Rotary dryer

A dryer and rotary technology, applied in the field of dryers, can solve the problems of not being able to meet the drying needs of sticky and wet materials, small friction, poor drying and conveying effects, etc., and achieve simple structure, Increase friction and ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

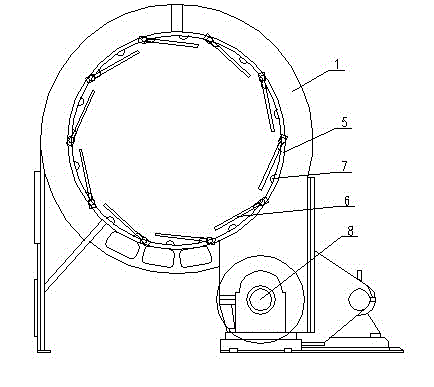

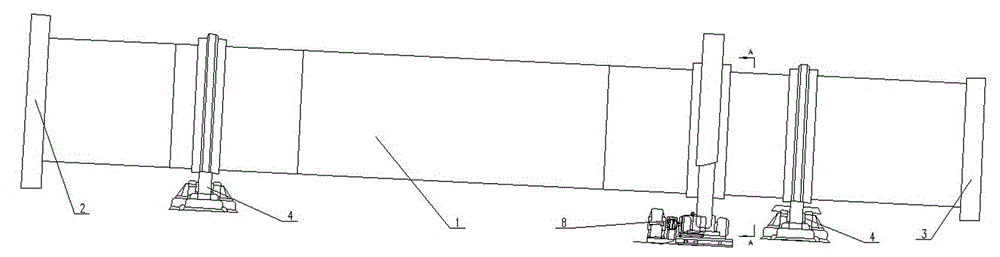

[0010] like figure 1 , figure 2 As shown, the rotary dryer includes: a cylindrical cylinder 1, a feed inlet 2 arranged at one end of the cylindrical cylinder 1 and a discharge outlet 3 arranged at the other end of the cylindrical cylinder 1, the cylindrical cylinder The two ends of 1 are respectively supported obliquely on the ground by supporting wheel device 4, the position of the feed inlet 2 is higher, and the position of the discharge port 3 is lower, and an inner drum is arranged in the cylindrical cylinder 1 5. A number of stir-frying plates 6 and semicircular projections 7 are evenly arranged in the inner drum 5, and the inner drum 5 is connected with a conveying device 8 arranged on the ground.

[0011] When in use, the transmission device 8 drives the inner drum 5 to rotate at a high speed, and the materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com