Ceramic diaphragm with good bonding property, preparation method thereof and lithium ion battery containing ceramic diaphragm

A ceramic diaphragm and combined technology, which is applied in the direction of secondary batteries, battery pack components, circuits, etc., can solve the problems of high energy consumption cost of ceramic diaphragm drying, unfavorable battery cycle rate performance, and decreased heat resistance of ceramic diaphragms. Achieve the effects of reducing the difficulty of attachment, strong adhesion, and reducing polymerization energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] (2) Preparation of the first water-based slurry: Add ceramic powder, graphene, water-based polyurethane-acrylic resin emulsion, sodium m-carboxybenzenesulfonate, and silane coupling agent to one of the aqueous solutions prepared in step (1). Prepared into the first aqueous slurry;

[0048] (3) Preparation of the second water-based slurry: Add ceramic powder, water-based polyurethane-acrylic resin emulsion, sodium m-carboxybenzenesulfonate, and a silane coupling agent to another group of aqueous solutions prepared in step (1). The second aqueous slurry;

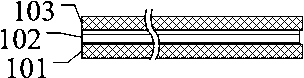

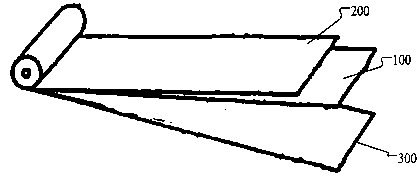

[0049] (4) Preparation of ceramic diaphragm: using a conventional diaphragm as a substrate, apply the first aqueous slurry obtained in step (2) on the diaphragm to form the first aqueous slurry coating, and then coat the first aqueous slurry after drying. The coating is coated with the second water-based slurry to form the second water-based slurry coating, so that a ceramic diaphragm with good adhesion can be obtained...

Embodiment 1

[0058] The preparation method of the good ceramic diaphragm of the present invention comprises the following steps:

[0059] (1) Preparation of aqueous solution: prepare a 4% aqueous solution with thickener and deionized water, and divide the obtained aqueous solution into 2 groups for later use;

[0060] (2) Preparation of the first water-based slurry: Add ceramic powder, graphene, water-based polyurethane-acrylic resin emulsion, sodium m-carboxybenzenesulfonate, and silane coupling agent to one of the aqueous solutions prepared in step (1). Prepared into the first aqueous slurry;

[0061] (3) Preparation of the second water-based slurry: Add ceramic powder, water-based polyurethane-acrylic resin emulsion, sodium m-carboxybenzenesulfonate, and a silane coupling agent to another group of aqueous solutions prepared in step (1). The second aqueous slurry;

[0062] (4) Preparation of ceramic diaphragm: using a conventional diaphragm as a substrate, apply the first aqueous slurr...

Embodiment 2

[0068] The preparation method of the good ceramic diaphragm of the present invention comprises the following steps:

[0069] (1) Preparation of aqueous solution: prepare a 4% aqueous solution with thickener and deionized water, and divide the obtained aqueous solution into 2 groups for later use;

[0070] (2) Preparation of the first water-based slurry: Add ceramic powder, graphene, water-based polyurethane-acrylic resin emulsion, sodium m-carboxybenzenesulfonate, and silane coupling agent to one of the aqueous solutions prepared in step (1). Prepared into the first aqueous slurry;

[0071] (3) Preparation of the second water-based slurry: Add ceramic powder, water-based polyurethane-acrylic resin emulsion, sodium m-carboxybenzenesulfonate, and a silane coupling agent to another group of aqueous solutions prepared in step (1). The second aqueous slurry;

[0072] (4) Preparation of ceramic diaphragm: using a conventional diaphragm as a substrate, apply the first aqueous slurr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com