Drying device for chemical raw material processing

A chemical raw material and drying device technology, applied in the direction of drying gas arrangement, dry solid material, dry cargo handling, etc., can solve the problems that chemical raw materials cannot be fully dried, raw materials cannot be dispersed, and affect processing and use, etc., to achieve convenient screening Separation and drying, improve the drying effect, improve the effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

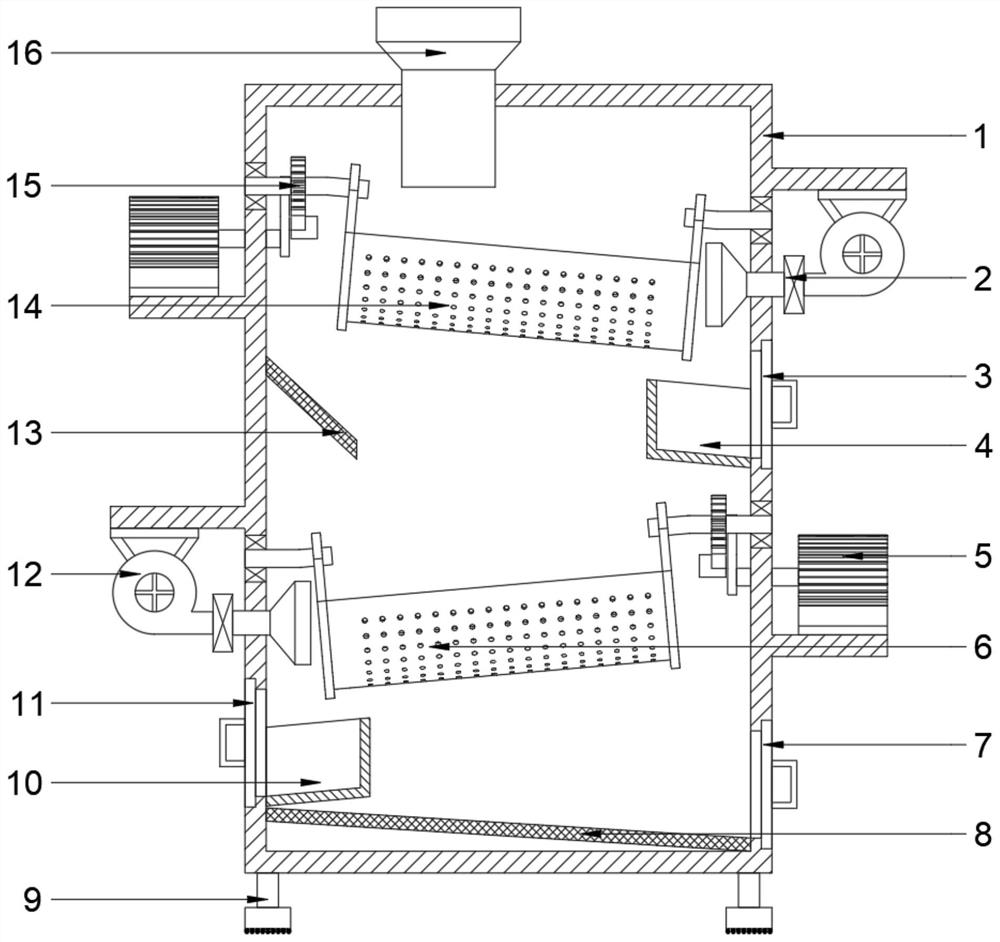

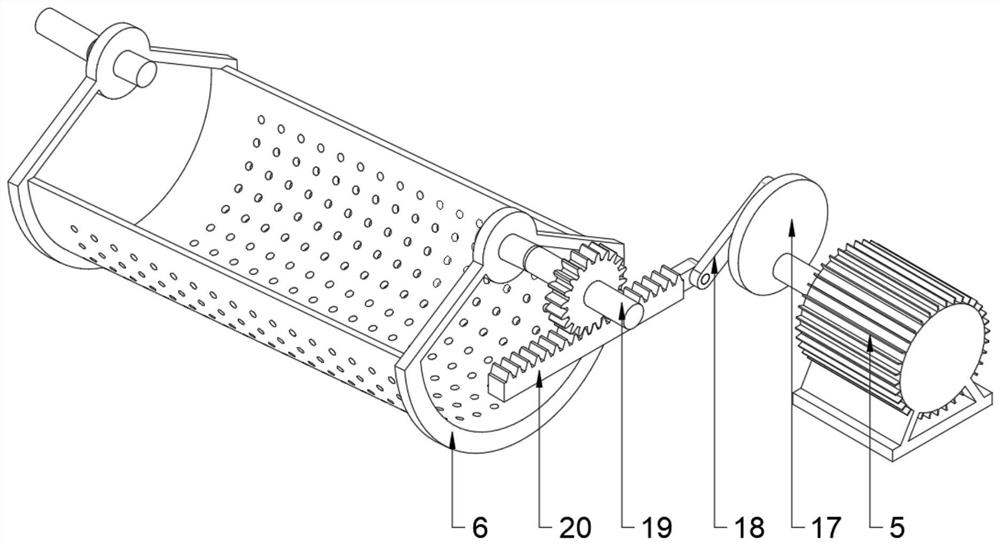

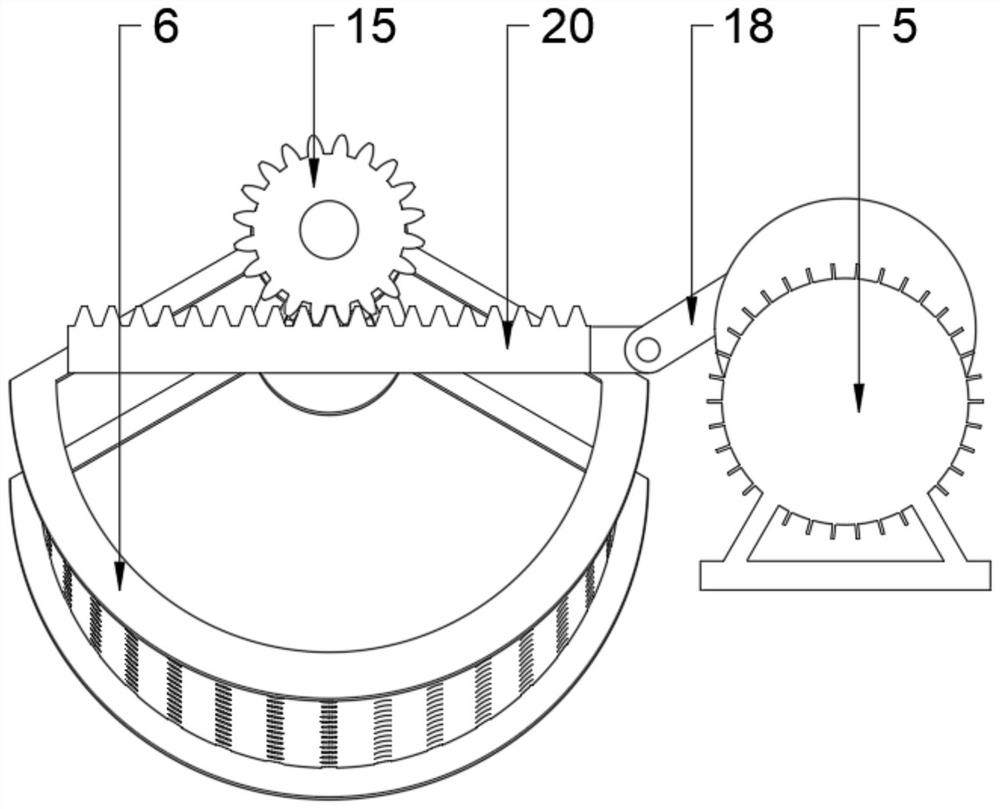

[0024] see Figure 1~3 , in an embodiment of the present invention, a drying device for processing chemical raw materials includes a drying box 1 and a screening assembly and a blowing assembly arranged inside the drying box 1, and the screening assembly includes a first pendulum screen 14 and a second pendulum screen Sieve 6, the two ends of the first swing sieve 14 and the second swing sieve 6 are fixedly provided with a rotating shaft 19 and are rotated and installed on the side wall of the drying box 1 through the rotating shaft 19, the first swing sieve 14 and the second swing sieve 6 It is arranged obliquely in the drying box 1 and the first swing sieve 14 is located above the second swing sieve 6. The first swing sieve 14 and the second swing sieve 6 also respectively offer multiple groups of swing sieve holes and the first swing sieve 14 The aperture of the pendulum sieve on the top is greater than the aperture of the pendulum sieve on the second pendulum sieve 6; Desc...

Embodiment 2

[0032] see figure 1, in the embodiment of the present invention, a drying device for processing chemical raw materials, in order to ensure the working efficiency of the device and improve the drying effect of raw materials, on the basis of embodiment 1, the blowing assembly also includes a heating device 2, the The heating device 2 is connected to the air outlet pipe and is located outside the drying box 1. When the drying speed needs to be accelerated, the heating device 2 is activated, and the blower 12 blows hot air to the raw material through the bell mouth to accelerate the water loss of the raw material and speed up the drying process. , improve work efficiency; two sets of heating devices can also be turned on at intervals, and used together to prevent excessive drying of raw materials and ensure the drying quality of raw materials.

[0033] The working principle of the present invention is:

[0034] During work, open the feed gate of feed hopper 16, feed into drying b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com