Chemical material drying equipment for preventing material accumulation

A material accumulation and drying equipment technology, applied in the direction of drying solid materials, non-progressive dryers, lighting and heating equipment, etc., can solve the problems of long drying time, polluted samples, and affecting material quality, etc., and achieves convenient use and simple structure , The effect of speeding up the drying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

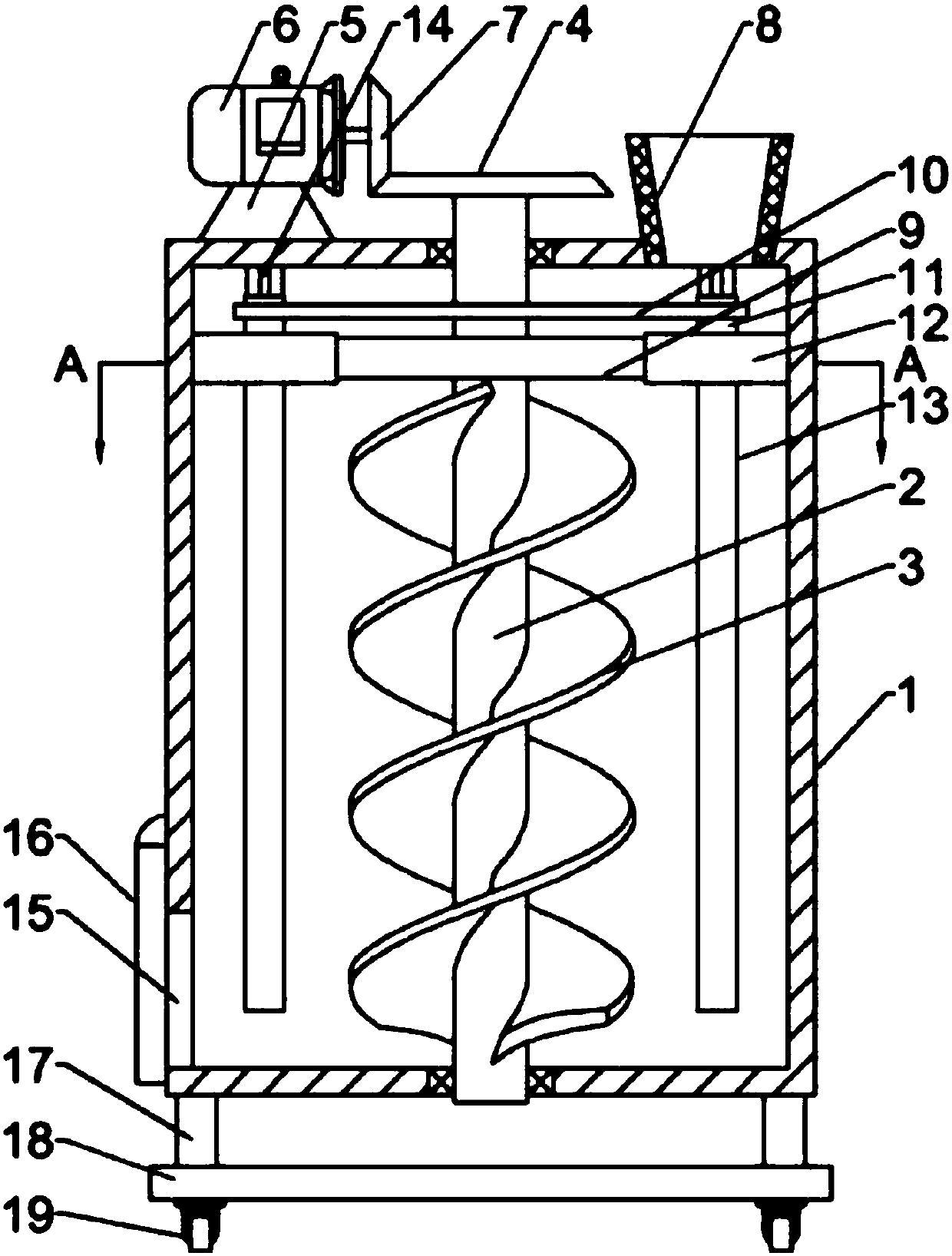

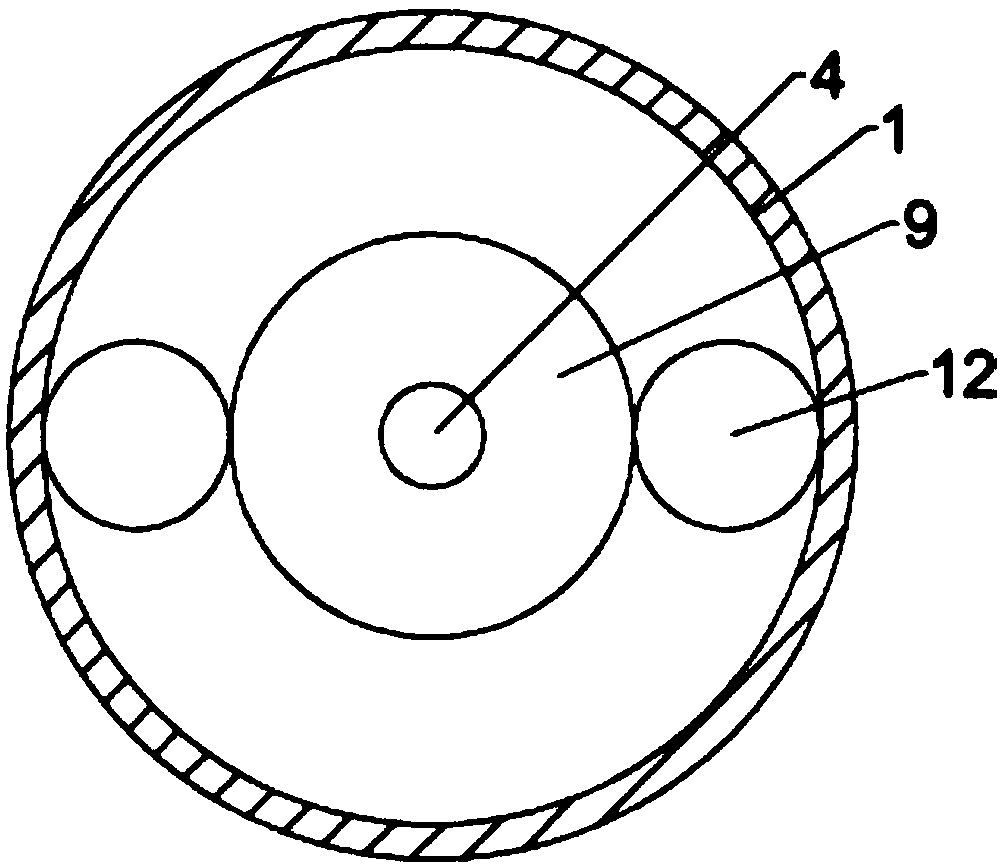

[0018] see Figure 1-2 , a chemical material drying equipment for preventing material accumulation, comprising a housing 1, the middle part of the housing 1 is rotatably connected with a main rotating shaft 2 through bearings, the outer side of the main rotating shaft 2 is fixedly connected with a spiral lifting blade 3, and the top of the main rotating shaft 2 A driven bevel gear 4 is fixedly connected, a motor base 5 is fixedly connected to the top left of the housing 1, and a motor 6 is fixedly connected above the motor base 5. The output end of the motor 6 is fixedly connected with a driving bevel gear 7, and the driving bevel gear 7 is connected with the The driven bevel gear 4 is meshed;

[0019] When in use, the chemical raw materials to be dried are placed inside the housing 1, and then the motor 6 can be started for stirring. The rotation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com