Rice cleaning device for energy-saving food processing

A food processing and cleaning device technology, applied in energy-saving measures, cleaning methods using liquids, applications, etc., can solve the problems of low cleaning efficiency of rice and failure to meet market demand, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

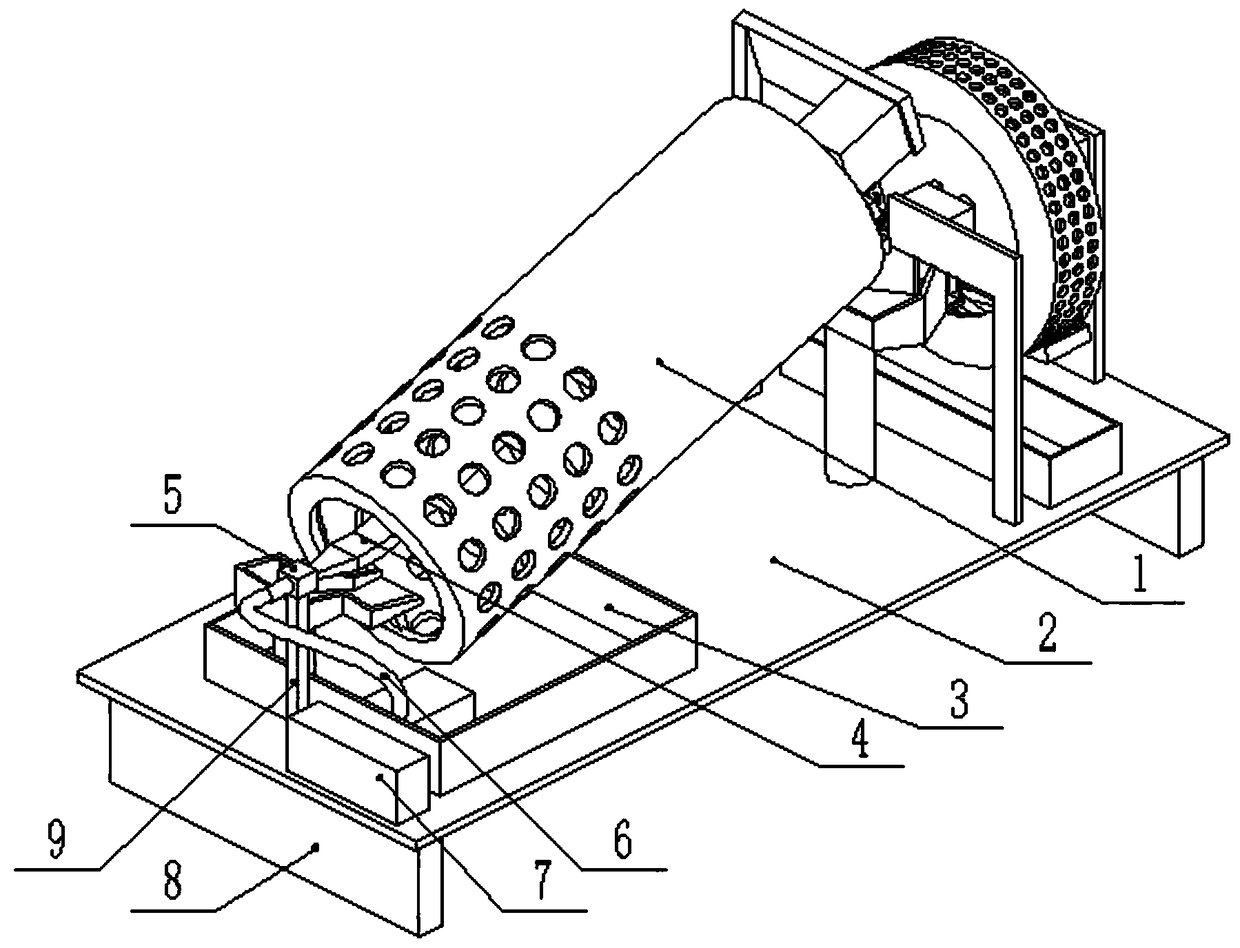

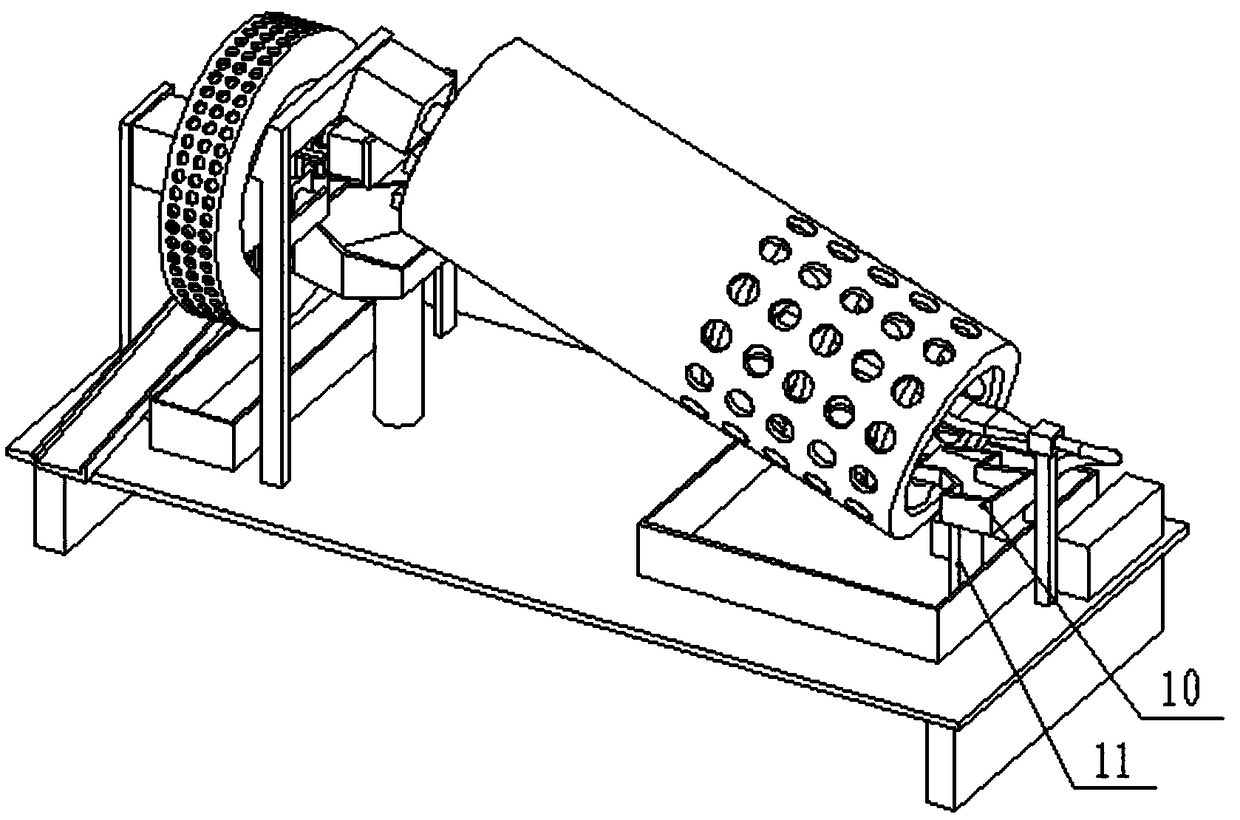

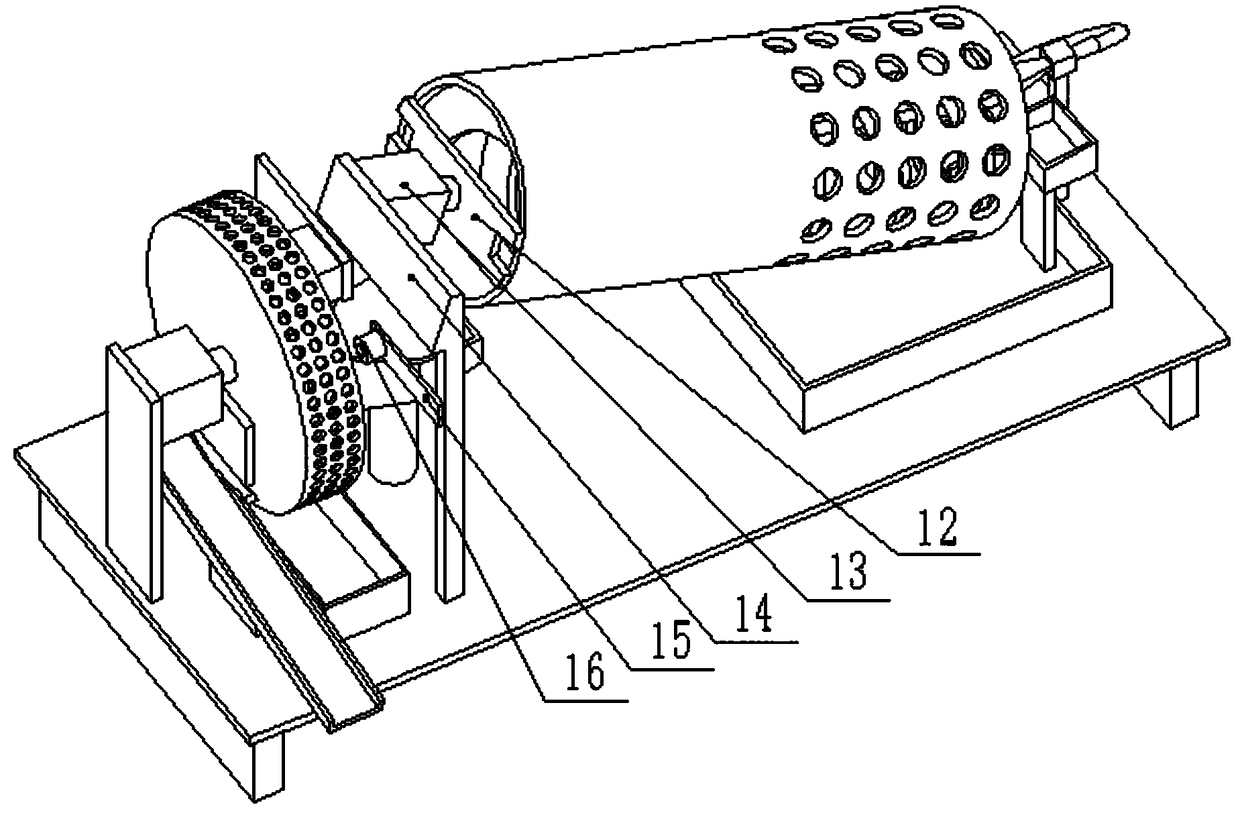

[0022] The present invention is realized through the following technical solutions:

[0023] An energy-saving rice cleaning device for food processing, comprising a drum 1, a workbench 2, a clean water tank 3, a water spray pipe 4, a water pump 5, a water inlet pipe 6, a controller 7, legs 8, a first bracket 9, an inlet Material channel 10, second support 11, third support 12, first motor 13, fourth support 14, fifth support 15, humidity sensor 16, hot air blower 17, sixth support 18, discharge device 19, discharge channel 20. The seventh support 21, the eighth support 22, the waste water tank 23, the drying device 24 and the water purification device 25, the drum 1 is fixed below the third support 12, and it forms an angle of 45 degrees with the workbench 2, and the working The platform 2 is installed on the legs 8, the clean water tank 3 is installed on the left side of the workbench 2, it is located directly below the drum 1, the water spray pipe 4 is fixed on the front sid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com