Efficient filtering centrifuge capable of conducting air blowing

A high-efficiency filtration and centrifuge technology, which is applied in the field of centrifuges, can solve the problems that the separation capacity and separation effect cannot be further improved, and the dryness requirements of materials cannot be applied, so as to increase the evaporation area of water, reduce the filtration resistance, and reduce the humidity. The effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the embodiments shown in the drawings.

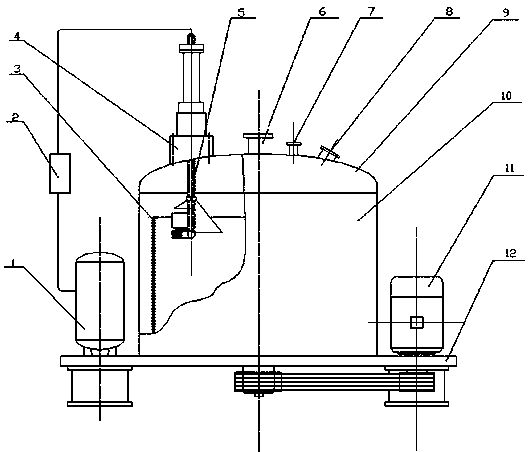

[0018] The present invention proposes a new filter centrifuge with a blower device based on the above idea. The centrifuge is composed of a base 12, a casing 10, a cover 9, a rotating drum assembly 3, a power mechanism 11, and a blast system. The cover 9 is provided with a feed port 6, an exhaust port 7, and a window 8. And scraper holder 4.

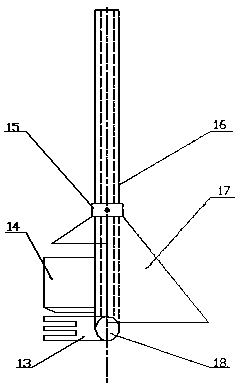

[0019] A scraper bar 16 is provided on the scraper seat, and a mechanical transmission mechanism or a hydraulic transmission mechanism is provided in the scraper seat, which can make the scraper bar produce axial and radial displacement, thereby adjusting the distance between the scraper and the filter medium during unloading. The scraper bar is a hollow tube, which is connected to a heater and an air compressor through a hose to introduce air into the drum.

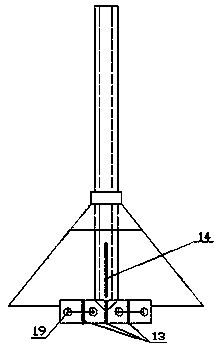

[0020] An umbrella-shaped baffle 17 is installed at the lower p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com