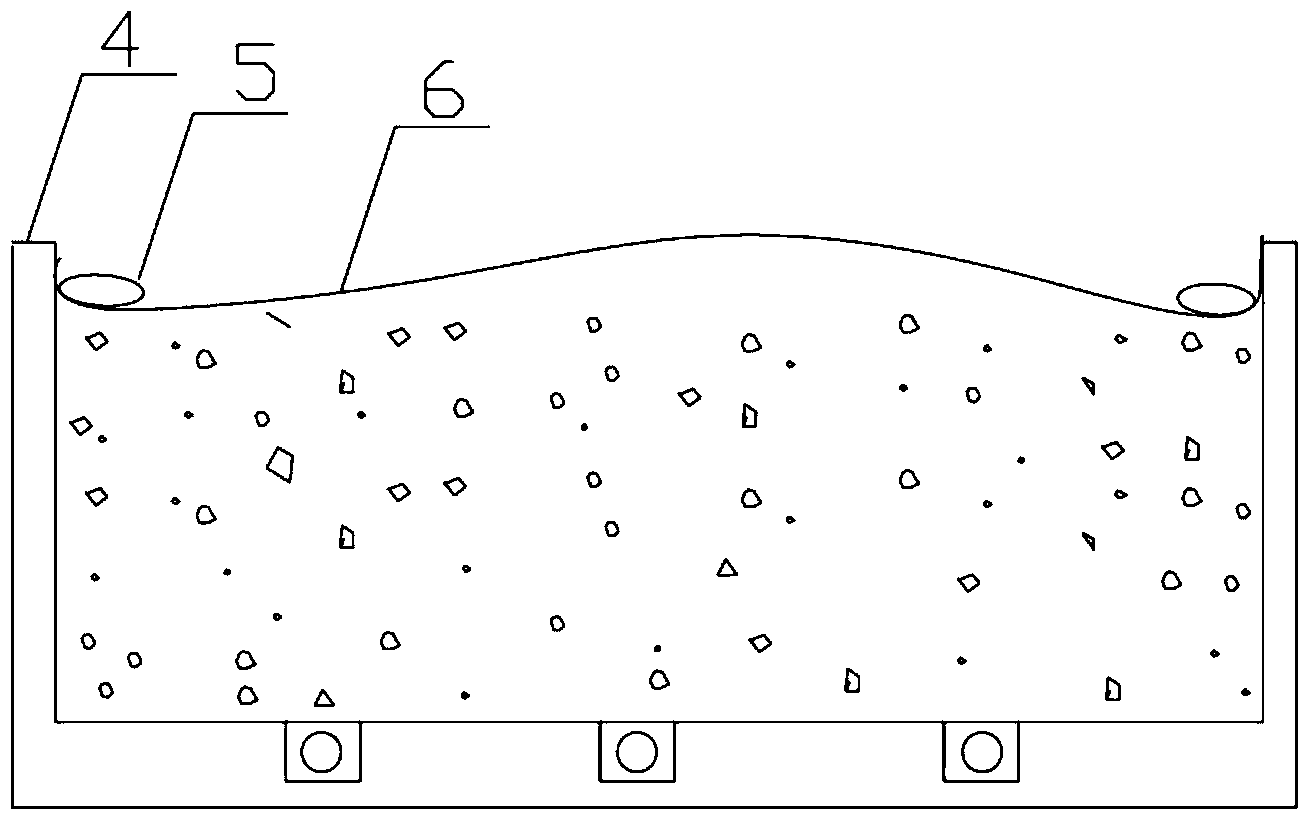

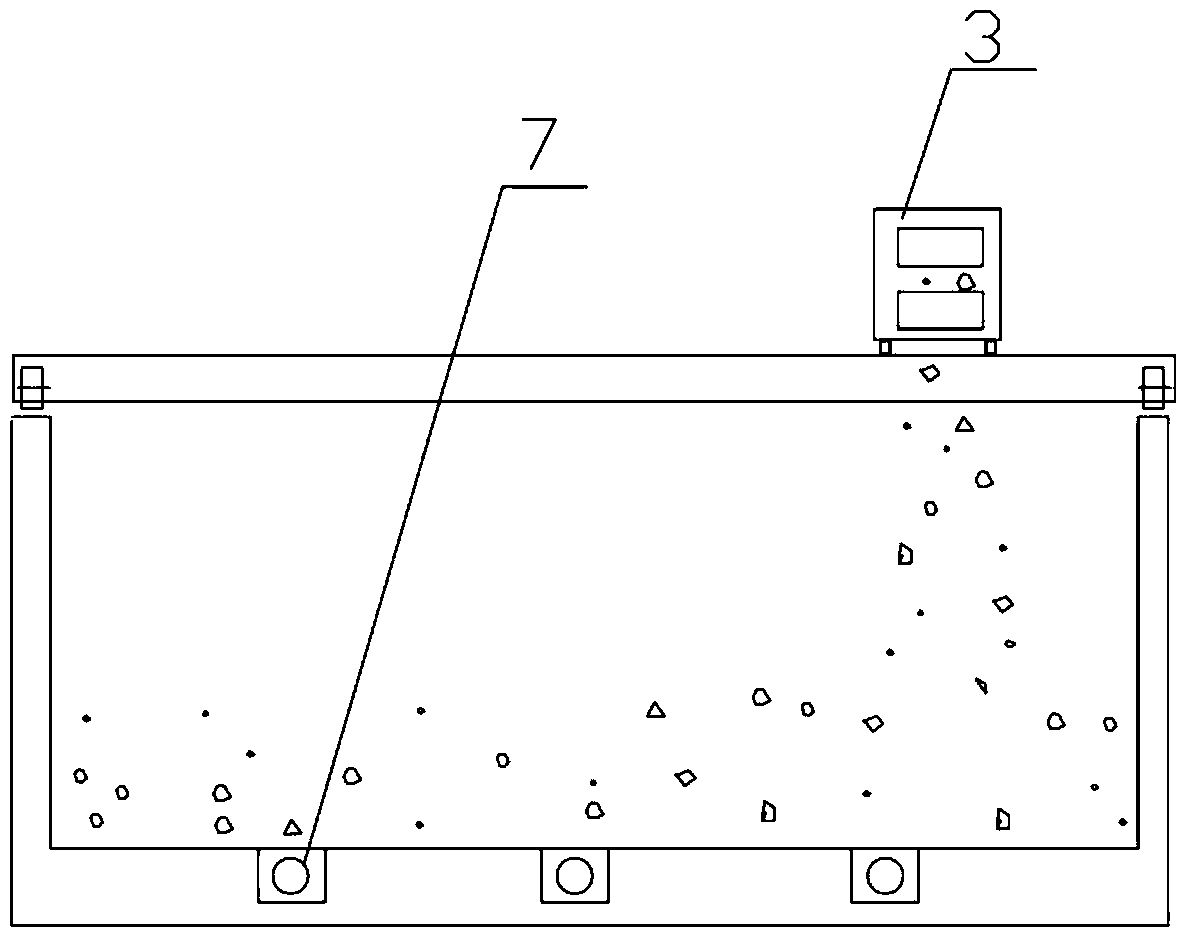

[0050] Such as Figure 1-3 As shown, a dewatered sludge aerobic fermentation device includes a mixing crusher 1 and a fermentation unit 4; wherein, the fermentation unit is composed of two rows of fermentation tanks, and two conveyor belts are arranged between the two rows of fermentation tanks 2, 9 and the automatic distributing machine 3 and automatic reclaimer 8 arranged thereon; wherein, each row of fermenter group can be divided into primary fermenter group and secondary fermenter group 10; wherein, the fermenter Lay the sheet 6 on the surface of the sheet, and compact it with a ballast at the peripheral seam of the sheet.

[0051] Wherein, the number of the fermentation tanks is 16, and there are 14 primary fermentation tanks, and the rest are secondary fermentation tanks. The bottom of each fermenter is provided with 3 ventilation pipe grooves, and perforated ventilation pipe 7 is established in it, and...

Embodiment 2

[0060] Example 2 A dewatered sludge aerobic fermentation device

[0061] The same as the fermentation device described in Example 1, the difference is that the number of the fermentation tanks is 14, and there are 10 primary fermentation tanks, and the rest are secondary fermentation tanks. The bottom of each fermenter is provided with 2 ventilation pipe grooves, and perforated ventilation pipe is arranged in it, and the width and depth of the ventilation pipe grooves are 19cm, and the diameter of the ventilation pipe is 9cm. The spacing of the ventilation pipes and the spacing of the holes on the pipes are both 0.8m.

Embodiment 3

[0062] Example 3 A dewatered sludge aerobic fermentation device

[0063] The same as the fermentation device described in Example 1, the difference is that the number of the fermentation tanks is 10, and there are 8 primary fermentation tanks, and the rest are secondary fermentation tanks. The bottom of each fermenter is provided with 4 vent pipe grooves, and perforated vent pipe is arranged in it, and the width and depth of the vent pipe grooves are 21cm, and the diameter of the vent pipe is 11cm. The spacing of the ventilation pipes and the spacing of the holes on the pipes are both 1.2m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com